Airfield Damage Repair Operations OPR: AFCESA/CEXX

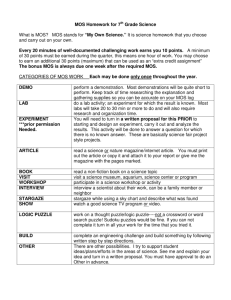

advertisement