Document 12030862

advertisement

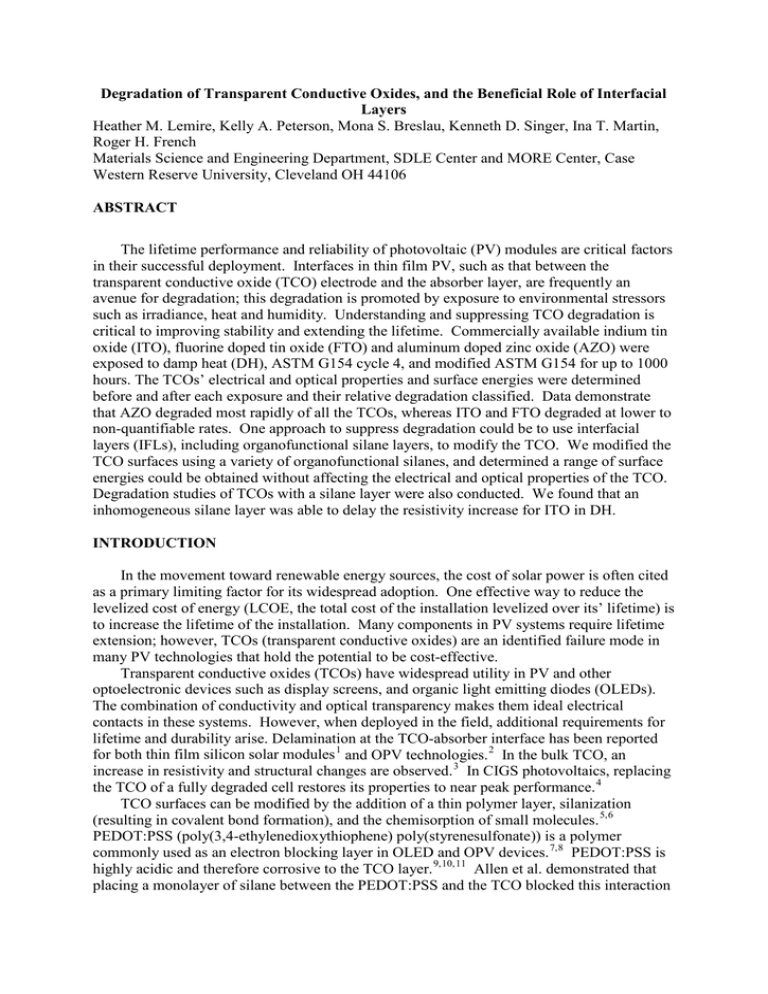

Degradation of Transparent Conductive Oxides, and the Beneficial Role of Interfacial Layers Heather M. Lemire, Kelly A. Peterson, Mona S. Breslau, Kenneth D. Singer, Ina T. Martin, Roger H. French Materials Science and Engineering Department, SDLE Center and MORE Center, Case Western Reserve University, Cleveland OH 44106 ABSTRACT The lifetime performance and reliability of photovoltaic (PV) modules are critical factors in their successful deployment. Interfaces in thin film PV, such as that between the transparent conductive oxide (TCO) electrode and the absorber layer, are frequently an avenue for degradation; this degradation is promoted by exposure to environmental stressors such as irradiance, heat and humidity. Understanding and suppressing TCO degradation is critical to improving stability and extending the lifetime. Commercially available indium tin oxide (ITO), fluorine doped tin oxide (FTO) and aluminum doped zinc oxide (AZO) were exposed to damp heat (DH), ASTM G154 cycle 4, and modified ASTM G154 for up to 1000 hours. The TCOs’ electrical and optical properties and surface energies were determined before and after each exposure and their relative degradation classified. Data demonstrate that AZO degraded most rapidly of all the TCOs, whereas ITO and FTO degraded at lower to non-quantifiable rates. One approach to suppress degradation could be to use interfacial layers (IFLs), including organofunctional silane layers, to modify the TCO. We modified the TCO surfaces using a variety of organofunctional silanes, and determined a range of surface energies could be obtained without affecting the electrical and optical properties of the TCO. Degradation studies of TCOs with a silane layer were also conducted. We found that an inhomogeneous silane layer was able to delay the resistivity increase for ITO in DH. INTRODUCTION In the movement toward renewable energy sources, the cost of solar power is often cited as a primary limiting factor for its widespread adoption. One effective way to reduce the levelized cost of energy (LCOE, the total cost of the installation levelized over its’ lifetime) is to increase the lifetime of the installation. Many components in PV systems require lifetime extension; however, TCOs (transparent conductive oxides) are an identified failure mode in many PV technologies that hold the potential to be cost-effective. Transparent conductive oxides (TCOs) have widespread utility in PV and other optoelectronic devices such as display screens, and organic light emitting diodes (OLEDs). The combination of conductivity and optical transparency makes them ideal electrical contacts in these systems. However, when deployed in the field, additional requirements for lifetime and durability arise. Delamination at the TCO-absorber interface has been reported for both thin film silicon solar modules 1 and OPV technologies. 2 In the bulk TCO, an increase in resistivity and structural changes are observed. 3 In CIGS photovoltaics, replacing the TCO of a fully degraded cell restores its properties to near peak performance. 4 TCO surfaces can be modified by the addition of a thin polymer layer, silanization (resulting in covalent bond formation), and the chemisorption of small molecules. 5,6 PEDOT:PSS (poly(3,4-ethylenedioxythiophene) poly(styrenesulfonate)) is a polymer commonly used as an electron blocking layer in OLED and OPV devices. 7,8 PEDOT:PSS is highly acidic and therefore corrosive to the TCO layer. 9,10,11 Allen et al. demonstrated that placing a monolayer of silane between the PEDOT:PSS and the TCO blocked this interaction without affecting the performance of the OLED.9 Silane and small molecule modifications of TCOs have also been used to optimize rates of charged carrier transfer, and increase the compatibility of the polar TCO with nonpolar materials used in OPVs and OLEDs.7 In this study, three commercially available TCO materials on glass were exposed to three types of accelerated environmental exposures. Degradation was characterized by monitoring changes in their optical and electrical properties and surface free energies. Silanes with a range of functionalities were chosen to modify ITO: amine-terminated APDMES (3aminopropyldimethylethoxysilane) and APTES (3-aminopropyltriethoxysilane), allylterminated ATES (allyltriethoxysilane) and methyl-terminated OTS (octadecyltrichlorosilane). ATES and OTS hold particular interest because of their previously demonstrated utility as interlayers in organic electronics. 12 Finally, allyltriethoxysilane (ATES), used by Allen et al., was applied to TCO samples and subjected to two accelerated exposures, characterizing the degradation in comparison to the bare TCO. EXPERIMENTAL METHODS ITO (Colorado Concept Coatings LLC, Xin Yan Technologies), AZO (Zhuhai Kaivo Electronic Components Co., Ltd.), and FTO (Hartford Glass Company Inc.) on glass were purchased commercially. Samples were cleaned before collecting contact angle data (before and after the accelerated exposure). Sample cleaning involves a series of 10 min sonications in 30 °C detergent solutions, DI water and/or solvents (acetone, methanol and isopropanol), drying under nitrogen gas, and a 15 min UV ozone clean at 60 °C (Novascan PSDP-UV8T). Note that gentle scrubbing with an optical wipe was used after the IPA sonication to remove strongly adhered surface species after damp heat exposure. After cleaning, silane films were deposited by exposure of the TCO to a silane/anhydrous toluene solution; see Table I for the deposition condition summary. For all samples, the deposition was followed by a series of solvent rinses (anhydrous toluene, chloroform/dichloromethane, and methanol/ethanol), drying under nitrogen, and a 10 min bake at 120 °C. Silanized TCOs post environmental exposure were cleaned using the procedure described above, omitting the UV-ozone exposure, as this removes the silane layer. Table I. Silanes and their deposition conditions used in this study. v/v (silane/ Solution Silane Time (min) anhydrous toluene) temperature (°C) APDMES 0.2% 2-60 60 APTES 1% 2-60 60 OTS 0.2% 5-60 90 ATES (1) 1% 10 RT ATES (2) 1% 10 RT Agitation None None None None Periodic Three types of accelerated exposure were used in this study; modified ASTM G154 (“hot irradiance”, 70 °C, 1.55 W/m2 @ 340 nm, comparable to 5X Suns UV irradiance), ASTM G154 (“cyclic”, 8 h @ 70 °C, 1.55 W/m2 @ 340 nm, 4 h @ 50 °C with spray in dark), and IEC 61626 Damp Heat (“DH”, 85 °C, 85% relative humidity). Samples were subjected to exposures for up to 1000 h in ~168 h (1 week) increments; samples were arranged in the environmental test chambers such that the TCO/TCO-silane surface directly exposed. After each exposure step, 2-3 samples were removed, cleaned, characterized and stored. To quantify the properties of the TCO, optical, electrical and surface measurement techniques were used. The surface free energy (SFE) was calculated from contact angles with water and diiodomethane using the Kruss EasyDrop, DSA4 system and the Wu method. The unexposed TCO SFE can be seen in Table II. Reported contact angle values are the average and standard deviation of five 50 frame video measurements on 1-2 samples; SFEs are calculated from these contact angles. Note 1 mJ/m2 = 1 mN/m = 1 dyne/cm. Table II. Baseline surface free energies and contact angles of TCOs using the Wu method. SFE ITO AZO FTO 2 2 78.8 ± 0.3 mJ/m 80.5 ± 2 mJ/m 82.2 ± 0.1 mJ/m2 Total 37.9 ± 0.3 mJ/m2 40.9 ± 1 mJ/m2 42.8 ± 0.1 mJ/m2 Disperse 41 ± 0.1 mJ/m2 39.6 ± 0.5 mJ/m2 39.4 ± 0.03 mJ/m2 Polar 4.5° ± 0.2° 7.2° ± 0.5° 2.3° ± 0.2° Water C.A. 28.5° ± 0.3° 17° ± 2° 5.7° ± 0.4° Diiodomethane C.A. Transmission spectra were obtained using a Varian Cary 6000i or an Ocean Optics USB 4000 Fiberoptic UV-Vis Spectrophotometer. Percent haze, yellowness index, L*, a*, and b* values were obtained using a Hunterlab UltraScan Pro Colorimeter. The resistivity of the ITO films was measured using an EDTM R-chek four point probe, and the resistivity of the AZO and FTO films was measured using a Keithley 2400 Source and Lucas Labs four point probe. Elemental analysis was performed using a PHI Versaprobe 5000 Scanning X-Ray Photoelectron Spectrometer (XPS). Spectra were collected using a monochromatic Al Kα Xray source (1486.6 eV, 75 W), hemispherical analyzer, and multichannel detector, with dual beam charge compensation (10 eV electron flood gun and compensating 10 eV argon beam gun). Data were collected over 1.1 x 0.270 mm areas. Reported values are averages and standard deviations of 3 high-resolution measurements, collected using an analyzer pass energy of 23.50 eV and a step size of 0.2 eV/step. RESULTS AND DISCUSSION Surface cleaning of the TCO after exposure is critical to tracking changes in the SFE. Fig. 1 shows the water contact angle as a function of exposure time for ITO exposed to damp heat and hot irradiance. Both treatments increase the water contact angle due to random surface species accumulation Figure 1. Water contact angles are sensitive to surface free on the highly reactive TCO energy changes of cleaned TCOs. surface, demonstrated by the plateau. However, if cleaned before contact angle measurements are taken, using the same procedure as for the TCO baseline, the contact angle is discovered to trend with exposure time, making it an excellent degradation indicator. TCO Degradation AZO was the least durable of the TCOs studied in this work: all properties degraded in all exposure types with exposure time. For example, in the cyclic exposure, the yellowness index, percent haze, and resistivity all increased steadily with exposure time (Fig. 2a.). The transmission spectra also changed with exposure time (Fig. 2b.); the interference fringes seen in the AZO film, whose period is a function of film thickness, shift with time, indicating a change in film thickness. Additionally, the peak-trough height of the fringes decreased, indicating a decrease in reflectivity of the surface, suggestive of surface roughening. These observations are consistent with the modes of AZO degradation found by Pern et al., who reported that their AZO film degraded rapidly and became porous after DH exposure.3 Fig. 2a. Electrical and optical properties of Fig. 2b. Transmission spectra of AZO reveals AZO increase with exposure time. structural film changes. In contrast to AZO, the resistivity, yellowness, and transmission spectra of the FTO did not change under any of the exposure conditions studied here (data not shown). FTO was also found to be most stable by Pern et al.3 The ITO films in this study were found to be stable except for a small increase in resistivity with DH exposure. TCO material properties were least affected by the hot irradiance exposure. In principle, the hot irradiance exposure resembles the UV-ozone exposure used as the final cleaning step. It was found that the hot irradiance exposure maintained a lower water contact angle than either the DH exposure of an un-cleaned, unexposed sample (~75°), as seen in Fig. 1, indicating that the exposure acts as a gentle UV ozone clean. This also explains the almost complete lack of degradation seen in this exposure type. Silane IFL customization ITO was modified with APDMES, APTES, OTS and ATES. Water contact angles measured on silane-modified ITO films are displayed in Fig. 3 as a function of deposition time, tdep. Water contact angles range from 57 - 94°, and are consistent with literature values for these silanes on glass or silica surfaces.10,13,14,15,16 While APDMES and APTES both have amino functional group terminations, the differing number of reactive ethoxy groups results in distinct film morphologies, apparent in the water contact angles. APDMES has one hydrolyzable ethoxy group, which allows for a single bond to be made to the TCO surface, resulting in a self-limiting monolayer 13; thus, increasing tdep does not affect the contact angle, which is consistent with reported values for APDMES monolayers on glass (62.5°). 14 APTES has three hydrolyzable ethoxy groups, allowing for multiple points of surface Figure 3. Water contact angles of several silanes on ITO. attachment and polymerization with other APTES molecules, which can result in formation of a multilayer. Thus, increasing the tdep typically results in a thicker, rougher film.10, 15 Due to vertical and horizontal branching, the film structure is complex and can be quite inhomogeneous. The increased contact angle compared to the APDMES monolayer is attributed to surface methyl groups from the branched structure. These methyl groups are known to increase the measured contact angle compared to a pure amine-terminated surface.15,16 As expected, OTS films have among the highest contact angles, due to the methyl-terminated long chain. ATES is a triethoxysilane, like APTES, and similarly can deposit multilayer films. The film structure is sensitive to the deposition conditions, including agitation of the deposition solution; agitation increases the water contact angle by ~ 20°. ATES was also deposited (with agitation) on FTO and AZO surfaces. The SFE of ATES on the three TCOs are presented in Table III. All ATES treated TCO surfaces are hydrophobic, as opposed to the Table III. SFE and contact angles of ATES on TCOs using Wu method. SFE ITO AZO FTO 2 2 37.4 ± 3 mJ/m 35.6 ± 0.7 mJ/m 34.8 ± 2 mJ/m2 Total 29.8 ± 0.4 mJ/m2 31.1 ± 0.2 mJ/m2 31.8 ± 0.8 mJ/m2 Disperse 7.7 ± 2.4 mJ/m2 4.5 ± 0.5 mJ/m2 3 ± 1.4 mJ/m2 Polar 88° ± 5° 96° ± 1° 99° ± 3° Water C.A. 52° ± 1° 51° ± 3° 51° ± 1° Diiodomethane C.A. bare clean TCO surface; the silanized TCO SFEs are nearly half of the bare, clean TCO value (see Table 2), and these surfaces are more hydrophobic than an air-exposed TCO, indicating the presence of the silane. XPS was conducted on these samples to confirm and semiquantify the deposition of the silane layer. Si, which is not present in the bare TCOs, was detected by XPS on all three silanized TCOs. The %Si (of the total atomic percent) was 2 ± 0.4%, 1 ± 0.4%, and 0.6 ± 0.2% for AZO, ITO and FTO respectively, indicating that the surface coverage could depend on the original TCO material. Measurements of the optical and electrical properties of the silanized TCOs indicate that the modification procedures did not significantly affect the conductivity or the transmission of the TCO. All resistivity values were 48 ± 1 ohm/sq, before and after silane deposition. Transmission in the visible range was defined as the average %T between 400 and 800 nm; %T is 93 ± 1 for clean ITO. Treatment with ATES and APDMES did not affect the measured %T; however, treatment with OTS and APTES lowered %T to 89 ± 1, comparable to the PEDOT:PSS-modified ITO (%T = 89 ± 2). TCO+Silane Degradation The effects of silane modification (ATES, without agitation) on the critical properties of the TCOs were examined after DH and hot irradiance exposures. The AZO was still severely affected by the DH exposure, with no observed reduction in degradation rate. The FTO showed no degradation with or without silane in DH. However, the ITO, which had a small increase in resistivity over the course of a 4 week DH exposure, demonstrated a delayed, slightly smaller resistivity increase when protected with a silane layer, as seen in Table IV. Table IV. Resistivity increase of ITO in DH with and without silane. Resistivity (Ω/sq) of ITO Time (h) Damp Heat Damp Heat with ATES 0 48.9 ± 0.2 48.9 ± 0.2 168 52.0 ± 0.5 48.8 ± 0.6 336 52.3 ± 0.7 50.0 ± 0.4 Note that the ATES modified TCOs used in the exposure studies (deposited without agitation) had lower contact angles and a larger deviation than those deposited with agitation. The contact angles indicate the presence of a silane layer, but the large deviation within samples and between deposition batches suggest inhomogeneous coverage. A more homogeneous or thicker film may better preserve the TCOs electrical properties. In the hot irradiance exposure, all TCOs’ SFEs after exposure demonstrated that the silane layer had been removed from the TCO. The water contact angles after the exposure have nearly the same hydrophilicity seen in bare, clean TCO surfaces (see Table V). This is Table V. Water contact angles of bare, ATES silanized, and hot irradiance exposed TCOs. Bare TCO, TCO with ATES, TCO with ATES, Unexposed Unexposed Post Hot Irradiance 4.4° ± 0.5° 74° ± 2° 20° ± 2° ITO 7° ± 1° 78° ± 2° 9° ± 1° AZO 2.3° ± 0.5° 75° ± 4° 3.5° ± 0.3° FTO reasonable and expected, given that UV ozone clean would remove the ATES and that the hot irradiance exposure simulates a low intensity UV ozone clean. A silane layer in an encapsulated configuration would be affected differently by the hot irradiance exposure. CONCLUSIONS In this study, AZO, ITO and FTO were exposed to three types of accelerated environmental exposures, and their optical and electrical properties and SFE were characterized. It was found that AZO degraded most rapidly of all the TCOs in all the exposure types, whereas ITO and FTO degraded at lower to non-quantifiable rates. A variety of silane layers (APDMES, APTES, ATES and OTS) were applied to the TCOs; varying the functional groups of a silane is an effective way of modifying the surface energy of the TCO without affecting other critical properties such as %T and resistivity. The ATES molecule was then selected for use in a degradation study. It was found that the inhomogeneous silane layer was able to delay the increase in resistivity for ITO in DH exposure. It was also found that the hot irradiance exposure removed the silane from the TCO surface, seen in the decrease in water contact angles to be comparable with a bare, clean TCO. ACKNOWLEDGEMENTS The authors would like to thank Underwriters Laboratories for their support of this research. REFERENCES 1 C.R. Osterwald et al., National Center for PV and Solar Program Review Meeting, Denver, CO, 24 (2003). M.O. Reeseet al., Solar energy Mat. & Solar Cells 92, 746-752 (2008). 3 F.J. Pern et al., PVSC:IEEE, 1 (2008). 4 R. Sundaramoorthy et al., SPIE Solar Energy+ Technology, pp. 74120J-74120J (2009). 5 M. Brumbach and N.R. Armstrong, Ency. Electrochem. (2007). 6 N.R. Armstrong et al., Accounts Chem. Res. 42 (11), 1748-1757 (2009). 7 N.R. Armstrong et al., Macromolecular Rapid Comm. 30 (9-10) 717-731 (2009). 8 N. Koch et al., Appl. Phys. Lett. 82 (1), 70-72 (2003) 9 N. Grossiord et al., Organic Electronics 13 (3), 432-456 (2012). 10 C.G. Allen et al., Langmuir 24 (23), 13393-13398 (2008). 11 M.P. de Jong et al., Appl. Phys. Lett. 77, 2255 (2000). 12 G. Sauve et al., J. Mat. Chem. 20, 3195-3201 (2010). 13 R.A. Shircliff et al., Langmuir, In Press (2013). 14 S.M. Kanan et al, Langmuir, 18 (17), 6623-6627 (2002). 15 J.A. Howarter and J.P. Youngblood, Langmuir 22 (26), 11142-11147 (2006). 16 H. Menzel and A. Heise, Langmuir 13 (4), 723-728 (1997). 2