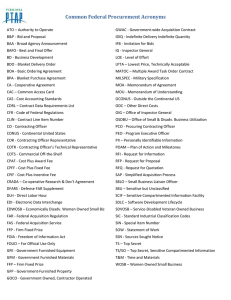

SUSTAINABLE FEDERAL FACILITIES A Guide to Integrating Value Engineering, Life-Cycle

advertisement