JBED Journal of Building Enclosure Design

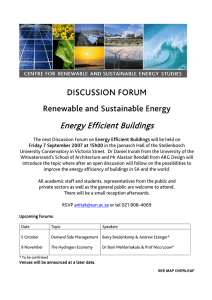

advertisement