Carbon nanomaterials as metal-free catalysts in next generation fuel cells SHORT COMMUNICATION

advertisement

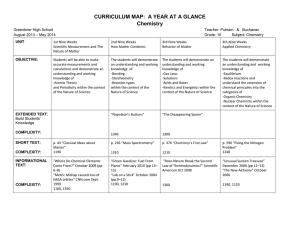

Nano Energy (2012) 1, 514–517 Available online at www.sciencedirect.com journal homepage: www.elsevier.com/locate/nanoenergy SHORT COMMUNICATION Carbon nanomaterials as metal-free catalysts in next generation fuel cells Mei Zhang, Liming Dain Case School of Engineering, Case Western Reserve University, 10900 Euclid Avenue, Cleveland, OH 44106, USA Received 5 January 2012; received in revised form 8 February 2012; accepted 24 February 2012 Available online 9 March 2012 KEYWORDS Abstract Oxygen reduction reaction; Metal-free catalysts; Fuel cells; Carbon nanomaterials; Doping; Charge transfer A new class of carbon nanomaterials has been discovered as metal-free catalysts to dramatically reduce the cost and increase the efficiency of fuel cells. This article highlights recent progresses in this emerging research area. & 2012 Published by Elsevier Ltd. The rapid increase in the global energy consumption and the environmental impact of traditional energy resources pose serious challenges to human health, energy security, and environmental protection. One promising solution, providing clean and sustainable power, is fuel cells. Instead of burning fuel to create heat, fuel cells convert chemical energy directly into electricity [1]. This energy conversion technology currently receives intensive research and development focus because of its high energy conversion efficiency (typically, 40–60% or up to 85% efficiency if waste heat is captured for use), virtually no pollution, and potential large-scale applications [2]. By pumping, for example, hydrogen gas onto the anode, hydrogen is split into its constituent electrons and protons. The protons diffuse through the cell toward the cathode while the electrons n Corresponding author. Tel.: +1 216 368 4176; fax: +1 216 368 4202. E-mail address: liming.dai@case.edu (L. Dai). 2211-2855/$ - see front matter & 2012 Published by Elsevier Ltd. doi:10.1016/j.nanoen.2012.02.008 flow out of the anode to provide electrical power (Fig. 1a). Electrons and protons both end up at the cathode to combine with reduced oxygen to form water. While the very facile H2 oxidation kinetics greatly reduces the amount of catalyst (e.g., platinum) at the anode, the slow oxygen reduction reaction (ORR) on the cathode is a key step to limit the energy conversion efficiency of a fuel cell and requires a substantial amount of platinum catalyst (representing at least a quarter of the fuel cell cost). Although platinum nanoparticles have long been regarded as the best catalyst for the ORR, the Pt-based electrode suffers multiple drawbacks, including its time-dependent drift, methanol crossover, and CO deactivation [2]. This, together with the high cost of platinum and its scarcity, has made these catalysts the primary barrier to mass market fuel cells for commercial applications. Thus, the large-scale practical application of fuel cells has not been realized, though alkaline fuel cells with platinum as an ORR electrocatalyst were developed for the Apollo lunar mission in the 1960s [1]. Carbon nanomaterials as metal-free catalysts 515 Figure 1 (a) Schematic representation of the working principle for a fuel cell. Adapted from Ref. [6]. (b) (left) The calculated charge density distribution and (right) schematic representations of possible adsorption modes of an oxygen molecule. Adapted from Ref. [5]. (c) Electronegativity of elements increases along the Y-axis, leading to electron transfer from carbon atom, C, to nitrogen atom, N, along the gradient. Adapted from Ref. [7]. Even though the amount of platinum needed for the desired catalytic effect could be reduced using Pt alloys [3,4], most non-noble metal catalysts still remain too low in efficiency when compared to Pt or too expensive as commercial mass production would still require large amounts of platinum. The large-scale practical application of fuel cells will be difficult to realize if the expensive platinum-based electrocatalysts for ORR cannot be replaced by other efficient, low cost, and stable electrodes. Along with the intensive research efforts in reducing or replacing Pt-based electrode in fuel cells, a new class of carbon nanomaterials has been discovered, which, as alternative ORR catalysts, could dramatically reduce the cost and increase the efficiency of fuel cells [5]. For example, our research has found that vertically-aligned nitrogen-doped carbon nanotube (VA-NCNT) arrays can act as a metal-free electrode to catalyze an ORR process free from CO ‘‘poisoning’’ with a 3-times higher electrocatalytic activity, much smaller crossover effect, and better longterm operational stability than that of the commercial platinum-based electrode (C2-20, 20% platinum on Vulcan XC-72R; E-TEK) in alkaline fuel cells [5]. Based on the experimental observations and quantum mechanics calculations by B3LYP hybrid density functional theory [5], we attributed the improved catalytic performance to the electron-accepting ability of the nitrogen atoms, which creates net positive charge on adjacent carbon atoms in the nanotube carbon plane of VA-NCNTs (Fig. 1b) to readily attract electrons from the anode for facilitating the ORR. The nitrogen-induced charge delocalization can also change the chemisorption mode of O2 from the usual end-on adsorption (Pauling model) at the nitrogenfree CNT (CCNT) surface (top right, Fig. 1b) to a side-on adsorption (Yeager model) onto the NCNT electrode (bottom right, Fig. 1b). The N-induced charge-transfer from adjacent carbon atoms could lower the ORR potential while the parallel diatomic adsorption could effectively weaken the O–O bonding, facilitating ORR at the VA-NCNT electrode [5]. Uncovering this new ORR mechanism in the nitrogen-doped carbon nanotube electrode is significant as that the same principle could be applied to the development of various other metal-free efficient ORR catalysts for fuel cell applications. Although it is still a challenge to determine the exact locations of nitrogen atoms in the carbon nanotube structures and chemical nature of the catalytic sites, recent research activities carried out in many laboratories, including our own one, have not only confirmed the above findings but also further proved that the doping-induced charge transfer has large impact on the design/development of new metal-free catalytic materials for fuel cell and many other applications [8]. For instance, Yang et al., [9] have recently extended the doping atoms to include boron with a lower electronegativity than that of carbon (Fig. 1c). These 516 authors found that the doping-induced charge redistribution, regardless whether the dopants have a higher (as N) or lower (as B) electronegativity than that of carbon (Fig. 1c), could create charged sites (C + or B + ) favorable for O2 adsorption to facilitate the ORR process. This work suggests further exploration of the metal-free electrocatalysts based on carbon nanotubes doped by atoms (other than N and B) with electronegativities different from that of carbon atom (Fig. 1c). By extension, we have successfully prepared vertically-aligned BCN (VA-BCN) nanotubes containing both nitrogen and boron heteroatoms. Due to a synergetic effect arising from the co-doping of carbon nanotubes with boron and nitrogen, the resultant VA-BCN nanotubes were demonstrated to show a higher electrocatalytic activity for ORR in alkaline medium than VA-CNTs doped with either boron or nitrogen only [10]. The observed superior ORR performance with a good methanol and CO tolerance and excellent durability for the VA-BCN nanotube electrode than the commercial Pt/C electrode opens up avenues for the development of novel efficient metal-free ORR catalysts by co-doping carbon nanotubes with more than one heteroatom of electronegativities different from that of carbon atom (Fig. 1c). As a building block for carbon nanotubes, graphene is an alternative candidate for potential uses as the metal-free ORR catalyst. Indeed, N-doped graphene (N-graphene) films produced by chemical vapor deposition (CVD) in the presence of ammonia have recently been demonstrated to show a superb ORR performance similar to that of VA-NCNTs with the same nitrogen content in alkaline medium [11]. The ease with which graphene materials and their N-doped derivatives can be produced by various low-cost, large-scale methods, ranging from the CVD to solution exfoliation of graphite [12], suggests considerable room for cost effective preparation of metal-free efficient graphene-based catalysts for oxygen reduction. In addition, Liu et al. [13] have reported the ORR electrocatalytic performance better than platinum for nitrogen-doped ordered mesoporous graphitic arrays (NOMGAs) prepared by a metalfree nanocasting technology using a nitrogen-containing aromatic dyestuff, N,N0 -bis(2,6-diisopropyphenyl)-3,4,9,10perylenetetracarboxylic diimide (PDI), as the carbon precursor. Owing to the metal-free preparation procedure, the reported electrocatalytic activity can be attributed exclusively to the incorporation of nitrogen in PDI-NOMGAs. In a somewhat related, but independent study, Liu et al. [14] have demonstrated phosphorus-doped graphite layers with high electrocatalytic activity for ORR in an alkaline medium. Metal-free N-doped MWCNTs or ordered mesoporous carbons (OMCS) have also been produced through carbonization of a MWCNTsupported polyaniline (PANI) coating [15] or via NH3 activation [16]. These metal-free N-doped nanocarbons have also been demonstrated to exhibit high ORR activities even in acidic electrolytes. Good ORR activities in the acidic media have also been observed for NCNTs produced by both metal catalyzed and metal-free nanotube growth processes [17–19]. However, the catalytic performance of these reported N-doped carbon nanomaterials in acidic medium still needs to be further improved to meet the requirement for practical applications. In addition to the intramolecular charge-transfer that impart ORR electrocatalytic activities to heteroatom-doped carbon nanotubes, graphene and graphite described above, we have recently demonstrated that certain polyelectrolyte (e.g., poly(diallyldimethylammonium chloride)) adsorbed M. Zhang, L. Dai pure carbon CNTs or graphene, either in an aligned or nonaligned form, could also act as metal-free electrocatalysts for ORR through the intermolecular charge-transfer from the all-carbon CNTs or graphene to the adsorbed PDDA [20,21]. It is notable that the PDDA adsorbed verticallyaligned CNT electrode possesses remarkable electrocatalytic properties for ORR; similar to that of commercially available Pt/C electrode. These results clearly indicate that the important role of intermolecular charge-transfer to ORR can be applied to carbon nanomaterials in general for the development of various other metal-free efficient ORR catalysts for fuel cell applications, even new catalytic materials for applications beyond fuel cells (e.g., metal–air batteries, electrochemical biosensors). However, further study on the catalytic mechanism and kinetics is still needed in order to design and develop functionalized carbon-based catalysts with a desirable activity and durability. The long-term performance evaluation of these nanocarbon catalysts in actual fuel cells should also be performed. We firmly believe that heteroatom-doping of carbon nanomaterials (e.g., nanotube, graphene, mesoporous carbon) to induce the intramolecular charge transfer has been shown to be a promising approach to the development of metal-free, carbon-based catalysts with even a higher electrocatalytic activity and better long-term operation stability than that of commercially available platinum-based electrodes for oxygen reduction in fuel cells. Furthermore, intermolecular chargetransfer has also been demonstrated to impart ORR activities to all-carbon carbon nanomaterials for fuel cell applications, even new catalytic materials for applications beyond fuel cells. Although the ORR catalytic performance of N-doped carbon nanomaterials in acidic media is still relatively poor with respect to that in alkaline electrolytes, judicious application of the intramolecular (intermolecular) chargetransfer processes with various dopant atoms of different electronegativities (charged absorption moieties) to different carbon nanomaterials has opened up the rich field of metalfree ORR electrocatalysts with vast opportunities. Further development in this exciting field will surely revolutionize the way in which future energy systems are developed, and should result in a better fuel economy, a decrease in harmful emissions, and a reduced reliance on petroleum sources. Our work was supported financially by the NSF (CMMI1000768, CMMI-1047655, IIP-0924197, DMR-1106160), the AFOSR (FA2386-10-1–4071, FA 9550-10-1–0546, FA9550-09-10331, FA9550-12-1-0037), the DOD-Army (W911NF-11-10209) and the DOE (DE-SC0003736). References [1] /http://americanhistory.si.edu/fuelcells/alk/alk3.htmS. [2] S. Basu, Recent Trends in Fuel Cell Science and Technology, Anamaya Publishers, New Delhi, 2007. [3] H.Y. Bing, H.S. Liu, L. Zhang, D. Ghosh, J.J. Zhang, Chemical Society Reviews 39 (2010) 2184–2202. [4] D.J. Zhao, G.P. Yin, J. Wei, Progress in Chemistry 21 (2009) 2753–2759. [5] K. Gong, F. Du, Z. Xia, M. Dustock, L. Dai, Science 323 (2009) 760–764. [6] /http://www.fuelcells.org/basics/how.htmlS. [7] /http://users.rcn.com/jkimball.ma.ultranet/BiologyPages/ E/Electronegativity.htmlS. Carbon nanomaterials as metal-free catalysts [8] D. Yu, E. Nagelli, F. Du, L. Dai, The Journal of Physical Chemistry Letters 1 (2010) 2165–2173. [9] L. Yang, S. Jiang, Y. Zhao, L. Zhu, S. Chen, X. Wang, W. Qiang, J. Ma, Y. Ma, Z. Hu, Angewandte Chemie International Edition 50 (2011) 7132–7135. [10] S. Wang, E. Iyyamperumal, A. Roy, Y. Xue, D. Yu, L. Dai, Angewandte Chemie International Edition 50 (2011) 11756–11760. [11] L. Qu, Y. Liu, J.B. Baek, L. Dai, ACS Nano 4 (2010) 1321–1326. [12] I.-Y. Jeon, S.-Y. Bae, D. Yu, D.W. Chang, L. Dai, J.-B. Baek, Chemistry of Materials 23 (2011) 3987–3992 (and references cited therein). [13] R. Liu, D. Wu, X. Feng, K. Mullen, Angewandte Chemie International Edition 122 (2010) 2619–2623. [14] Z.-W. Liu, F. Peng, H.-J. Wang, H. Yu, W.-X. Zheng, J. Yang, Angewandte Chemie International Edition 50 (2011) 3257–3261. [15] C. Jin, T.C. Nagaiah, W. Xia, B. Spliethoff, S. Wang, M. Bron, W. Schuhmann, M. Muhler, Nanoscale 2 (2010) 981–987. [16] X. Wang, J.S. Lee, Q. Zhu, J. Liu, Y. Wang, S. Dai, Chemistry of Materials 22 (2010) 2178–2180. [17] W. Xiong, F. Du, Y. Liu, A. Perez Jr., M. Supp, T.S. Ramakrishnan, L. Dai, L. Jiang, Journal of the American Chemical Society 132 (2010) 15839–15841. [18] D. Yu, Q. Zhang, L. Dai, Journal of the American Chemical Society 132 (2010) 15127–15129. [19] S. Kundu, T.C. Nagaiah, W. Xia, Y. Wang, S.V. Dommele, J.H. Bitter, M. Santa, G. Grundmeier, M. Bron, W. Schuhmann, Journal of Physical Chemistry C 113 (2009) 14302–14310. [20] S. Wang, D. Yu, L. Dai, Journal of the American Chemical Society 133 (2011) (5182-5182). [21] S. Wang, D. Yu, L. Dai, D.W. Chang, J.-B. Baek, ACS Nano 5 (2011) 6202–6209. 517 Mei Zhang is a Research Assistant Professor in the Department of Biomedical Engineering at Case Western Reserve University (CWRU). She also holds a joint appointment in University Hospitals-Case Comprehensive Cancer Center. Zhang’s expertise ranges across the synthesis and characterization of polymers and nanomaterials, nanotechnology, tumor immunology, and immunotherapy in the treatment of cancer. Her primary research interest is to apply polymer materials to the design and development of novel nanoparticle systems for multifunctional applications, including gene drug delivery, biomedical imaging, and bio-energy systems (e.g., biofuel cells). Liming Dai is the Kent Hale Smith Professor in the Department of Macromolecular Science and Engineering at Case Western Reserve University (CWRU). He is also the director of the Center of Advanced Science and Engineering for Carbon (CASE4Carbon). Before joining the CWRU, he was an associate professor of polymer engineering at the University of Akron and the Wright Brothers Institute Endowed Chair Professor of Nanomaterials at the University of Dayton. Dr. Dai’s expertise lies across the synthesis, chemical modification and device fabrication of conjugated polymers and carbon nanomaterials for energyrelated and biomedical applications.