IT-C-520B CANCELLATION October 5, 1988 COATING COMPOUND, BITUMINOUS, SOLVENT’

advertisement

IT-C-520B

CANCELLATION

October 5, 1988

FEDERAL SPECIFICATION

COATING COMPOUND, BITUMINOUS, SOLVENT’

TYPE, UNDERBODY

(FOR M3TOR VEHICLES)

This cancellation is approved by the Ccmdssioner,

Office of Federal Supply and Services, General

Services Achninistration.

Federal Specification TT-C-520B, dated February 25, 1973 is hereby canceled

and replaad by MIL-C-62218A, Corrosion Preventive Compounds, Cold Application

(For New and Fielded Motor Vehicles and Trailers), Type II - For fielded

v

Note from the webmaster:

MIL-C-62218A has been replaced by MIL-PRF-62218B;

MIL-PRF-62218B has been replaced by A-A-59295.

ehicles and Trailers.

DISTRIBUTION

unlimited*

STATEMENT A:

Approved

STORAGE: Most adhesives are temperature sensitive and

should be stored in a temperature and humidity controlled

depets. Unless otherwise specified on the package label or

marking, temperatures shall not exceed 60” F (15.6° C) and

the relative humidity shall not exceed 50 percent.

*US,

GOVERNMENT

PRINTING OFFICE:

1988

- 240-963/96613

●

TT.c-520B

February p, 1973

SUPERSEDING

Fed. Spec. TT-C-520A

June G, 1963

FEDERAL SPECIFICATION

COAT NG COMPOUND, BITUMINOUS,”

SOLVENT

UNDER60DY, (FOR MOTOR VEHlcLEs)

TYPE,

This

specification

Service,

General

was approved

by the

Services

Administration,

Commissioner,

for

the

Federal

use

of

all

Supply

Federal

agencies.

SCOPE AND CLASSIFICATION

1.

1.1

use

a

use

1.2

be of

coating

AIR

APPLICABLE

composition

G L -

General

Limited

an asphalt

deadener

two

REGULATIONS

Coating

following

covers

sound

provides

POLLUTION

Classification.

the

and

It

equipment.

under

Composition

Composition

2.

specification

protective

automotive

for

This

Scope.

as

use.

use (see

compound

the

compositions

(see

suitable

underbody

one

of

which

for

of

parts

is

suitable

6.7).

covered

specified:

compound

as

on

by this

specification

shall

6.7).

DOCUMENTS

The following documents, of the issues in effect on date of invitation for

2.1

bids or request for proposal, form a part of this specification to the extent

specified herein:

Federal

Specifications:

QQ-A-250/4

QQ-C-576

(IQ-s-698

PPP-C-96

PPP-D-729

-

PPP-P-704

-

Aluminum

Alloy

2024 Plate

and Sheet.

Copper,

Flat

Products

(Plate,

Bar,

Sheet

and Strip).

Sheet

and Strip,

Low Carbon.

Steel,

Cans; Metal , 28 Gage and Lighter.

Drums: Metal,

55-Gallon

(For Shipment

of Noncorrosive”

Material).

Shipping,

Steel

(1 through

12 Gallon).

Pails:

FSC

8030

TT-c-520B

Federal

Standards:

Fed.

Fed.

(Activit

Specificat

123 -

Marking

Std.

No.

Test

Method

Std.

Materials;

for

-

Shipment

Paint,

Varnish,

of

Inspection,

is

U.S.

(Single

for

sale

on

Government

copies

required

by

are

available

Offices

in

of

and Standards

and

includes

cumulative

a subscription

Printing

Office,

this

outside

without

charge

Boston,

New York,

and

the

at

basis

by the

Washington,

specification

activities

other

Federal

agencies).

(civil

Lacquer,

Sampling,

es outside

the

Federal

Government

may obtain

ons and Standards

as outl ined

under

General

Index

of Federal

Specifications

in the

Index.

The

Index,

which

issued,

ments,

Domestic

No.

141

Methods

and Related

and Testing.

copies

of

Information

Federal

in the

ndicated

ements

as

the prices

monthly

supp

of

Supel-intenden

D. C. 20402.

product

Government

specifications

for

at the General

Services

Washington,

DC.,

Atlanta,

Docu-

bidding

purposes

Adrninistration

Chicago,

Regional

Kansas City,

Fort Worth, Denver, San Francisco, Los Angeles, and Seattle, WA.

(Federal

Government

and Standards

established

Military

activities

and the

distribution

MIL-STD-105

-

Sampling

Attributes.

MI L-STD-147

-

Palletized

MI L-STD-290

-

(Copies

of

connection

the

2.2

Military

with

procuring

Other

the

Society

217 -

(Applications

Testing

and

2

the

issue

in effect

shall

apply.

D

of

Federal

and

Cone

for

Materials,

Procedures

and

Tables

for

Specifications

Standards

from

Inspection

or

as

on

directed

The

extent

for

Penetration

the

following

date

of

Testing

copies

by

specified

the

by

x 48”

(

Pallets,

and

Products.

Specifications

and Standards

specific

procurement

functions,

publications.

to

American

copies

and Containerized

Unit

Loads

40”

Runners,

or Pallet

Type

Base

Skids,

Packaging,

Packing,

and Marking

of Petroleum

agency

specification

posal

obtain

Federal

Specifications

in their

agencies.)

Standards:

Related

in

may

Index

of

points

of

should

1916 Race

contracting

document

herein.

invitation

and

required

should

Materials

Lubricating

by contractors

obtained

from

officer.)

forms

Unless

for

be

bids

(ASTM)

a part

otherwise

or

request

of

this

indicated,

for

pro-

Society

for

Standard

Grease

be addressed

to the

Street,

Philadelphia,

American

PA

19103.)

TT-C-520B

REQUIREMENTS

3.

3.1

be

Qualification.

a product

Products

Any

which

List

change

requal

within

at

in

is

the

the

ification.

manufacturing

3.2

time

fillers

set

formulation

The

Composition

solvents,

The compound

qualified

for

for

opening

of

a qualified

material

tolerances

supplied

to the

requirements.

and

furnished

listing

The

additives

under

this

specification

the applicable

Qualified

on

of

bids

(see

product

under

product

contract

receiving

compound

processed

4.4.2.1

will

to

shall

meet

and

shall

6.3).

necessitate

its

shall

be identical

qualification.

be

the

a mixture

of

requirements

asphalts,

of

this

specification.

3.2.]

Asphalts.

residuum

from

occurring

3.2.2

vacuum

may

be

The

volatile

shall

be

conform

L.

to

the

further

of

volatile

following

by

air-blowing

petroleum

or

the

naturally

processed.

portion

The

produced

distillation

of

the

petroleum

hydrocarbon

solvent

or

hydrocarbons

or other

solvents

Composition

also

used

asphalts

or

which

Solvents.

3.2.2.1

compound

solvents.

of a highly

content

of

requirements

shall

it

consist

shall

toxic

nature.

composition

by

volume

of

contain

L compounds

when

tested

as

4.6.3.

in

(a)

benzene:

Aromatic

compounds

8 percent

maximum.

(b)

(d)

Total

3.2.3

tos

and

s, nd and

tative

of

a+b:

Fillers.

fiber

3.3

with

Ethyl

benzene,

toluene

Solvents

with

an olefinic

6.8).

test

(see

(c)

negative

t

steam

bitumens

any suitable

no chlorinated

shall

The

the

other

fine

harsh

Quantitative

requirements

20

requirements.

of Table

and

or

more

carbon

branched

ketones:

or cyclo-olefinic

percent

The fillers

inert

mineral

abrasive

eight

20

type

except

ethyl

percent

maximum.

of unsaturation:

maximum.

shall

be short

which

shall

material

atoms

shall

asbestos

fiber

or short

pass

throuqh

a 325-mesh

not

The compound

I when tested

as

be

asbessieve.

usej.

shall

conform

in 4.6.

to

the

quan-

3

TT-c-520B

TABLE

1.

Quantitative

requirements

Requirements

Characteristics

Total

Minimum

solids,

Filler,

Weight

percent

percent

by

per gallon,

Flash

point,

to

of

of

compound

60

--

--

25

nonvolatile

100

millimeters

air

--

S2.O

dry,

38.5

hours:

touch

Practical

9.5

8.o

“F.

Consistency,

Drying

time,

Set

by weight

volume

pounds

Maximum

hardness~l

I/The

coating

is considered

—

pressure

between

the

thumb

but

the

film

is not

ruptured

to have

reached

practical

and the

finger

and none of

hardness

--

4

--

24

when

firm

shows a slight

tacky

condition,

the

coating

adheres

to the

finger.

3.4

Qualitative

3.4.1

show

Condition

little

curdling,

lumps or

3.4.2

tainer

or

no

livering,

skins.

in

in

vehicle

the

When

after

compound,

tested

a freshly

as

opened

separation,

Storage stability.

of

When

container.

settling

or

tested

4.6.8,

and

4.6.9,

in

the

compound

container,

caking,

as

six-months

in

full

shall

be

a full

shall

storage,

shall

shall

show

free

no

from

one-gallon

conthe

requirements

meet

3.4.3.

of

3.4.3

Spraying

continuous,

uniform,

surface.

3.4.4

Sag

test.

when suspended

be no flowing

3.4.5

Acid

shall

show

by solvent

3.4.6

steel

The

,

and

Corrosion.

and

properties.

and

When

or

tested

any

pinho”

ing

in

4.6.11

as

resistance.

attack

by

panel

The

compound,

aluminum.

strips

compound,

The

the

The

strips

heated

tested

steel

shall

but

fluids.

shall

as

strips

show

not

4.6.1o,

in

would

compound

shall

expose

shall

tested

as

the

in

be

in

4.6.13,

no more

immersed

shall

show

staining

in

the

no

not

trace

and

metal

sag

There

On removal

of

free

from

pitting

shall

be

the

not

after

spraying.

the

lower

half

of

compound,

test

surface

as

that

the

for

1 hour

immediately

up of the

coating

on

the

aluminum

prepared

from

tested

alkali

of

The

free

vertically

and piling

no signs

cleaning,

copper,

copper

similarly

4

requirements.

4.6.12,

the

or

coating

rusting.

corrode

of

corrosion.

corrosion

compound.

shall

panel.

than

I

TT-c-520B

3.4.7

shall

is

Fire

not

resistance.

support

The

combustion

compound,

for

more

tested

than

as

15

4.6.14,

in

seconds

after

may

the

char

but

flame

source

removed.

3.4.8

as

in

Resistance

4.6.15,

3.4.9

show

surface

at

flow

of

blistering

shall

be

free

from

3.4.11

not be

flake,

or

Abrasion

through

cut

temperature.

The

compound,

On

lifting.

pitting

and/or

adhesion.

chip

from

resistance.

to bare

metal

The

compound,

tested

creep.

or

Cold-temperature

loosen,

elevated

or

resistance.

signs

3.4.10

The

at

as

of

in

4.6.16,

the

shall

coating

the

steel

rusting.

The

more

tested

removal

than

compound,

tested

as

5 percent

of

total

compound,

any point.

tested

the

as

in

4.6.17,

4.6.18,

in

shall

area.

shall

QUALITY ASSURANCE PROVISIONS

4“

4.1

tract

Responsibility for

or

all

purchase

inspection

fied,

in

right

order,

contract

or

suitable

unless

to

4.2

Lot.

perform

4.3

as

is

specified

the

order,

any

of

the

from

of

one

the

Except

may

use

as

his

set

and

offered

to

forth

testing,

for

a

otherwise

the

that

or

conof

speci-

any

other

specification

supplies

lot

delivery

the

requirements

speciGovernment

reserves

in

assure

in

performance

own

of the

inspection

The

Government.

inspections

sampling

batch

specified

for

herein.

supplier

are

deemed

necessary

prescribed

requirements.

purposes

otherwise

responsible

shall

at

one

and

consist

of

time.

Sampling.

4.3.1

filled

tion

For

coating

Unless

supplier

for

the

performance

disapproved

by the

where

such

inspections

services

conform

to

underbody

inspection.

the

requirements

the

facilities

fied

herein,

the

flow

not

Salt-spray

no

not

to

shall

Sampling

containers

level

1 and

verify

compliance

other

requirements

4.3.2

Sampling

ers

shall

be

samples

shall

tainers

laboratory.

and

for

with

not

for

selected

be taken

then

inspection

shall

be

acceptable

sealed,

this

of

selected

quality

filled

specification

involving

tests.

in

A

with

to 2.5

regard

to

each

inspection

From each

of the

lot

two

random

sample

of

MIL-STD-105

at

percent

defective

inspecto

fill,

and

closure,

tests.

From

at random.

and. placed

marked,

containers.

in accordance

level

equal

in

and

separate

forwarded

clean

to

4.2)

(see

containers,

dry

the

metal

designated

or

two

containl-quart

glass

testing

con-

TT-c-520B

4.4

Inspection.

Each sample

filled

container

4.4.1

Inspection

of filled

containers.

4.3.1

shall

be

examined

for

defects

of

construction

of the

specified

in

tainer

and the closure

and for

evidence

of

leakage;

each

filled

container

Any container

shall

also

be weighed

to determine

the amount

of contents.

the

sample

having

one

or

more

jected,

and if

the number

acceptance

number

for

the

represented

by the sample

for

acceptance

provided

forming

products.

4.4.2

or

under

required

fill,

shall

be

conin

re-

of defective

containers

in any sample

exceeds

the

appropriate

sampling

plan

of MIL-STD-105,

the

lot

Rejected

lots

may be resubmitted

shall

be rejected.

the

Testing

Testing.

defects

as

contractor

under

has

this

removed

(or

specification

reworked)

shall

be

all

noncon-

the

following

for

purposes:

(a)

Qualification

(b)

Testing

4.4.2.1

tests

acceptance

Qualification

for

all

4.4.2.2

requi

4.6.17)

for

lots

the

and

shall

be

of

the

the

tests

(or

reworked)

all

3

individual

shall

consist

of

6.3).

(see

lots.

Testing

for

acceptance

of tests

for

the

requirements

specified

storage

stability

(see

3,4.2

and 4.6.9),

cold

temperature

adhesion

(see

4.6.16),

(see

3.4.11

specified

compound

compliance

of the material

with

jected

lots

may be resubmitted

removed

of

testing

section

and

4.6.

in

salt

3.4.10

”18).

The samples selected in accordance with 4.s.2

tests.

to

in

resistance

coating

lots.

Qualification

acceptance

abrasion

subjected

Acceptance

individual

specified

shall

consist

exception

of

(see

3.4.9

and

Lot acceptance

4.5

of

testing.

remnets

Testing

of

individual

3 with

section

spray

resistance

and

testing.

for

by

in

the

4.4.2.2

the

requirements

for

acceptance,

nonconforming

as

Government

of this

provided

material.

outlined

shall

be

in

based

specification.

the contractor

4.6.

upon

Rehas

,

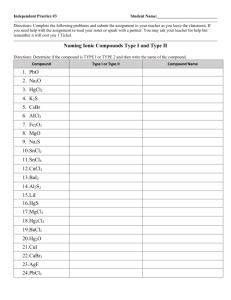

4.5.1 volatile composition (for composition L - see 3.2.2.1 and 4.6.3).

Unless otherwise specified, in lieu of reporting analytical results on the

breakdown of the volatile composition of the coatj.ng compound, the manufacturer may report such results as “calculated” under the condition that he has

carefully described by separate

report,

the character

and detail

of his production methods which in his opinion, guarantee that any suitable analysis

made

include

by

the

Government

a quantitative

each

individual

if

any,

plus

ingredient

substantiating,

will

yield

statement

acceptable

of

identified

data

from

the

results.

formulation

by name,

ingredient

of

Production

the batch

manufacturer,

manufacturer.

and

data

shall

in terms

of

code

number,

TT-c-520B

4.6

Test methods.

—

“4.6.1 Test conditions. The routine and referee testing conditions shall

be in accordance with section 7, Fed. Test Method Std. No. 141, except as

otherwise speciffed herein.

4.6.2

The following tests in Table 11 shall be conducted in accordance

with Fed. Test Method Std. No. 141 and as hereinafter specified.

TABLE Il.

Applicable

method

in Fed.

Test

Method

Std.

No. 141

Tests

Chlorinated

solvents

Aromatic

hydrocarbons

Olefinic

and CYC1Oolefinic

compounds

Ketones

Total

solids

Filler

volume

Weight

per gallon

Flash

point

Consistency

Drying

time:

Set to touch

Practical

hardness

Condition

in container

Storage

stability

Spraying

properties

Sag test

Acid and alkali

resistance

Corrosion

Fire

resistance

Resistance

to flow

Salt

spray

resistance

Cold temperature

adhesion

Abrasion

resistance

4.6.3

I ndex

Test

Method

Solvent

analysis

Paragraph

of

this

specification

giving

fur-

Paragraph

of

this

specification

giving

ther

requirements

references

5132

7356

4.6.3.1

4.6.3.2

3.2.2

3:2.2.1

7356

51j’2

4041

4311

4184

4293

--

4,6.3.1

4.6.3.3

-4.6.4

--

3.2.2.1

4061

-3011

3022

4331

------

6061

--

3.2.2.1

4.6.5

4.6.6

Table

Table

Table

Table

Table

I

I

I

I

I

4.6.7

4.6.7

4.6.8

4.6.9

4.6.10

4.6.11

4.6.12

4.6.13

4.6.14

4.6.15

4.6.16

4.6.17

4.6.18

Table

Table

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

3.4.8

3.4.9

3.4.10

3.4.11

I

I

for composition L.

4.6.3.1 Separationof volatileportion. Separatevolatile portion in

accordancewith method 7355 of Fed. Test Method Std. No’.141. Reserve collected distillatefor the tests for chlorinatedsolvents,aromaticcontent,

toluene,ethyl benzene,olefinicor cyclo-olefiniccompounds,and ketones.

4.6.3.2

Aromatic

content.

Determine

total

aromatic

content

of

volatile

portion

in accordance with procedure A , method 7356 of Fed. Test Method Std.

No. 141. If the total aromatic content is between 8 and 20 percent determine percent of toluene and ethylbenzene in accordance with procedure B,

method 7356 of Fed. Test Method Std. No. 141.

7

TT-C-520B

4.6.3.3 Determination of

according

late

as

substituting

glass

ketone

content.

to method

5172 of Fed.

methyl

isobutyl

ketone.

the

following.

stoppered

tillate

followed

by

v/v

(computed

% ketone,

Add

flask

Erlenmeyer

exactly

25

as

Determine

Test

Method

Omit

first

Std.

total

five

ketone

141 (para

No.

sentences

of

to a 250

15 ml.

of absolute

alcohol

and accurately

pipette

in

ml,

of

methyl

hydroxylamine

isobutyl

1.5

= ~-V7)

of

Fed.

value

of

4.6.5

0.15

Flash

4293 of

method

be

mechanically

to

80

test

and

a

point.

Fed.

nonvolatile

Test

the

rate

to

not

conforming

has

than

a downward

be

nor

2°

)

a bulking

be determined

141,

except

to

value

in

that

direction

a l/16-inch

and allow

to

of

Steel panels.

to QQ-s-698,

65

4.6.8

Condition

method

3011

‘with

3.4.1.

shall

be determined

in

for

unworked

penetration.

of

70

of

the

accordance

dry film

of the compound

on clean

air-dry

in a horizontal

position

of

Storage

Steel

SAE

and

and

panels

1010

a No.

sharp

or

be

1020

Determine

Method

A full

Std.

20

gage

cold

composition,

2 luster

finish.

edges

shall

be

in container.

Fed.

Test

stability.

shall

SAE

The

removed

rolled

with

panels

with

package

condition

141 and observe

container

clf

steel,

a Rockwell

shall

emery

“B”

be clean,

cloth.

in accordance

for

compliance

No.

l-gallon

the

compound

shall

in accordance

for

compliance

3.4.2.

4.6.1o

Spraying

Using

pressure

compound

position,

on the

tank

and gun nozzle

of 80

onto

a 12 by 12 inch

steel

panel

to an average

wet-film

thickness

for

l/4-inch

compliance

Sag test.

4.6.11

4- x 12-inch

steel

panel

in

internal

a standard

with

coating

a

properties.

equipped

the

with

shall

a speed

be stored

for

months

and the

storage

stabi

lity

determined

with

method

3022 of Fed.

Test

Method

Std.

No.

141.

Observe

the

0.12.

conditions.

with

with

100

method

4311

has a bulking

accordance

the stirrer

at

x

0.98 x 0.82

x

raised

throughout

the

duration

more than

3“F.

per minute.

Package

consistency

using

the

procedure

.6.7.1

hardness

of 55 to

free

from corrosion,

4.6.9

in

shall

less

Spray

4.6.7.1

stir

temperature

of

4.6.6

Consistency.

with

ASTM Method

D 21T

steel

4-6”7 panels

w“

under

referee

vehicle

Flash

point

shall

Method

Std.

No.

operated

rpm and

at

the

ml.

dis-

reagent.

Determine

pigment

volume

according

141

assuming

the

volatile

thinner

No.

pigment

volume.

Test

Method

Std.

of

calcu4.3.1

x N x 0.10

1.5

4.6.4

ml.

hydrochloride

ketone)

content

4.3);

paragraph

with

Spray

panel

a vertical

a

mixing

position

heavy

and

material

employing

spray

gun

a maximum

lbs.

per square

inch,

(see

4.6.7.1)

held

in

1/8

of approximately

spray

vertical

inch.

air

the

Exami ne

3.4.3.

l/8-inch

(see

nozzle

4.6.7.1).

and

wet

film

of

Immediately

observe

for

the

compound

after

compliance

evenly

spraying

with

over

a

suspend

3.4.4.

8

1

TT-C-520B

4.6.12

Spray the compound on three

degreased

Acid and alkali

resistance.

to give

a dry-film

thickness

of

steel

panels

(see 4.6 .7.1)

approximately

l/16-inch

(0.45-0.50

lb. per square

ft.).

Air dry 24 hours

and allow

to cool to room temperature.

then bake 16 hours at 170° ~ 5“F.

Seal the panels

around the edges with

a high melting

point

wax by dipping

each edge approximately

1/4 inch in a molten

solution

of the wax and then

immerse one panel

to a depth of 6 inches

for 2“4 hours at 25°C.

(77”F.)

in a

(a) hydrochloric

acid,

10 percent

solution

of each of the following:

On removal each

panel

shall

be

(b) sulfuricacid

and (c) sodium hydroxide.

rinsed

in tap water,

wiped dry with

a soft

rag,

and observed

for compliance

Remove the coating

by solvent

cleaning

(or vapor decreasing)

with

3:4.5.

4- x 12-inch

and examine

4.6.13

each

panel

surface

Corrosion.

of

any

the

copper,

compliance

Completely

QQ-C-576,

convenient

for

size

but

aluminum,

not

less

with

3.4.5.

immerse

three

QQ-A-250/4,

clean

and

polished

strips,

steel

(see

4.6.7.1)

than

by

inches

1/2

inch

3

in

of-the

compound at a temperature

of 800 + 3°C. (176° ~ 5“F.)

ri;se

with

a petroleum

At the end of the test

period

remove,

Examine the panels

for compliance

with

3.4.6.

and dry.

4.6.14

Fire

resistance.

4.6.

paragraph

12 but

hood.

in a shielded

off

and

shut

that

shall

flaming

be

run

4.6.15

continues

to

On removal

position

flow

observe

the

in

3-

by 6-inches

as

in

panels

vertically

with

the air

supply

at

to 2

flame

After

elevated

of the

compound

as in

inch

apart

across

the

a vertical

panels,

one of the

or Tirell)

a container

for 24 hours.

naphtha

solvent,

inches

under the panel

so that

the

1 inch.

Allow

the flame

to remain

observe

the

the flame

is withdrawn,

Test

for compliance

with

3.4.7.

and check

and the results

averaged.

triplicate

Resistance

inch

panel

spaced

1/2

in

in

three

SL5pend

(Bunsen

wax.

burner

the flame

regulated

end of the panel

is in the

the panel

for 20 seconds.

lower

under

time

Prepare

do”not

Place

one

of

an oven

surface

temperatures.

4.6.12

width

of

163° + 3°C.

at

Prepare

a 4Draw parallel

but do” not wax.

of the

surface.

the

coat~ng

(325”

for

Suspend

+ 5“F.)

compl~ance

the

for

with

by

12lines

panel

24

hours.

3.4.8.

4.6.16

Salt-spray

resistance.

Prepare

and wax three

4- by 12-inch

panels

as in paragraph

4.6. 12 and then expose 36o hours to a 5 percent

salt-spray

in

Method

Std.

No.” 141.

On removal:

accordance-with

method 6061 of Fed’. Test

wash

the

panels

any visible

salt

in

warm

running

deposits

spatula

under

the coating

easily

from the

panels

or

film

or in areas

of 4 square

coating

Remove any remaining

observe

the

panel

surface

water

not

more

and

observe

for

compliance

along

one

adheres

of

by

for

or

solvent

compliance

100°F.

with

until

Lifting

over

shall

of the

be cause

(or vapor

cleaning

with

3.4.9.

free

3.4.9.

the wax edges and note

firmly.

inches

than

from

Insert

if

it

a

lifts

coating

as a solid

for

rejection.

decreasing)

and

9

TT-c-520B

4.6.17

(see

Cold

4.6.7.1)

then

be

removed.

removed

(see

figure

than

cold

box

1).

at

slams

and

70

90-degree

the

do

from

slam

test

coating

to

completed.

be

Lay

20

in

handling

time

the

panel

run

in

(

steel

panels

The compound

passes

of

panel

shall

shall

the

coating

by

a 4flat

in

a sandblast

the

the

be

effects

of

during

more than

from

the

20

cold

for

compliance

averaged.

panel

as

a sandblasting

gun

no

elapse

results

12-inch

and

from

then

the

shall

angle

and not

panel

is removed

and

panel

removed

momentarily

Observe

panel

the

is

5 seconds

triplicate

Prepare

the

The

than

at each

specified

the time

the

test

slam

wax.

used

observing

No more

resistance.

not

be

the

apparatus.

angles

degrees.

shall

Abrasion

but

shall

90 degree

80

Test

4.6.18

ject

and

gloves

elapse

the

and inspection

elapse

from

3.4.10.

4.6.12

in

80 and

70,

at

the

shall

placed

the slamming

seconds

shall

box

Asbestos

5 seconds

and

slammed

with

12-inch

edges.

applied

and conditioned

as in paragraph

4.6.12

and the masking

tape

After

conditioning

for

2 hours

at -10”F.,

the

test

panel

shall

be

from

the

cold

box and immediately

placed

in the

slam

test

apparatus

more

the

temperature

adhesion.

Three

12- by

shall

be masked

for

1 inch

along

the

in

hood

conforming

to

the

paragraph

and

sub-

following

dimensions:

Orifice

Length

Inside

of sand

diameter

4.7

with

5.2

hose

of air

hose

shall

traverse

at a distance

of

of the sandblast

the

4-inch

lbs.

(

per

sq.

in.

(

I

May

width

1 inch

from

the

gun,

the

blasted

of

the

surface

area

panel

of

shall

in

the

not

more

coating.

be

examined

for

3.4.11.

of

preparation

the coatinq

of secti~n

PREPARATION

shall

5 of

for

delivery.

The

be inspected

to

this

specification.

packaging,

determine

packing

conformance

to

agencies

mi itary

5 2 through

5.4.3.

shall

and

the

FOR DELl VERY

packing,

and

packaging,

with

MI L-STD-290

and as

Packaging

inch

1-1/4

inches

10 feet

1/4

inch

Cape

20-45

(see

5.2.1

Level

A.

The

friction

top containers,

steel

drums

as specified.

10

hose

90-100

Inspection

The

5.1

accordance

sand

sand

sand

gun

2 seconds

20 passes

markinq

of

requir~ments

5.

of

of

sandblast

compliance

1/2

of

pressure

Type

Mesh

than

After

gun

diameter

Air

The

of

Inside

marking

specified

for

in

be

6.2).

coat

in

ng

shall

5-gallon

be

furnished

lug

cover

in

steel

l-gallon

pails,

multiple

or

in

55-gallon

in

I

.,

TT-C-520B

5.2. 1.1

V,

one-gallon

2,

class

striping

shall

handles

coated

5.2.1.2

3

required.

to

resist

or

gallon

5.2.2

Level

C.

The

commercial

practices.

5.3

cans

shall

conform

to. .type

shall’

side

seam

be supplied

with wire

conform

““

and

corrosion.

handles

Fifty-five

containers

exterior”coating

One-gallon

lug-cover

Wire

top

Plan”B

steel

pails

shall

bails

shall

be

steel

drums

shall

treated

to

to

conform

type

resist

to

11,

class

corrosion.

PPP-D-729,

type

Iv.

or

during

friction

PPP-c-96.

Five-gallon

5.2.1.3

Ill

of

be

PPP-P-704..

of

multiple

round,

-

shipment

and

Packing

(see

5.3.’

packed

in

(Appendix)

coating

shall

be packaged

in accordance

Protection

shall

be such as to prevent

ensure

safe

at

destination.

6.2).

The coating

Level

A.

compliance

with

the

.

delivery

with

suppliers’

deterioration

Five-gallon

pails

packaged

in l-gallon

containers

overseas

shipment

requirements

and

55-gallon

steel

drums

will

of

shall

be

PPP-C+6

require

no

overpacking.

tic

5.3.2

Level

B.

The coating

shall

shipment

requirements

ofppp-C-96

55-gallon

steel

drums will

require

be packed

in

(Appendix].

5.4

with

the domespails

and

no overpacking.

Packing

shall

be in

5.3.3

Level

C.

adequate

to ensure

acceptance

and safe

of ~ransportation

employed.

5.3.4

palletized

accordance

Five-gallon

accordance

delivery

Pallets.

When specified

(see 6.2)

in accordance

with

MIL-STD-147.

with

commercial

by the

shipping

carrier

containers

practice

for

the

shall

mode

abe

Markin~.

5.4.1

Civil

tainers

shall

in 5.4.3.

5.4.2

containers

in 5.4.3.

agencies.

be marked

Military

shall

in

agencies.

be marked

Intermediate

accordance

in

packages

Fed.

with

Intermediate

accordance

and

Std.

exterior

No.

123

packages

and exterior

with

MIL-STD-290

and

shipping

conand as specif

ed

shipping

as specified

11

TT-c-520B

4

5.4.3

each

Additional

can,

pail

marking

and

instructions

for

drum

use

(label

shall

and

requirements).

be

caution

INSTRUCTIONS

Unless

legibly

marked

or

labeled

Wh i e it

the

may

be

usual

wh i ch

y applied

there

are

capac

ty from

pressure

FOR USE:

feet

of

or

two

sets

air

to

ed

of

to

of

tank

to

gun

unit.

Some

with

as

inside

diameter

atomizing

The

material

and

atomizing

air

of

100

pressure

to

fit into bung open

on

spray

should

oil,

The underbody

(40°

to 90”F.)

tar,

coating

and the

compound

applying

the

contamination.

away

coating.

is

per

lbs.

squa~e

the

pump.

gun

be

is

the

applied

rust,

etc.,

material

estimated

from

the

on

same

as

of

inch

the

for

gauges

gun.

15 feet

3/4-inch

control

The

atomizing

OF

pipe

l/4-inch

thread

is

used.

ng

of

d be

a drum

cover

kept

covered

Twenty-five

but

of

air

out-

hose.

for

attachThe

second

the

coatThis

elimpressure

most

come

but not

sealed

feet

of 3/4-

form.

pump the ccating

A 3/8to the gun.

the spray

gun to one of the

two

The pum~s come equipped

with

air

regu-

pressure

on

air

pressure

CAUTION:

12

coupled

The

hose

is used to

is used to connect

outlets

material

of an air-operated

barrel

pump that

delivers

original

55-gallon

containers

to the

gun.

time-consuming

job

of refilling

the

smaller

pumps

diameter

hose

grease,

Keep

the

materia’1

spray

equipment

tank

unit

varyina

in

per minute

no really

supplied

efficient

appl

The

cation.

to the

spray

gun with

approximately

with

either

one

tank

head

is provided

drum covers.

The drum shou

this

would

cause

a vacuum

to

air

atomizing.

The

jobs,

feet

for

the gun with

approximately

having

a spray

head with

lator

which

controls

air

and gauge

which

controls

mud,

small

supply

regulators

and

type

of unit

consists

ing directly

from

the

inates

the bothersome,

inch

inch

An air

15 cubic

is needed

hose.

ai r pressure

on

standard

heavy

One is a pressure

feed hose from tank and a l/4-inch round nozzle

the

tank

a brush

10 to

fluid

the

let

is connected

A special

spray

equipped

air-tight

with

compressor,

the tank

is

thick

coat

(1/8

etc.

, of autofumes,

and to

corrosion.

12 gallons.

3/4-inch

supply

ing

appl

a volume

by a 3- to 5 hp.,

bottom

outlet

of

15

from

in the field

with

two ma n types.

10

and

meta

sDecified,

following

markings:

This

underbody

coating

is intended

for

use in one

inch)

on the

underside

of hoods,

fenders,

floors,

mobiles

to deadel

noise,

to act

as a seal

against

protect

otherwise

with

the

as

pump and with

the air

line

used

with

received

has

been

should

‘shelf

to

a second

regulator

to the

spray

gun for

the

the

pressure

steel

tank

surface

unit.

from

which

removed.

be stored

under

good conditions

life’

(closed

containers)

is

2 years.

FLAt MABLE

flames

Avoid

pro

Provide

snged

adequate

breathing

ventilation

of

vapors

while

or

excessive

skin

‘

TT-C-520B

6.

NOTES

The underbody

coat!ng

covered

by this

specification

Intended”use.

for use in one thick coat (.]/8inch)

on the underside

of hoods,

of automobiles

to deaden noise,

to act as a seal

floors,

etc.

and to protect

the metal

from corrosion.

fumes,

6.1

is

intended

fenders,

against

6.2

Purchasers

Ordering

data.

and procurement

herein

should

documents

and date

number,

and composition

(a)

(b)

Title,

Quantity

(c]

(d)

Alternate

Level

of

inspection

preservation,

(e)

Unit

and

exterior

(f)

The

coating

exercise

specify

should

any

the

desired

options

offered

following:

of this

specification.

required.

if

applicable

packing,

and

(see

4.1).

packaging

required

(see

section

5).

vo 1 ume$

the

(g)

being

unit

Whether

package

covered

by

one

quantities

this

U.S.

gallon

palletization

of

when

applicable.

specification

of

should

231

cubic

container

shipping

be

inches

is

purchased

by

68”F.

at

required

(20”C.).

(see

s.3.4).

I

6.3

With

Qualification.

respect

to

products

requiring

qualification,

awards

will

be made only

for

such products

as have,

prior

been tested

and approved

for

inclusion

for

opening

of bids,

Qualified

Products

List

whether

or not such products

have

listed

by

that

quirement

they

propose

order

that

The

to

offer

may

Aberdeen

Proving

agency

The

procuring

agency.

6.4

The

compound

for

Use,

be

if

thinned

may

raised

to the

Surgeon

Directions

I

may

desired

Federal

be

regarding

departmental

General

of

be

applied

Coating

toxicity

medical

the Army

with

either

5.4.3).

paragraph

It

with

a small

amount

is

of

is

called

to

the

products

for

and

that

Chemical

in

the

the

Laboratory,

to

activity.

should

brush

rethat

for

for

pertaining

authority.

will

act

supplied

mineral

this

qualification

or orders

responsible

information

from

the

time

set

in the applicable

actually

been so

have

contracts

activity

and

obtained

to

tested

awarded

The

21005,

be

suppliers

arrange

Government

to

Maryland

products

questions

procuring

procurement,

the

to

specification.

is the

USA MERDC,

Ground,

of

the

of

urged

eligible

covered

by this

Products

List

Any

are

to

be

products

Qualified

6.3.I

attention

manufacturers

they

qualification

I

date.

and

to

be

as

or

referred

[n the

advisor

power

ready

spirits

by

case

of

to the

spray

the

Army

(see

for

use,

but may

conforming

to

TT-T-291.

6.5

and

Metal

grease

parts

before

of

vehicles

applying

the

should

be

clean

and

dry,

free

from

rust,

oil,

compound.

13

TT-c-520B

6.6 It is bel eved that this specification adequately describes the

to secure

the desired

material,

arid that

normally

characteristics 1ecessary

no samples will be necessary prior to award to determine compliance with

the specification. If, for any particular purpose, samples with bids are

necessary.

they should be specifically asked for in the invitation for bids,

and the particular purpose to be served by the bid sample should be definitely

stated, the specification to apply in all other respects.

6.7 Composition L compound should be specified for use in areas

lations controlling the emission of solvents into the atmosphere.

MILITARY

CUSTODIMTS:

Army - MR

Air Force - 84

with

regu-

‘Preparing activity:

Army - MR

CIVIL AGENCIES COORDINATING ACTIVITY:

User activities:

GSA-FSS

Army - AT

Navy - SA, MC

I

I

Orders for this publication are to be placed with General Services Administration, acting as an agent for the Superintendent of Documents. See section 2 of

this specification to obtain extra copies and other documents referenced herein.

Price 20 cents each.

14

‘IT-C-520

1/$” Guide Plate

F1(3uRE

I.-Slam

—.——.

teuter{for

cold a.dhmima.

_—— ..15

II