Keeping Pace with Aseptic Fill Finish Operations Presented By:

advertisement

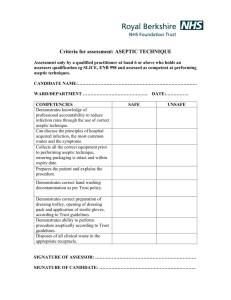

Keeping Pace with Aseptic Fill Finish Operations in an Evolving Regulatory Environment September 30, 2010 Presented By: Roshni Dutton, PhD PEng PMP SNC-LAVALIN Pharma Central Canada Chapter Aseptic Filling September 30, 2010 Keeping Pace with Aseptic Fill Finish Operations in an Evolving Regulatory Environment OUTLINE Aseptic liquid filling line guidelines: EMA, FDA, HC QbD and PAT: ICH 7, 8, 9, 10 QbD/PAT Examples Check Weigh Vision System Dosing System Central Canada Chapter Aseptic Filling September 30, 2010 1 Aseptic Processing Guidelines Regulations set forth WHAT must be complied with Guidelines set forth suggestions of HOW to comply “Unless specific regulatory or statutory requirements are cited”, Guidelines do not comprise REQUIREMENTS. They are not PRESCRIPTIVE. Nevertheless, Guidelines are the output of Expert Working Groups, and offer sound advise based on their interpretation of the regulations and the technology state of the art at the time of writing. Compliance Inspections are generally conducted against Guidelines. Innovations that improve compliance with regulations are encouraged over adherence to guidelines. Central Canada Chapter Aseptic Filling September 30, 2010 2 Aseptic Processing Guidelines FDA Guidance for Industry: Sterile Drug Products Produced by Aseptic Processing – Current Good Manufacturing Practice 2004 EU Guidelines to Good Manufacturing Practice Medicinal Products for Human and Veterinary Use: Annex 1 – Manufacture of Sterile Medicinal Products (corrected version) 2008 HC Good Manufacturing Practices (GMP) Guidelines – 2009 Edition: Part 5.0 Sterile Products C.02.029 These documents primarily address aseptic filling lines Central Canada Chapter Aseptic Filling September 30, 2010 3 Aseptic Processing Guidelines: FDA FDA: Critical Area such as aseptic processing line should meet Class 100 (ISO 5) standards FDA: area immediately adjacent to the Critical Area should meet, at a minimum, Class 10,000 (ISO 7) standards under dynamic conditions. FDA: (where isolators are used), a Class 100,000 (ISO 8) background is commonly used. FDA: An aseptic processing isolator should not be located in an unclassified room FDA: Class 100,000 (ISO 8) is appropriate for less critical activities such as equipment cleaning FDA: “The use of the word should in Agency guidances means that something is suggested or recommended, but not required.” Central Canada Chapter Aseptic Filling September 30, 2010 4 Aseptic Processing Guidelines: EMA EMA: Aseptic preparation and filling Grade A (ISO 5) EMA: Background environment should be controlled and for aseptic processing at least Grade D (ISO 9) EMA: Partially stoppered freeze drying vials should be maintained under Grade A at all times EMA: Vials should be maintained in Grade A environment until cap has been crimped. Capping equipment should be located at a separate station equipped with adequate air extraction, which may not be able to meet Grade A conditions for non-viable particles in the “in operation” condition but should meet the microbiological requirements. Central Canada Chapter Aseptic Filling September 30, 2010 5 International Committee on Harmonization ICH includes representatives of: Regulatory Bodies Pharmacopeias Drug Industry Members From: USA, Canada Europe Japan Central Canada Chapter Aseptic Filling September 30, 2010 6 ICH Q7, Q8, Q9, Q10: The New Paradigm “risk-based” concepts and principles Central Canada Chapter Aseptic Filling September 30, 2010 7 ICH Q7, Q8, Q9, Q10: A Vision of the Future Old Approach Broad Concept Quality Systems Regulatory New Approach Remarks Quality decisions divorced from science and risk evaluation. Adherence to filing commitments. Quality decisions and filing commitments based on Process Understanding and Risk Management. Quality by Design. Design Space concept introduced to integrate process knowledge with regulatory evaluation. Post-factum sampling and quality testing. Process Validation. Management of variability Process control focused on critical attributes. Continuous Quality Verification. Quality by Design definition applied. Measure critical process parameters to control output product quality. Systems designed to inhibit changes & minimize business risks. Discourages improvement & innovation. Changes managed within company's quality system. Real time batch release feasible. Regulators and industry place higher reliance / trust / understanding on systems. Multidisciplinary evaluation and decision making. Compliance focus. Changes require prior approval. Regulatory scrutiny adjusted to level of Process Understanding. Continuous improvement allowed within Design Space. Requires mechanisms to communicate Process Understanding data ("inspectable rather than reviewable"). Central Canada Chapter Aseptic Filling September 30, 2010 8 ICH Q8: A Vision of the Future Design Space: The multidimensional combination and interaction of input variables (e.g., material attributes) and process parameters that have been demonstrated to provide assurance of quality. Central Canada Chapter Aseptic Filling September 30, 2010 9 ICH Q8: A Vision of the Future Quality: The suitability of either a drug substance or drug product for its intended use. This term includes such attributes as the identity, strength, purity. Quality by Design (QbD): Quality is achieved through controlling operation within the Design Space Central Canada Chapter Aseptic Filling September 30, 2010 10 ICH Q7 & Q8: A Vision of the Future Validation: A documented program that provides a high degree of assurance that a specific process, method, or system will consistently produce a result meeting predetermined acceptance criteria. Continuous Process Verification: An alternative approach to process validation in which manufacturing process performance is continuously monitored and evaluated. Central Canada Chapter Aseptic Filling September 30, 2010 11 ICH Q8: A Vision of the Future Process Analytical Analytical Technology Technology Process (PAT): (PAT): A system system for for designing, designing, analyzing, analyzing, and and A controlling manufacturing manufacturing through through timely timely controlling measurements (i.e., (i.e., during during processing) processing) of of measurements critical quality and performance attributes of Critical Process Parameters (CPP) that affect raw andQuality in-process materials andofprocesses Critical Attributes (CQA) the product. with the goal of ensuring final product quality. Central Canada Chapter Aseptic Filling September 30, 2010 12 ICH Q9: Quality Risk Management Process Optional but can benefit from its use! Central Canada Chapter Aseptic Filling September 30, 2010 13 ICH Q10: Pharmaceutical Quality System Central Canada Chapter Aseptic Filling September 30, 2010 14 ICH Q9: Quality Risk Classification (based on SUPAC and GAMP-4) Impact on Quality Quality by design + Systems approach High Medium Low Risk Likelihood Level 3 High Level 2 Medium Low Central Canada Chapter Aseptic Filling Level 1 September 30, 2010 15 ICH Q9: Quality Risk Priority (based on SUPAC and GAMP-4) Risk Classification High Medium Probability of Detection Low Quality by design + Systems approach High 3 Medium 2 1 Central Canada Chapter Aseptic Filling Low September 30, 2010 16 ICH Q7, Q8, Q9 Q10 Inter-relationship Opportunities to impact risk using quality risk management Q9 Design Process Materials Facilities Manufacturing Distribution Patient Q8 Q7 Central Canada Chapter Aseptic Filling Q10 September 30, 2010 17 Low t m pr ov em en ua li tin co n High Q10 Pharm.. Quality Systems Risk from Manufacturing site How Q9 interacts with Q8 and Q10 Q8 Pharmaceutical Development Low Using Q9 Quality Risk Management principles High Product / Process Risk Central Canada Chapter Aseptic Filling September 30, 2010 18 QbD/PAT Example One: Check Weighing Check Weighing, a well developed filling line In Process Control (IPC), is an example of QbD/PAT that is already in practice. Data capture, evaluation, and response: Real time in-line measurement Statistical interpolation and extrapolation Incorporation of continuous real time adjustment of fill volume Continuous verification A component of potential for real time release Central Canada Chapter Aseptic Filling September 30, 2010 29 QbD/PAT Example Two: Vision Systems Visual Inspection is a well established QC testing component of CQAs. Potential for Visual Inspection to be linked to CPPs, which for example might include: Stoppering pressure Lyo residual humidity etc Potential for Visual Inspection to be tied to real time adjustment Potential for Visual Inspection as a component of QbD/PAT Central Canada Chapter Aseptic Filling September 30, 2010 30 QbD/PAT Example Three: Dosing System The CPP of each unit operation within the process can affect the CQA The CPP of the Dosing System can affect CQA of protein products (Source: A-Mab A Case Study in Bioprocess Development 2009) Central Canada Chapter Aseptic Filling September 30, 2010 31 QbD/PAT Example Three: Dosing System (Source: A-Mab A Case Study in Bioprocess Development 2009) Central Canada Chapter Aseptic Filling September 30, 2010 32 QbD/PAT Example Three: Dosing System (Source: A-Mab A Case Study in Bioprocess Development 2009) Central Canada Chapter Aseptic Filling September 30, 2010 33 QbD/PAT Example Three: Dosing System Following investigative studies a Design Space for the Dosing System is specified in terms of CPP The CPP are measured and controlled in real time to maintain the operation within the Control Space Dark circles represent magnitude of protein aggregatation (Source: A-Mab A Case Study in Bioprocess Development 2009) Central Canada Chapter Aseptic Filling September 30, 2010 34 Developing a QbD/PAT System Identify CQAs Identify CPPs Define the Design Space Define the Control Space within the Design Space Continuous Verification: Continuously verify operation within the Control Space Continuous Improvement: Continuously refine the Control Space Central Canada Chapter Aseptic Filling September 30, 2010 34 Keeping Pace with Aseptic Fill Finish Operations in an Evolving Regulatory Environment CONCLUSION The evolving regulatory environment coupled with advancements in technology provide a unique opportunity in aseptic fill finish operations Central Canada Chapter Aseptic Filling September 30, 2010 35 Keeping Pace with Aseptic Fill Finish Operations in an Evolving Regulatory Environment Thank-You Central Canada Chapter Aseptic Filling September 30, 2010 36