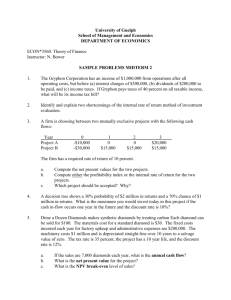

} TM 5-609 NAVFAC MO-125 C2

advertisement