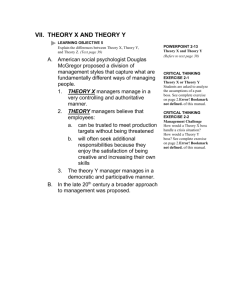

The multi-object, fiber-fed spectrographs for the Sloan Spectroscopic Survey

advertisement