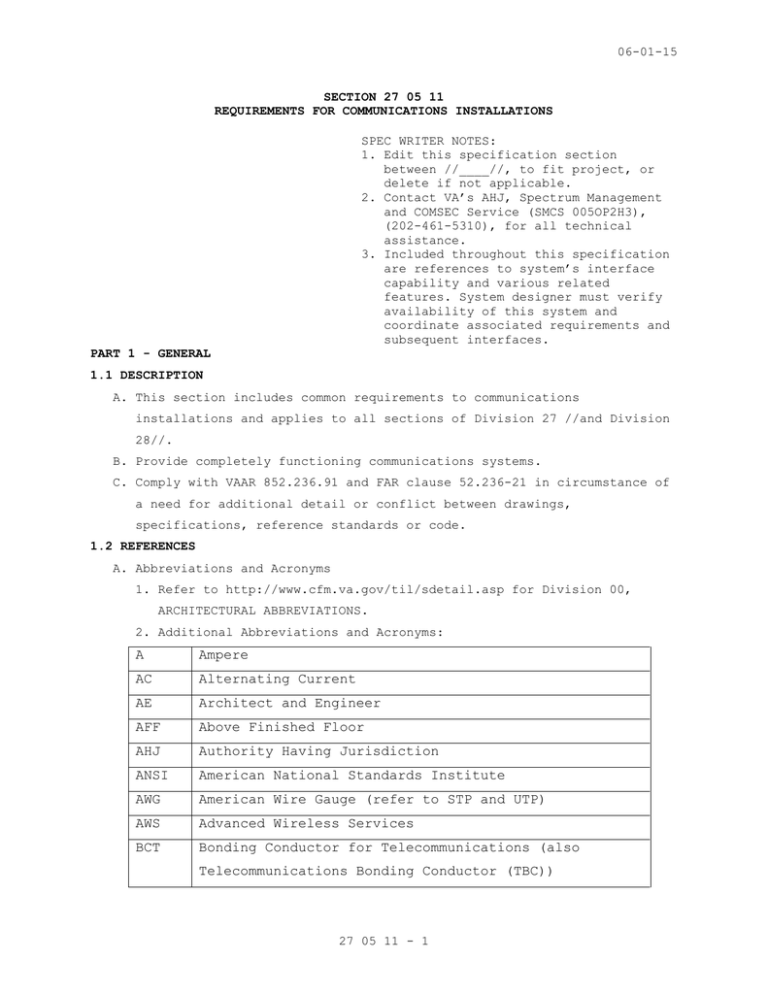

06-01-15 SPEC WRITER NOTES: 1. Edit this specification section

advertisement