SAFETY POLICY ...

advertisement

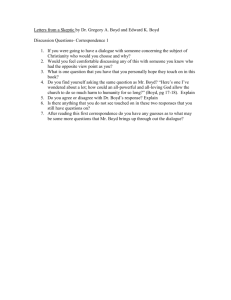

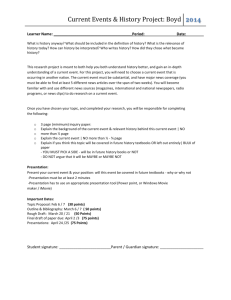

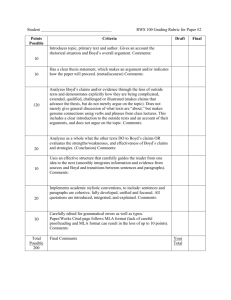

SAFETY POLICY Mechanical Engineering Department APPROVED: 4/1/03 This policy will apply to the following rooms: 0047 Black – Student Fabrication 0083 Black – ME270 Lab 1051 Black – Engle Lab 1070 Black – Machining Processes 1092 Black – Welding and Material Testing 1095 Black – Polymer Processing and Heat Treatment 1098 Black – Casting Boyd Lab BASIC SAFETY POLICY WARNING – Students who fail to follow the safety rules will be asked to leave the lab area. Egregious violations of safety policy could lead to a ban from all lab facilities. BASIC SAFETY RULES – All labs at all times: • WORKING ALONE – Students are not allowed to work alone in any lab except for the following cases: simple assembly without power tools, use of the sand blaster. • USE OF EQUIPMENT – Never attempt to operate any equipment for which you have not been approved (see access policy). • EYE PROTECTION - Approved safety glasses (ANSI C87.1) or goggles must be worn at all times. Safety glasses should have wrap around side shields. Students are responsible for acquiring, maintaining and having safety glasses available. • FOOTWEAR – Shoes must be made of leather and cover the entire foot. Leather athletic shoes ARE permitted in the welding or casting labs. Over the ankle work shoes are strongly recommended. • CLOTHING – Long pants and socks are recommended when using machine tools and required for welding. When using rotating equipment dangling or loose clothing will not be allowed and neckties must be removed. Specialized clothing will be provided in certain areas as required (i.e. gloves, spats, face shields and coats). • HAIR – When using rotating equipment and welding long hair must be tied back or contained by a cap so that it will not cause a hazard. • JEWELRY – Any jewelry that might cause a hazard must be removed while in the laboratory. OTHER CONSIDERATIONS: • Even in cases where direct supervision is not required the student should have approval from a staff or faculty member before using the lab. • When leaving the lab students should clean up the area, turn off equipment and lights and lock the door. • Any equipment problems or breakage should be reported immediately to appropriate staff members • Assembly/disassembly activities should be done on appropriate surfaces. Do not use tables of machine tools or test equipment, computer work tables, floor areas with high traffic, etc. • Permission must be given by appropriate staff before any tools can be removed from a lab area. ACCESS POLICY ACCESS LEVEL 1- Entry Level This pertains to all students using any of the manufacturing lab areas. The sequence listed below will usually occur in ME 270 or Engr 170 for undergraduate students and ME 600 for graduate students. In all cases the student is responsible for completing the sequence. Activities and Equipment: • Demonstration activity in any laboratory • Fully supervised activity in any lab • Use of hand tools for assembly/disassembly (Boyd, 0047, 0083, 1070, 1092) Guidelines: • Review of “The Safety Factor” videotape and successful completion of quiz • Students name will be placed on departmental list. • Visit to shop in small groups to reinforce safety issues and be introduced to shop environment. • Students will be given photo identification badge that must be worn whenever in a lab. ACCESS LEVEL 2 – Advanced Level This is required for students to use the following equipment without supervision. Activities and Equipment (approved areas): • Drill press, cut off saws, grinders, sanders (Boyd, 0047, 1070) • Power hand tools: drills, grinders, reciprocating saw (Boyd, 0047, 0083, 1070, 1092) • Wire feed welders (1092) • Sand blaster (1098) • Paint booth (0047) Guidelines: • Students will be given a tutorial (basic use, safety considerations) on power tools. After demonstrating to the staff member the required proficiency a notation will be placed on the student’s ID badge. • Students will be given a tutorial (basic use, safety considerations, proper attire and equipment) on the wire feed welder. After demonstrating to the staff member the required proficiency a notation will be placed on the student’s ID badge. ACCESS LEVEL 3 – Technical Staff Staff members who are qualified to use and supervise others on the following equipment. Activities and Equipment: • Foundry equipment (1098) • Heat Treatment Equipment and Injection molding machine (1095) • Material Testing (1092) • CNC machine tools (Boyd, 0047, 1051) • Manual machine tools-Lathe, milling machine (Boyd, 0047, 1070) Guidelines: • The above mentioned equipment can only be used by students with access level 2 under the supervision of someone with access level 3. • In the special case of manual machine tools, supervision can be provided by teaching assistants who are trained and approved by staff. The TA would be given an ID badge.