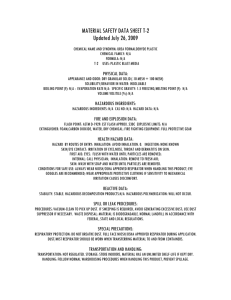

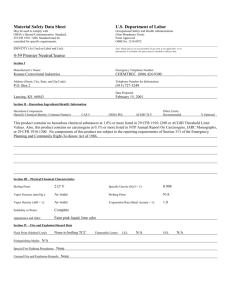

Health and Safety

advertisement