Materials Characterization and Acoustic Performance of Piezoelectric Membranes

advertisement

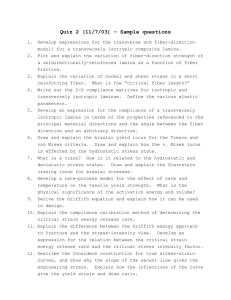

Materials Characterization and Acoustic Performance of Piezoelectric Membranes Andrew Davis, Dr. David Bahr, Dr. Mike Anderson WSU REU 2011 Materials Science and Engineering Introduction & Objectives Future Work A new class of acoustic transducer with a polyvinylidene fluoride (PVDF) membrane utilizing in plane tension and out of plane geometry shows higher acoustic properties than un-stressed PVDF counterparts. The polynomial used in the pressure deflection curve is a very good approximation for isotropic materials, but PVDF is transversely isotropic which means that there will be a degree of uncertainty in the results. It is important to develop a cubic polynomial for transversely isotropic membranes. The way to do this is by expanding upon the work done by Timoshenko. Goals: • Take into account the transversely isotropic nature of PVDF membranes. • Test membranes with uniaxial stress to determine properties. Test acoustic performance when stressed parallel and perpendicularly to the strain of manufacturing. Nxy Ny 0 x y Nx Nxy 0 x y • Strain Components: u 1 x x 2 x 2 1 y y 2 y 2 u xy y x x y • Secondary strain components: Transducer mounted with leads attached to measure amplitude resonance. This shows a typical pressure deflection curve. The regression shown in green has only a linear and a cubic term. From here the value of the elastic modulus was calculated. 1 1 Nx Ny y Ny Nx x hE hE 1 xy Nxy hG • Strain components combined to form stress function: P0 N x 2 N y 2 2 N xy 0 x y xy 2 2 2 • The new polynomial will include the transversely isotropic stiffness matrix with 5 engineering constants: two elastic modulus, two Poisson's ratio, and one shear modulus. • By assuming the coordinate system to be centered around the center of the transducer, using boundary conditions, and symmetry of strain, progress can be made toward developing the polynomial that can be regressed to determine the elastic modulus of transversely isotropic materials. Acoustic Performance Progression from circular transducer to an infinitely long rectangle means that stress is added only in the direction of the small side length. Projections show that a lower pre-stress would allow initial experiments to be run at relatively low pressure situations. Deflection (um) • Stressing the membrane in the direction of original fabrication strain produces a higher acoustic response than unstressed membranes or membranes stressed perpendicularly to fabrication strain. These figures show that as the pressure increases the resonating frequency shifts upward drastically when the differential pressure increases. This also confirms that the symmetry of PVDF cause zero bending actuation at zero pressure, causing the drop. Changing Pre-Stress to Observe Cubic Shape Conclusion • Using a rectangular transducer with an aspect ratio of around 5 it is reasonable to assume that the stress is uni-axial and therefore directional properties can be approximated. When the rectangular transducer is stressed nearly all of the stress is in the direction of the small side as shown. Differential Pressure (kPa) • • Equations of equilibrium for applied stress: References • J.J. Vlassak, W.D. Nix, “A new bulge test technique for the determination of Young’s modulus and Poisson’s ratio of thin films”, Journal of Materials Research, Vol. 7, No. 12, 3242-3246 (1992). • S. Timoshenko, “Theory of Plates and Shells” (1959). This “Gullwing” plot shows the lowest response at zero differential pressure, increases for a short range of pressure, then the response drops drastically. To all in the MEMS lab who answered questions and gave advice, thanks. This work was supported by the National Science Foundation’s REU program under grant number DMR-1062898