15/11/2012 Lean Deployment in a Medical Device Plant Ivan Hanley

advertisement

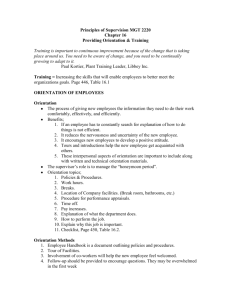

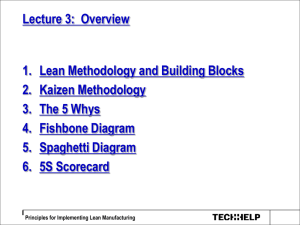

15/11/2012 Lean Deployment in a Medical Device Plant Lean Deployment in a Medical Device Plant Ivan Hanley 27-Sep-2012. Vision Care Ireland Brief Overview Vision: To bring healthy vision to everyone, everywhere, everyday. Mission: to lead the world in innovation, growth, profitability and customer satisfaction. Vision Care Ireland Brief Overview • Manufacturing Operations: Jacksonville Florida Limerick, Ireland. • In Operation since 1996. • Manufacture Class II and III medical devices. (contact lenses) • Plant operates 24/7, ships 5.5 days/week. • 4 Value Streams established. 1 15/11/2012 What is Lean "Lean," is a production practice that considers the expenditure of resources for any goal other than the creation of value for the end customer to be wasteful, and thus a target for elimination. Working from the perspective of the customer who consumes a product or service, "value" is defined as any action or process that a customer would be willing to pay for. (from Wikipedia) Elements of Lean Elements to be covered today • OGSMs • True North • Value Stream Alignment • Identifying Waste • Visual Management and Mistake Proofing • Standardised Problem Solving • Standard Work • TWI OGSMs (Objectives, Goals, Strategies and Measures) OGSM is a an excellent way of aligning an organization. Originally developed in Japan in the 1950s by the major car manufacturers. Used by some companies as a strategic planning tool. Goals and objectives cascade down the company. 2 15/11/2012 True North “Guiding” the organisation towards its ultimate goals. Follow the ‘c3e’ model Clarity – have SMART goals Challenge – able to motivate Commitment – bacon vs. egg Execution – including regular monitoring Value Stream Alignment • 4 Value Streams established in Vision Care • Operations, Engineering & Quality aligned to Value Stream. • Common OGSMs and KPIs across Value Stream. • One owner with full responsibility and accountability. • Personnel and Support services located within the Value Stream. Identifying Waste Identifying Waste Waste is anything that does not add direct value to the end service or product from the customer’s perspective. Identified by: • VSM • Waste Walks • Gemba Walks • Automated OEE reports 3 15/11/2012 Kaizen Kaizen = continuous improvement Kaizen is based on making little changes on a regular basis: always improving productivity, safety and effectiveness while reducing waste. Critical to the success of a Kaizen are 1) Defined roles and responsibilities 2) Agreed problem statement with current and future state defined. Visual Management & Mistake Proofing Visual Display: information is displayed and clearly visible to EVERYONE Visual Management is a Visual Display that clearly identifies ‘abnormalities’ and triggers a reaction to correct it. Mistake Proofing (Poka Yoke) is to design the process so that mistakes can be detected and corrected immediately. 100% Inspection Test Why not just inspect / test out defects? No test or inspection is 100 percent effective in finding defects within a product. If you doubt this, then try this experiment: – Count the number of times the letter “e” appears on this page. – Once you have counted the number of times that “e” has been used, write your answer on a sheet of paper. – Your answers will be collected, and the instructor will tally the number for the class and will discuss the results. 4 15/11/2012 100% Insp52ction T53st Why not just insp51ct / t50st out d49f48cts? No t47st or insp46ction is 100 p45rc44nt 43ff42ctiv41 in finding d40f39cts within a product. If you doubt this, th38n try this 37xp36rim35nt: – Count th34 numb33r of tim32s th31 l30tt29r “28” app27ars on this pag26. – Onc25 you hav24 count23d th22 numb21r of tim20s that “19” has b18 17n us16d, writ15 your answ14r on a sh13 12t of pap11r. – Your answ10rs will b9 coll8ct7d, and th6 instructor will tally th5 numb4r for th3 class and will discuss th2 r1sults. Standard Work The best practice to maintain consistent and repeatable level of quality in their production processes. By documenting the current best practice, standardized work forms the baseline for kaizen or continuous improvement. As the standard is improved, the new standard becomes the baseline for further improvements, and so on. Improving standardized work is a never-ending process. Training Within Industry (TWI) Training Within Industry (TWI) is a job instruction training methodology to help a trainer effectively transfer knowledge to a trainee. Structured 1 on 1 training 1) The trainer prepares a trainee with an overview of the job, its purpose and the desired results. 2) The trainer demonstrates the task to the trainee. (3 times, with different focus each time) 3) The trainee then demonstrates the task back to the trainer. (4 times, with different focus each time until competence in the task is demonstrated.) 4) The trainer follows up by providing feedback and help if required. 5 15/11/2012 Standardised Problem Solving Adopt Specific standardised problem solving techniques that can solve your problems. • Lean DMAIIC. • Shainin Approach. • A3 or ‘8D’ – used for every Kaizen. Collaboration There are a number of ways we collaborate in Vision Care Ireland: • Campus Ireland. Process Excellence Lean Alignment with Depuy, Janssen Pharma, Janssen Bio and Vision Care. • Jacksonville and Ireland. Mirrored Roles and Responsibilities with Joint OGSMs and deliverables. • Johnson & Johnson MD&D. Share Best Practices / Lead new initiatives. 6