IIE!@El

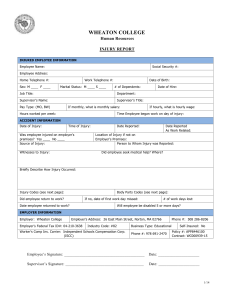

advertisement

IIE!@El

MIL-R-24243C

AMENDMENT 1

30 SEPTEMBER 1994

MILITARY SPECIFICATION

RIVETS, BLIND, NONSTRUCTURAL, RETAINED MANDREL

GENEML SPECIFICATION FOR

This amendment forms apart of MIL-R-24243C, dated 22 June 1994, and is approved for use

by all Departments and Agencies of the Department of Defense.

PAGE 5

In TABLE I under MIL-R-24243/3 SYMBOL D change:

“Mandrel: 1030-1038 Steel

(UNS G103OO-G1O38O)”

custodians:

Arnly-AR

Navy - AS

Air Force -99

Review Activities:

Army - AV, Ml

Air Force -82

National Security Ageney - NS

to read

“Mandrel: 1030-1060 Steel

(UNS G103OO-G1O6OO)”

Preparing Activity:

DLA -IS

(Project No. 5320-0821)

lofl

AMSC N/A

DISTRIBUTION STATEMENT A: Approved for public release: distribution is unlimited.

FSC 5320

IINCH-POUND [

MIL-R-24243C

SUPPLEMENT

1

22 JUNE 1994

MILITARY

RIVETS,

This

supplement

MIL-R-24243/l

MIL-R-24243/2

MIL-R-24243/3

MIL-R-24243/4

MIL-R-24243/5

MIL-R-24243/6

MIL-R-24243/7

MIL-R-24243/8

MIL-R-24243/9

MIL-R-24243/10

SPECIFICATION

BLIND, NONSTRUCTUR?UI, RETAINED

GENERAL SPECIFICATION

FOR

forms

a part

of MIL-R-24243C

dated

MANDREL

21 September

1987.

Rivets, Blind, Nonstructural,

Retained Mandrel; Open-End,

Domed Head; Aluminum Alloy, Carbon Steel, CorrosionResistant Steel.

Rivets, Blind, Nonstructural,

Retained Mandrel; Open-End,

Domed Head; Nickel-Copper

Alloy

Rivets, Blind, Nonstructural,

Retained Mandrel; Open-End,

Large Domed Head; Aluminum Alloy, Carbon Steel

Rivets, Blind, Nonstructural,

Retained Mandrel; Open-End,

100° Countersunk

Head; Aluminum Alloy

Rivets, Blind, Nonstructural,

Retained Mandrel; Open-End,

120° Countersunk

Head; Aluminum Alloy, Carbon Steel,

Nickel-Copper

Alloy

Rivets, Blind, Nonstructural,

Retained Mandrel; Closed-End

Domed Head; Aluminum ~loy

Rivets, Blind, Nonstructural,

Retained Mandrel; Closed-End,

120° Countersunk

Head; Aluminum Alloy

Rivets, Blind, Nonstructural,

Retained Mandrel; Open-End

Snap Head; Aluminum Alloy

Rivets, Blind, Nonstructural,

Retained Mandrel; Open-End,

120° Countersunk

Head; Aluminum Alloy

Rivets, Blind, Nonstructural,

Retained Mandrel; Open-End

Domed Head; Aluminum ~loy

Preparing Activity:

DLA- IS

(Project 5320-0809-11)

AMSC N/A

~.

unlimited.

Approved

for public

release;

FSC 5320

distribution

is

I

INCH-

POUND

I

MIL-R-24243C

L

SUPERSEDING

MIL-R-24243B

21 September

MILITARY

RIVETS , BLIND,

This

SPECIFICATION

NONSTRUCTURAL,

GENERAL

1987

RETAINED

SPECIFICATION

MANDREL

FOR

specification

is approved for use by al 1 Departments

and Agencies of the Department

of Defense.

1. SCOPE

for pull-stem

covers the requirements

1.1

S.CQlX2. This specification

Each

rivet

consists

of

a

body

assembled

on a mandrel

expandable

blind rivets.

available

to

one

side

only.

for fastening where access is

in the head stYlest

Lon,. Rivets shall be furnished

1.2

as specified

in the applicable

and open or closed-end,

material combinations,

specification

sheet (see 3.1) .

2. APPLICABLE

2.1

*

Government

DOCUMENTS

documents.

Unless otherwise

specified,

issues

ons and staQ&@&

2.1.1

of referenced

documents

are those in effect at the time of solicitation.

Information

regarding the latest issue of government

documents and adopted

non-government

documents

can be obtained from the Department

of Defense Index

of Specifications

and standards.

Beneficial

comments

(recommendations,

additions,

deletions)

and any

pertinent data which may be of use in improving this document should

be addressed

to: Defense Industrial Supply Center, 700 Robbins Avenue,

DISC-EPP,

Philadelphia,

PA

19111-5096 by using the self-addressed

Standardization

Document Improvement

Proposal

(DD Form 1426) appearing

at the end of this document or by letter.

----

AMSC

DA

~

N/A

1 of 12

. Approved

for public

FSC

release:

5320

distribution

is unlimited.

MIL-R-24243C

SPECIFICATI’ONS

FEDERAL

Aluminum Allc~y Rod and Wire; For Rivets and Cold

}{eading

Nir:kel-CoppeL- Alloy Bal-, Plate, Rod, Sheet, Strip,

Wire, Forgir~qs al~d Str!lrtural and Special Slldped

Sections

P~ssivatio!] Tr(at.mc’rlLsfo~ Austt>r~itic, lJe~ritic ~llld

Mi~~tensit.i’ I’tjL-LCJSi, n k(:sistant .Steel (Fast~Jnirlg

QQ-A-430

QQ-N-281

QQ-P-35

Devices)

Wilf, Steel, (:arbon, (High (:a~bt~n, Roun(i, fur Me’l]~l\ic~l

Springs (;ci]cLal Purpose)

QQ-W-42F?

MILITARY

MIL-C-5541

MILA-8625

~(>D.p.16~3~

‘See Supplement

1 for

Chemical ~ollvel’sio]l(’oatings @n Aluminum dnci Alumillum

Al 10YS

Anodi<: Contingn,

fol- Aluminum a]ld Aluminum Allvys

P]losplkitc [:oatings, Heavy, Mdng;inese or Zin(: Base (F’01

FeL-I-OUSMetals)

list of associated

specifications)

:;TANDARD.~

MILITARY

MII,-STD 105

MIL-STD-1312-8

MIL-STD-1312-20

Sampling Procedures

and tables f’or Inspection by

Attributes

- Fastener Test Methods-Metl~od 8, ‘Tensile Stl-engt]l

- Fastene~’ Test Metllods-MethtJd 20, Single SIlear

standards,

handbooks,

drawings, public:ltl~>rls,~rlc~

(Copies of specifications,

,ot.herGovel-nmerlL documents

required by contractors

in connection

wit.]]speuii i[,

dr’qu

isit ion fur]ctions s}luuld be obtained from the contla~t ing ;~ctivi(y c~~ ,1:;

diLected by the contracting

activity. )

*

2.2

Other D~lblications. Unless othe~wise

specified,

issues of

~efelerlced documents

are those in effect at tl]e time of solicitation.

Information

regarding

the latest issue of non-government

documents

not

ad(pted by the government

r,an be obtained fl-om L1]C organization

responsible

foI- tt]eir publication.

MIL-R-24243C

●

ASTM

A167

ASTM

A313

ASTM

A493

ASTM

A51O

Stainless and Heat-Resisting

Chromium-Nickel

Steel

plate, Sheet, and Strip

Chromium-Nickel

Stainless and Heat-Resisting

Steel

Spring Wire

Stainless and Heat-Resisting

Steel Wire and Wire Rods

for- Cold Heading and Cold Forging

General Requirements

for Wire Rods and Coarse Round

Wire, Carbon Steel

Stainless and Heat-Resisting

Steel Wire

Electrodeposited

Coatings of Zinc on Iron and Steel

Aluminum and Aluminum-Alloy

Bar, Rod, and Wire

Standard Practice for Commercial

Packaging

ASTM A580

AS’ITIB633

ASTM B211

ASTM D3951

(Application

for copies should be addressed

19103-1187)

Street, Philadelphia,

PA

to the ASTM,

1916 Race

are normally available

(Non-government

standards and other publications

from ~he organizations

which prepare or which distribute

the documents.

These documents also may be available in or through libraries or other

l~lfo~rnational se~-vices. )

In the event of a conflict between the text of

2,3

Order of precedence

this specification

and the references cited herein (except for associated

specification

sheets or MS standards) , the text of

detail specifications,

Nothing in this specification,

this specification

shall take precedence.

laws and regulations

unless a specific

however, shall supersede applicable

exemption has been obtained.

3.

REQUIREMENTS

,.

3.1

shee s.

The individual item requirements

shall be as

SQeclflcation

specified hel-ein and in accordance with the applicable specification

sheets.

In the event of any conflict. between requirements

of this specification

and

the specification

sheets, the latter shall govern.

3.2

,~nd mandrels

as specified

3.2.1

als. The materials used shall be such as to produce bodies

in compliance with the l-equirements of this specifi<:at.ion and

in the applicable

specification

sheet and Table I.

Aluminum

3.2.1.1 Type

aluminum alloys

*

3.2.1.2

applicable

allo~~

1100 (UNS A911OO), 5052 (UNS A95052), and 5056 (UNS A95056)

shall conform to the applicable

requirements

of QQ-A-430.

Type 2024 (UNS A92024) aluminum

requirements

of ASTM B211.

3.2.2

Ca rbon s~e el_ Carbon steel

applicable

specification

sheet.

shall

.-

3

alloy

shall

conform

be of the grade

to the

required

by the

MIL-R-24243C

*

Ca~-bon steel wire. Carbon steel wire employed in the fabrication

3.2.3

of mandrels shall conform to the requirements

of ASTM A51O or QQ-W-428 as

necessary

to install rivet bodies to meet the applicable

strength

~-equirements of Table I.

Nickel-coDD er allov. Nickel-copper

3.2.4

accordance

with Class A of QQ-N-281.

*

TABLE

SYMBOL

I. MATERIAL

MATERIAL

COMBINATION

A

1

(Open-End, Domed Head)

Body :

5056 Al Alloy

(UNS A95056)

Mandrel:

1006-1038 Steel

(UNS G1OO6O-G1O38O)

Body :

5052 Al Alloy

Mandrel:

(UNS A95052)

2024 Al Alloy

(UNS A92024)

B

Body :

D

Mandrel:

1006-1010 Steel

(UNS G1OO6O-G1O1OO

1030-1060 Steel

(UNS G103OO-G1O6OO

Body :

●

F

Mandrel:

Body :

☛

shall

be in

SYMBOLS

COMBINATION

1

MIL-R-24243/l

☛

bodies

Corrosion resistant steel. Corrosion resistant steel employed il]

3.2.5

the manufacture

of bodies and mandrels shall be of the type specified

in the

applicable

specification

sheet and in accordance

with ASTM A493, ASTM A167,

ASTM A580 or ASTM A313 at the supplier’s option.

*

●

alloy

G

Mandrel:

302 CRES (UNS S30200)

302-HQ-CRES

(UNS S30430)

305 CRES (UNS S30500)

305-431 CRES

(UNS S305OO-S431OO)

302 CRES (UNS S30200)

302-HQ-CRES

(UNS S30430)

305 CRES (UNS S30500)

1030-1060 Steel

(UNS G103OO-G1O6OO)

RIVET

DIA

1

MINIMUM

SHEAR

LOAD

LBS

1

.094

.125

.156

.188

.250

90

170

260

380

700

120

220

350

500

920

.094

.125

.156

.188

70

120

190

260

80

150

230

320

.094

.125

.156

.188

.250

130

260

370

540

000

170

310

470

680

1240

.125

420

530

.188

950

1200

.125

420

530

.188

950

1200

I

4

MINIMUM

TENSION

LOAD

LBS

MIL-R-24243C

TABLE

~

I. ~~

- CONTINUED

SYMBOL

MIL-R-24243]2

E

MIL-R-24243/3

A

B

D

MIL-R-24243/

MATERIAL

COMBINATION

(Open-End, Domed Head)

Nickel Copper Alloy

Body :

(UNS N04400)

Mandrel:

1030-1060 Steel

(UNS G103OO-G1O6OO)

(ODen

End, Larqe Domed Head)

.

5056 Al Alloy

Body :

(UNS A95056)

Mandrel:

1006-1038 Steel

(UNS G1OO6O-G1O38O)

5052 Al Alloy

Body :

(UNS A95052)

Mandrel:

2024 Al Alloy

(UNS A92024)

1006-1010 Steel

Body :

(UNs G1OO6O-G1O1OO)

Mandrel:

1030-1038 Steel

(UNS G103OO-G1O38O)

(Open End, 100° Countersunk

Head)

A

Mandrel:

MINIMUM

TENSION

LOAD

LBS

MINIMUM

SHEAR

LOAD

LBS

.

RIVET

DIA

.125

.156

.188

.250

350

550

800

1400

450

700

1000

1850

.125

170

220

.188

380

500

.125

120

150

.188

260

320

260

310

.188

540

680

.125

170

220

.125

–

(UNS A95056)

1006-1038 Steel

(UNS G1OO6O-G1O38O)

.125

B

Mandrel:

MIL-R-24243/5

A

B

D

E

(UNS A95052)

2024 Al Alloy

(UNS A92024)

1

(Open End, 120° Countersunk

Head)

Body :

5056 Al A~~oy

(UNS A95056)

Mandrel: 1006-1038 Steel

(WS G1OO6O-G1O38O)

Body :

5052 Al Alloy

(UIS A95052)

Mandrel: 2024 Al Alloy

(UNS A92024)

Body :

1006-1010 Steel

(UNs G1OO6O-G1O1OO)

Mandrel: 1030-1060 Steel

(UNS G103OO-G1O6OO)

Body :

Nickel-Copper

Alloy

(UNS N04400)

Mandrel: 1030-1060 Steel

(UNS G103OO-G1O6OO)

5

I

.125

.156

.188

170

260

380

220

350

500

.125

120

150

.125

260

310

+

.125

.156

.188

,

350

450

MIL-R-24243C

TABLE

SYMBOL

MIL-R-24243/6

A

c

VIL-R-24243/

MATERIAL

Mandrel:

A

- CONTINUED

(LJNS A95056)

1012-1025

(UNS G1012O-G1O25O)

1045-1075 Steel

(UNs G1045O-G1O75O)

7 (Closed-End,

120° Countersunk

Body :

5056 Al. Alloy

(UNS A95056)

Mandrel:

1012-1025

(UNS G1012O-G1O25O)

1045-1075 Steel

MIL-R-24243/7

A

MINIMUM

SHEAR

LOAD

LBS

RIVET

DIA

COMBINATION

(Closed-End, Domed Head, Hollow

5056 Al. Alloy

Body :

(LJ’NsA95056)

Mandrel: 1012-1025

(LJNS G1012O-G1O25O)

1045-1075 Steel

(UNs G1045O-G1O75O)

11OO Al. Alloy

Body :

(UNS A911OO)

Mandrel: 2024 Al. Alloy

(UNS A92024)

6 (Closed-End, Domed Head, Filled

Body :

5056 Al. Alloy

A

YIL-R-24243/

I. ~

(UNs G1045O-G1O75O)

(Closed-End,

120° Countersunk

Body :

5056 Al. Alloy

(UNS A95056)

Mandrel:

1012-1025

(UNS G1012O-G1O25O)

1045-1075 Steel

(UNs G1045O-G1O75O)

MIL-R-24243/8

(Open-End, Snap Head)

Body :

5052 Al. Alloy

A

(UNS A95052)

Mandrel:

1016-1025 Steel

(UNS G1016O-G1O25O)

MINIMUM

TENSION

LOAD

LBS

Core)

.125

240

280

.156

.188

350

500

480

690

.250

.125

900

100

1100

110

.156

.188

Core)

130

210

160

250

.125

320

280

.156

.188

590

790

480

690

Head, Hol low Core)

.125

240

.156

.188

Head,

350

500

Filled

280

480

690

Core)

.125

320

335

.156

.188

590

790

525

680

.125

165

230

156

:188

255

345

375

525

—-

6

MIL-R-24243C

TABLE

●

I.

*

A

MIL-R-24243/10

*

Surface

MINIMUM

TENSION

LOAD

LBS

Head)

(Open-End, Domed Head)

Body :

5052 Al. Alloy

Mandrel:

MINIMUM

SHEAR

LOAD

LBS

RIVET

DIA

COMBINATION

(Open-End, 120° Countersunk

5052 Al. A~~oy

Body :

(UNS A95052)

Mandrel: 1016-1025 Steel

(UNS G1016O-G1O25O)

A

3.3

- coN’rI~E~

MATERIAL

SYMBOL

MIL-R-24243/9

~

(UNS A95052)

1016-1025 Steel

(UNS G1016O-G1O25O)

.125

155

205

.156

.188

225

350

300

530

.125

165

230

156

:188

255

345

375

525

.

fwsh,

+

3.3.1 AIu minum allov rl vets. Aluminum alloy rivets shall be furnished

or anodically

treated in

chemically

treated in accordance with MIL-c-5541,

No finish is required

at the supplier’s option.

accordance

with MIL-A-8625,

for closed-end

rivets.

*

Carbon steel bodies and mandrels

3.3.2

shall be zinc plated in accordance with ASTM B633 Type II, FE/ZN5, or

phosphate

coated in accordance

with Type Z, Class 2 or 4B of DOD-P-16232,

as

specified

(see 3.1). No finish is required for closed end rivets.

L

alloy bodies

3.3.3 Nickel--coDDer alloy bodies. Nickel-copper

zinc plated in accordance

with ASTM B633 Type II, FE/ZN5.

*

3.3.4 Corrosion

in accordance

with

resistant steel bodies and mandrels

QQ-P-35, Type VI or VII.

3.4

Fastener

QzmzLruction.

applicable

specification

sheet.

assembly

shall

shall

shall

be

be passivated

be as specified

in the

.3.4.1 Rivets shall consist of two parts, a body and a mandrel assembled

In combination

as specified on the applicable

specification

sheet (see 6.2)

3.4,2 Rivet bodies

action of the mandrel

3.4.3

sheet .

Dimensions

shall be capable of being expanded mechanically

by the

when pulled into the rivet body as shown on Figure 1

shall

be as specified

in the applicable

specification

3.4.4 ~trenqth,

Single shear and tension load capabilities

~-ivets shall not be less than specified in Table I.

of installed

3.5

Rivets shall

M?xlmansk@.

inj~lrious seams and other injurious

free

be of uniform

defects.

quality

and

from

.—

MIL-R-24243C

4.

QIJALITY ASSURANCE

PR’(YJISIONS

Respor]sibilitv for inspection. Unless otherwise specified

in tl~e

4.1

is responsible

for the

c:ontrac~ or pul-~:}laseol-der, the contractor

Except as

perform~nce

of all inspection

requil-ements as specified herein.

may use his own

ottlr,

]-wist,specified

in the cor~tr~(<t or order, the contractor

01

any other facilities

suitable for El]e performance

of the inspection

The

unless disapproved

by the Government.

Iequirernents specified hc’l”eirl,

set fo~-tllin

Guvclnment

reserves the right to perfor’rniiny of the inspections

illspertions are deemed necessary

to as:;u~’e

tile spccific~t.icn whe~-cmS\]f:ll

%~]~,plit:sand services confu~ln to p~’escribe(i requirements.

All

itelns must meet all

4.1.1 Resl~onsibilitv foK romnliancc.

Ir{?quil-emerlts

of ser-tions 3 and 5. Tile inspection set forth in this

overall inspection

:;p~=ci

f i~~t ion shall ber[~mt> ~ part of the contractor’s

any inspectioll requirements

i[l

system CL qudlity progL-arn, The dbserrre of

Lllc ~;F)(>C:ifiration

~;l]allnot relieve the contractor

of the ~-esponsibility of

assu~il]g that all supplies submitted (.c)the Government

for acceptance

comply

will} dl 1 l-eq(]irel[[ent

:; of th~ contrac~

Sanlpling in quality conformance

does

riot ,iutt].lize submission

of known defective material,

either indicated or

Clf’tl)dl

,

1101

does it cormnit the Govt~I]meI~t t.c accept~nce

of defective

Ill<]t[,lial

(h]alitv c’[)rrl(orrr

4.2

~flr~ inspert ior). ~)llalityconformance

irl Table 11.

sl’!illtt= is spcrificd

TABLE

II. QIJAI,ITY CONFORMANCE

INSPECTION

REQUIREMENT

PARAGRAPH

3.4.3

3.3

3.3.4

3.4.4

3.4.4

Dilnensiorls

Protective

Su~-face

Sul-face Tredtrrlent

Single She~r

Tel]sion

inspec’tiorrs

INSPECTION

EXAMINATION

OR

TEST PARAGRAPH

4.2.3

4.3.3

4.3.4

4.3.1.1

4.3.1.2

4..?.1 Inspection

lot. An inspection

lot shall consist of rivet body and

[[idr)dlelasselnblies of tile :;dlne mdterial,

finis]] and nominal size produced by

rllc same n[~n~]f,lcture~und(’~-essentially

the same conditions

and submitted

fo~- acceptance

at one time.

4.2.2 Rejected lots. If an inspection

lot is ~-ejected, the

rewolk it to correct the defects, OF screen Out

the defective

resubmit for inspection.

Resubmitted

lots shall be inspected

tiqhtened

inspection.

Such lots shall be separated

from new

be rlearly identified as ~einspected

lots.

*

4.2.3 SamDlinq fOr vis~lal & dimensional

body an.i mdn~lL-el assemblies

sh~ll be takrn

MIL-ST})-1O5 ds follows:

14aju~ - Inspection

Level S3

Mlrrol- Inspr~;tiun I,evel S2

Acceptance

. 200

Rejertion

. 1

8

contractor

may

units, and

using

lots, and shall

examination,

A random sample of

fl-om eacl] lot in accordance

with

MIL-R-24243C

*

4.2.4

strength and tension loads

Inspection Level S-2.

shall

Sampling for shear

with MIL-STD-105

at

and t~

be in accordance

L

ectlo~

4.3

*

*

Sample

assemblies

selected

4.3.1

with 4.2.4

compliance

shall be tested as specified in 4.3.1.1

with Table I of this specification.

4.3.1.1

accordance

.Sinule shear la

with Test Method

The shear

test

shall

20 of MIL-STD-1312,

in accordance

and 4.3.1.2

to assure

be performed

in

or equivalent.

The tension test shall be performed

10A

4.3.1.2 Tens ti

with Test Method 8 of MIL-STD-1312,

or equivalent.

in accordance

ination. Samples of rivets shall be

4.3.2 Visual and dimeni i

Examination

shall

specification.

examined to verify conformance

with this

be conducted

in accordance

with Table III.

TABLE

ON OF DEl?KllS

111.

L

None

Critical

Major

*

201

202

203

204

205

of rivet

body

(3.5)

Diameter of rivet head (3.4)

Length of rivet body

Thickness of rivet body head (3.4)

Diameter of mandrel

(3.4)

Radius under head (where applicable)

(3.4)

Length of mandrel

(3.4)

Angle of rivet head (where

applicable)

(3.4)

Protective

finish and surface

treatment missing or incomplete

(as applicable)

(3.3)

Workmanship

(3.5)

206

207

208

209

3 / ~u,~,tt,=~~~=~

Pnmm’-.o<o<

.1

Al

defined

Diameter

101

Minor

*

INSPECTI

ON

METHOD

DEFECT

CATEGORY

T“c.,c,mt<fin

L.,apcLLAuAL

CIE 1/

CIE

CIE

CIE

CIE

CIE

CIE

CIE

Visual

Visual

U,-.,,;-mA-t

lLyuLpttkcA.L

4.3.3 ~ective

finish.

Samples of aluminum alloy, carbon steel and

nickel-copper

bodies and/or mandrels, shall be inspected for adequacy of

protective

finish in accordance with applicable

specification

of 3.3.

4.3.4 surface tr~tmentSamples of corrosion resistant

mand~-els , shall be passivated as specified in 3 3 .4 .

L

1

9

steel

bodies

and

MIL-R-24243C

I. ~ .L PI&I~L-iddIELEC~

Materials

inspections shall consist of

certification

supported by verifying data that the materials used in fabricating

tile bed>, ax]d mandrel assemblies

are in accordance with the requirements

of 3 2,

prior to such fabrication,

5. PACKAGING

*

The requirements

5.1

Packaaing reauirement~

accordance

with ASTM D3951 (see 6.2) .

for packaging

shall

be in

6. NOTES

Rivets required by this specification

are

6.1

late nded U.e

as shown on Figure

~-apid and permanent

fastenings substantially

setting tools may be manually or power operated.

intended fo~

Rivet

1.

6.1,1 In general, these rivets are used to fasten metal to metal, wood to

Typical nonstructural

applications

are as follows:

metal , and plastics to metal.

Attachments

such as for handles, hinges, brackets and clips; lockers such as for

food and clothes; bins, metal furniture, racks, shelves; assembly of tube sockets

boxes,

and terminal boards; fastening conduit clips, raceways, electrical

distribution

panels; fastening siqns, bulletin boards, and safety guards around

equipment ; installing

light fixture mounting brackets; repair of light sheet

metal equipment

6.1.2 Clo:;ed-end rivets are intended for application

(under the most optimum

conditions,

I.e., proper hole size, grip length and over coated with sealant,

etc. ) where gas, oil, water or air tightness is required.

6.1.3 These rivets are not intended

rivets, see MIL-STD-1515,

~-equirements

6.2

Drd erinq

6.2.1

Acquisition

(a)

*

+

Fol- aerospace

usage.

data,

Title,

requirements

number,

specification

*

for aerospace

2 and 3.

(b)

Applicable

(c)

Level

should

and date

specify

the following:

of this

specificatj.on

sheet

(see 3.1) part

and

specification

(degree)

of protection

in accordance

numbe~-.

with

6.2.2 ~]isition

of xlvet.. manufactured

wrlor to isifi~v~

Unless otherwise specified, Revision C is applicable

to rivets

(DATE) .

6.3

Subject

term

applicable

sheet,

(Key Word)

listing.

Blind Fastener

Rivet, Blind

Rivet, Blind, Nonstructural

.

10

ASTM

D3951.

manufactured

~

after

MIL-R-24243C

●

The margins of this specification

are

fr~

6.4

marked with asterisks to indicate where changes

(additions, modifications,

This was done as

deletions)

from the previous issue were made.

corrections,

a convenience

only and the Government assumes no liability whatsoever

for

Bidders and contractors

are cautioned

any inaccuracies

in these notations.

of this document based on the entire content

to evaluate

the requirements

to the last previous

irrespective

of the marginal notations and relationship

issue .

rmu[[)HIA7

SNAP H[M

COUNl[R$llhK

HIAD

●

Ii

pw#-

L

(:10S! 1) [ ND WIT,

lowCOR[

I{():

couNlr

RSUNKHMO

dir

W

\

FIGURE

1.

sRm

11

.— -

MIL-R-24243C

—

Custodians :

Army - AR

Navy - AS

Air Force

Preparing

DLA-IS

Activity:

(Project

5320-0809)

- 99

Review Activities:

Army - AV, MI

Air Force - 82

User Activities:

National Security

Agency

-NS

—

12