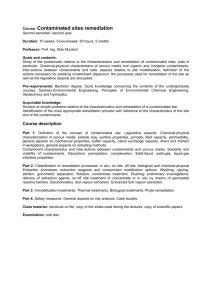

Develop Installation Restoration Design Technical Guidance Remediation Alternatives Data Draft

advertisement