(L/EP) Defense Energy Program Policy Memorandum (DEPPM) 89-1

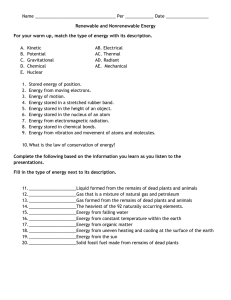

advertisement

THE OFFICE OF THE ASSISTANT SECRETARY OF DEFENSE WASHINGTON, D.C. 20301-8000 PRODUCTION AND LOGlSTlCS (L/EP) Defense Energy Program Policy Memorandum (DEPPM) 89-1 MEMORANDUM FOR DEFENSE ENERGY POLICY COUNCIL SUBJECT : Petroleum Quality Information System (PQIS) References: (a) Logistics Management Institute (LMI) Report AL628R1, "Petroleum Quality Information System Requirements and Recommended Design," December 1987 (b) LMI Report AL628TR1, "PQIS Aviation Turbine Fuel Prototype User's Guide and Reference Manual," February 1988 PURPOSE: This DEPPM establishes the requirement for PQIS. BACKGROUND: PQIS is planned as an automated information management system that integrates dissimilar Government and private sector petroleum product quality control and surveillance data into a standardized format. PQIS information would be available to DoD logistics and technical personnel for their use in identifying, investigating, and resolving fuel related equipment problem experienced within DoD. At the request of the Energy Policy Directorate, OASD(P&L), the LMI: (1) reviewed existing petroleum quality control monitoring programs, systems, and forms currently in use in the Military Services and the Defense Logistics Agency, Defense Fuel Supply Center (DFSC), and used these findings to develop functional requirements for alternative methods of designing PQIS (reference (a)), (2) developed a prototype PQIS and installed it at DFSC on a trial basis, and (3) prepared a draft PQIS prototype users manual (reference (b)), and provided it to DFSC to assist them in operating the prototype system. DISCUSSION: During March-May 1988, the Energy Policy Directorate conducted a survey of potential PQIS users to determine the requirement for: (1) PQIS in general, (2) alternative system designs for PQIS, and (3) standardization of petroleum quality data. m All respondents agreed on the need for PQIS in tracking DoD fuel quality trends. m All respondents agreed on the need to develop a standardized, automated fuel quality test form for data entry to PQIS. Formatting this form on a PQIS data entry disk, fuel quality data would be electronically encoded as close to the point of origin as feasible, e.g., at the refinery and laboratory. The form would use the American Society for Testing and Materials Form D1655 as a guide, also capturing essential data elements found on Government forms currently in use. Also, the form would be flexible enough to report results from atypical tests. Adoption of an automated means for reporting automated fuel quality test data would be a major step forward in transitioning to a paperless Defense fuel acquisition process. The capability to enter data at DFSC automatically should be present. m Respondents addressed recommendations concerning: PQIS costs/benefits, interaction with other data bases, size of the system, and origin of test reports. These are addressed below in responsibilities. POLICY: DFSC shall be responsible for designing the PQIS. A centralized PQIS database shall be maintained at DFSC. PQIS users shall have access to the database for performing analyses. A standardized, automated method of entering petroleum quality data to PQIS shall be developed. As appropriate, work with the American Petroleum Institute to develop U.S.-wide Electronic Data Interchange standards for fuel quality. These data shall be electronically recorded and validated as close to their source as feasible. RESPONSIBILITIES: In accordance with reference (a) and Enclosures 1 and 2, the following steps shall be taken to make PQIS operational: 1. The Director, Energy Policy, OASD(P&L) shall: a. Finalize the PQIS prototype users manual (reference (b)), with input from the Commander, DFSC. (complete) b. Develop a standardized, automated method of entering petroleum quality data to PQIS in coordination with the Military services. (LMI AL628) 2. The Commander, Defense Fuel Supply Center shall: Phase I a. Utilize and evaluate the PQIS prototype and prototype users manual, and advise the Director, Energy Policy, OASD(P&L) of necessary improvements. b. Prepare PQIS system design specifications. (DLA DL903) C. Develop a cost/benefit analysis for the hybrid micro/minicomputer PQIS design alternative. d. Report to the Defense Energy Policy Council (DEPC) on DFSC full implementation by September 1, 1989. Pending DEPC approval, Phase II is executed. Phase II e. Develop PQIS operational software packages, based on the PQIS system design specifications (above) in coordination with the Military Services. f. Develop a PQIS users manual. g. Distribute the PQIS users manual and operational software packages to PQIS users by August 1, 1990. h. Establish PQIS in an operational mode by October 1, 1990. 3. Defense Energy Policy Council Members shall identify to Director, Energy Policy, within 30 days of the date of this DEPPM, individuals with whom the Directorate for Energy Policy, OASD(P&L), and DFSC can consult in executing the above responsibilities. Also, these individuals will participate in a review of the proposed system at the end of Phase I (see paragraph 2.d. above) prior to entering Phase II. Enclosure ENCLOSURE 1 PETROLEUM QUALITY INFORMATION SYSTEM SURVEY QUESTIONS Numbers below represent respondents' composite preference for the specific item listed (% percent) 1. What products are you interested in: 11 56 F76 56 FS1 MG1 1 1 JP4 JP5 67 DF1 33 FS2 11 MG3 11 44 FS4 JP8 67 DF2 11 MG4 11 11 MUP 11 DFA 33 FS5 Jet A 56 11 MUR 11 Jet A1 44 DFW 33 FS6 Other Jet B 44 NSF 33 FSL 11 RJ-4 11 2. What sources of data are of interest: DD Form 250-1 or DD Form 250/AFTO 456 78 Loading report 67 Transfer report 78 Discharge report DoD laboratory reports 67 Problem test reports Dormant storage reports 78 3. What system functions would you require: 56 a. Dataentry b. Data validation 56 c. Print test report 67 d. Desktop publishing 44 e. Retrieve test data Data: Test report Summary data Specific test data Statistical data Other Type: Refinery Destination Storage tank Test date Test value range Other f. Statistical analysis Weighted averages Trends Distributions Other 56 89 67 78 78 100 89 67 67 56 78 44 44 JP-10 JP-7 JPTS JP-9 RP-1 Lube Oils IF0 FSII Coal 22 22 11 11 11 11 11 11 11 PETROLEUM QUALITY INFORMATION SYSTEM SURVEY QUESTIONS d. Data storage/transfer capability 44 Magnetic tape 22 Disc cartridge, Floppy disc 89 7. What other computer support is available to you a. Hardware Minicomputer Mainframe computer Other b. Software Database management Statistical analysis Programming languages Other c. Data storage/transfer Magnetic tape Disc cartridge Floppy disc DDN 8. 44 44 11 44 33 56 0 56 33 33 44 PQIS Alternative Evaluation. Numbers below represent composite ranking of alternatives by all respondents. Please rank the alternatives in order of preference (1,2,3,4,etc.): Microcomputer Systems Stand-alone system Local area network Decentralized system Wide area network Minicomputer System Mainframe Computer System Micro/Minicomputer System Micro/Mainframe System Micro/Mini/Mainframe System 4.0 5.0 3.6 4.6 6.0 7.4 3.5 5.0 2.1 PETROLEUM QUALITY INFORMATION SYSTEM SURVEY QUESTIONS 4. Downloading requirements 5. 6. a. Test reports All reports Specific reports 44 67 b. Data elements All test results Specific tests Other 67 56 11 Resident database content a. Current test data Loading Transfer Discharge Problem reports Dormant storage 56 44 56 78 78 b. Historical test data Loading Transfer Discharge Problem reports Dormant storage 56 44 56 78 78 What microcomputer equipment do you currently have: a. Computer Hardware (specify manufacturer & model number) 22 PC XT(8086/8088) 89 PC AT(80286) 0 386(80386) 11 Other b. c. Computer Storage Main memory Extended memory Floppy disc Hard disc Disc cartridge Computer Software Database management Data analysis Statistical analysis megabytes megabytes kilobytes megabytes megabytes 89 56 56 ENCLOSURE 2 PETROLEUM QUALITY INFORMATION SYSTEM (PQIS) SURVEY COMMENTS The following synopsizes comments received from potential PQIS users in response to a February 22, 1988, memorandum from the Director, Energy Policy, OASD(P&L), to the Defense Energy Action Group, requesting same. A glossary of acronyms related to each respondent is provided at the conclusion of this paper. A. General 1. LMI did a thorough job of researching and analyzing computer systems and their capabilities. Army supports PQIS and will use the system when it is available. (BRDEC) 2. PQIS could be advantageous to Navy in reviewing quality data and transaction histories (when working quality/use waivers) and evaluating performance of quality surveillance responsibilities at petroleum terminals. (CNO) 3. PQIS is needed urgently by Navy for the identification, investigation, and resolution of fuel related airframe and engine equipment problems of the fleet. If updated regularly, PQIS would improve Navy’s efficiency and response time in resolving these problems, and would ensure the currency of dormant storage trending data. (NAVAIR) 4. Distribution of PQIS software to personal computer-equipped end users should be hastened. (NPO) 5. Use of PQIS by the Air Force would be limited to the following: (a) annual review of summary reports for JP-4 and JP-8 fuels, (b) identification (by DFSC) of fuel suppliers, shippers, and terminals experiencing fuel quality problems, and (c) resolution by DFSC, Air Force, and other Military Service3 of such problems. Based on this limited degree of Air Force usage, PQIS should be scaled down. (AFSC) PQIS is a system that will be extremely useful in tracking 6. fuel quality trends. (DLA) B. System Design 1. The micro/mini/mainframe systems option appears to be the best alternative when considering data entry and validation, data storage and retrieval, and data analysis. (BRDEC) 2. The micro/mini/mainframe hybrid PQIS would have all the capabilities needed by Navy. (NAVAIR) 3. The micro/mini/mainframe hybrid PQIS is not required. RATIONALE: Air Force requires only annual summary data for JP-4 and JP-8. For Air Force needs, PQIS can be limited to: (a) fuels in dormant storage, (b) current year data, and (c) summary data for past years. (AFSC) 4. PQIS should be designed as a centralized system for petroleum product quality data storage, retrieval, and analysis. (BRDEC) 5. DFSC should be responsible to maintain PQIS as a centralized data base for all fuels. RATIONALE: Assigning DoD Components the responsibility to manage PQIS data for individual petroleum products (i.e., decentralization) would: (a) result in a greater cost to the Government due to duplication of effort at each data management location (requiring more manpower overall) to maintain separate data management staffs than would be required at one central location and (b) unnecessarily complicate data entry, validation, and transmission by terminal operators who need to input and receive data on a wide range of petroleum products. (CNO) 6. PQIS should become a centralized system. RATIONALE: DFSC should retain responsibility for PQIS as part of its role as the single integrated materiel manager for bulk petroleum fuel. (NPO) It may be advantageous to link PQIS with DFAMS transactional 7. inputs. RATIONALE: Both systems would be on-line at petroleum terminals. (CNO) If PQIS were linked to DFAMS, this would justify centralized 0. systems management (including data entry). RATIONALE: PQIS and DFAMS would be colocated at DFSC. (NAVAIR) 9. PQIS should be capable of receiving data from DFAMS. RATIONALE: Much of the contractor data and storage location data is maintained in DFAMS. Because payments are made through DFAMS, the linking of these two systems would also provide a method for determining receipt of procurement test reports. (DLA) 10. Attention should be given to obtaining correlating information from PQIS and DFAMS, in order to check the completeness of PQIS. RATIONALE To ensure data completeness, PQIS should have a mechanism for cross-checking refiners' deliveries of petroleum products to DoD and the volumes and number of shipments for which DFSC is paying these refiners. Navy has not had success in its efforts to obtain such correlating data from DFAMS, however. (NAVAIR) C. Data Entry: Standardization and Automation 1. A standardized method of recording petroleum product quality data throughout DoD is needed. (BRDEC) 2. Standardization (with automation at the earliest possible point of data entry) of DoD petroleum product quality data units, format, and reporting procedures should be pursued. (CNO) 3. PQIS data should be encoded electronically as close to the point of origin as possible. RATIONALE: Ensure that the database up-dated on as close to a real time basis as possible. (NAVAIR). 4. Fuel quality data entry should be automated (e.g., using a PQIS data entry disk) and performed as close to the source as practicable (e.g., at the refinery and the Region). RATIONALE: Neither DFSC nor the Military Services headquarters are staffed to key-in this data to PQIS. Data entry timeliness and integrity could be accomplished by requiring data entry on a disk: (a) by the refinery personnel under the product acceptance provisions of the contract with the refiner, (b) at fuel transfer points and final destination by Regional quality assurance representatives, and (c) at DoD laboratories by Military Service laboratory personnel. (DLA) An automated fuel quality test form should be developed using 5. ASTM D1655 as a guide. All fuel quality data could be transferred easily to the PQIS computer, avoiding all manual data entry at all points -- including fuel suppliers. (AFSC) 6. An automated, uniform petroleum quality control test report should be: (a) developed in coordination with ASTM and (b) flexible enough to permit recording of results from atypical tests, i.e., new tests or nonstandard tests performed in conjunction with Unique fuel quality problems. (DLA) 7. If an automated, uniform petroleum quality control test report were developed to replace the DD250 and DD250-1 in fuel procurement, DLA would want to consider automating the DD250 throughout all DLA Centers. (DLA) D. Special Concerns 1. A cost/benefit analysis of PQIS should be performed. (CNO) 2. PQIS operating costs should be shared by all users of the system. One method could be to treat the procurement test reports as technical data and have DFSC charge for the procurement and distribution of the data as a stock fund type item. (DLA) 3. PQIS should be limited, at first, to dormant fuel stocks. RATIONALE: This will provide an opportunity to optimize the system’s operations using a moderately-sized data base. (DLA) 4. PQIS should be capable of receiving input from the waivers and deviations files maintained by DFSC. RATIONALE: A waiver, deviation, or exception can affect the types of fuel quality tests performed and/or the test limits. (DLA) If DLA’s DMINS is to be used in conjunction with PQIS, there 5. may be limitations with regard to DBASE III data transfer and the number of users of the system. (DLA) Attention should be directed to a recurrent problem 6. experienced with JP-5, i.e., irregular transmission of test reports by overseas refineries. (NAVAIR) 7. PQIS should eventually include laboratory reports from ship and Naval air station monthly fuel samples. RATIONALE: Completeness. (NAPC) 8. Where "laboratory quality control test reports" are used as a source of PQIS data, in the case of the Air Force, the only reports that may be used are generated quarterly under the direction of the Laboratory Branch, Energy Management Division, Air Logistics Center, San Antonio, Texas (SA-ALC/SFTL). To be useful, the SA-ALC/SFTL reports should be compared to suppliers* reports for the same batches of fuel. (AFSC) Glossary of Respondent Acronyms AFSC Aero Propulsion Laboratory, Air Force Wright Aeronautical Laboratories, Air Force Systems Command, Wright-Patterson Air Force Base, Ohio (Fuels and Lubrication Division) BRDEC U.S. Army Belvoir Research, Development and Engineering Center, Fort Belvoir, Virginia (Fuels and Lubricants Division) CNO Office of the Chief of Naval Operations, Pentagon, Washington, D.C. (Petroleum and Transportation Management Branch) DLA Defense Logistics Agency, Cameron Station, Alexandria, Virginia (Defense Fuel Supply Center) NAPC Naval Air Propulsion Center, Trenton, New Jersey NAVAIR Naval Air Systems Command, Washington, D.C. NPO Navy Petroleum Office, Cameron Station, Alexandria, Virginia