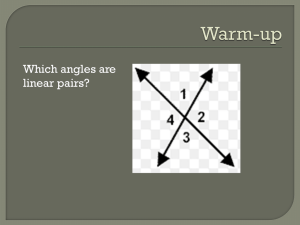

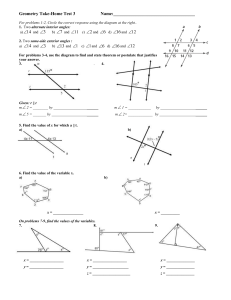

S T A N D A R D S

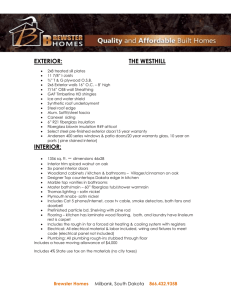

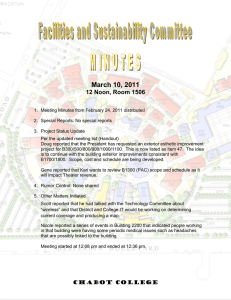

advertisement