D S E R

advertisement

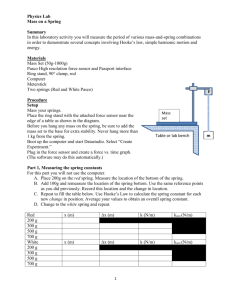

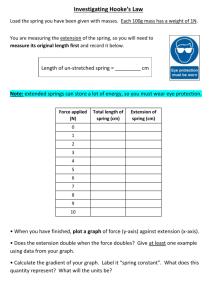

DEVELOPING A SYSTEM DYNAMICS EXPERIMENT FOR REMOTE LABORATORIES Katie Hauser and Jitesh Panchal School of Mechanical and Materials Engineering INTRODUCTION WSU’s School of Mechanical and Materials Engineering now offers an ME degree program at Olympic College in Bremerton, WA. While many courses in the program will be taught at Olympic College, other courses will be taught remotely from WSU. One of the challenges of remote learning is the simulation of laboratory experiences, which are an important component of engineering programs. While it makes little sense to teach a lab-only course remotely, it could be beneficial to students’ learning if distance lecture courses included supplementary remote experiments and demonstrations. Creating the experiment is the first step in determining whether an experiment, located at WSU and controlled over the Internet, would improve distance students’ learning of concepts in engineering lecture courses. The goal of this project was to develop a mass-spring system with features to facilitate its future development into a remote experiment for the course ME 348: Dynamic Systems. PROCESS The design process for the system dynamics simulation began with determining objectives, which are the desired attributes of the final design; functions, which are actions the design must perform; and constraints, which are strict limits the design must adhere to in order to be acceptable.With these in mind, a list of needed components was made, and options for each component were found or later designed. Objectives •Modular in design •Scientifically useful •Resistant to wear and tear from repeated student use •Cost-effective •Conducive to remote procedure development Functions •Hang springs, dampers, masses •Output displacement and force data •Force mass-spring system in a step, ramp, or sinusoidal manner Constraints TESTING Tests were conducted on the components of the apparatus to ensure their viability before creating the final design. Springs and Masses In order to make sure the PASCO springs and masses would be compatible, each mass was hung from each spring and set oscillating. Results: •Alone, the 10 & 20 g masses do not displace any of the springs •The 1 kg mass will overstretch springs when the effective spring constant is less than 40 N/m •Displacing by pulling downwards beyond a system’s maximum amplitude often causes the mass to fall off the spring; displacing by pulling upwards does not Damping With mathematical tests it was determined that dampers from Ace Controls would be too strong for the PASCO springs and masses. After obtaining a sampleAirpot dashpot, whose damping coefficient is adjustable, it was determined that these would be suitable for the apparatus and would be more repeatable than magnetic damping made in-house. Sensors Due to the cost of ready-for-use PASCO sensors, sensors from Sharp and Flexiforce were tested first with the idea that if they did not work well enough, the PASCO sensors would be tried. Sharp Infrared Proximity Sensor GP2Y0A21YK These sensors output a voltage that varies as the target object moves from 10 cm away to 80 cm away. Initial test results: •At a given distance, the sensor readings (taken every 10 ms) had a significant upward trend •Periodically (about once per second), a single reading would jump much higher than its surrounding readings After programming the Arduino microprocessor to print the average of 1 ms readings every 10 ms and powering the sensor with 3.3 V instead of 5 V (thus increasing the range of possible output values), the standard deviation of outputs in each trial was greatly reduced, and the sensor was then calibrated. No particular constraints were determined initially. By reviewing design progress often, any unwanted features could be noted and removed without having spent significant time on developing them. FINAL DESIGN The final design incorporates: •Six PASCO springs of three spring constants •Four Airpot dashpots with different, fixed damping coefficients •Nine PASCO hooked masses from 10 g to 1 kg •Three Flexiforce pressure sensors along the top of the frame •Three adjustable-position Sharp IR Sensors •One Arduino microprocessor and electronics •Two 1.7 kg PASCO A-frame rod stands •Two 90 cm PASCO rods •One computer running Linux and Kst for plotting sensor output in real time The design also incorporates a number of custom parts: •One 16 in top bar with hooks •One 16 in bottom bar/track for sensors •Five 2x1 in sliding platforms for displacement sensors and forcing motors •Brackets for connecting springs, dampers, and masses in various configurations CONCLUSIONS & FUTURE WORK The system dynamics simulation described by this design will function as a normal, in-person experiment. However, key features of the current design will facilitate its development as a remote experiment: •Interchangeability of springs and dampers •Computer integration •Low-profile, easily-modified frame •Highly controllable sensor behavior and precision •Customizable real time data plotting Components •Frame – supports system, hangs springs and dampers, holds sensors in place •Springs – at least six, same length, multiple spring constants •Masses – various weights, easily hung from springs •Damping – repeatable, various damping coefficients •Forcing – repeatable, variable •Force & Displacement Sensors – precise, connect to computer •Computer – display sensor data graphically Screenshot of Kst, a real-time graphing program Future design work will include such tasks as: •Automating spring arrangement and displacement •Developing a interface for remote users •Developing a secure network over which to broadcast visuals and data Once the remote experiment has been fully developed, research will be done to determine whether it is a useful learning tool. The understanding and success of four groups of students in ME 348: Dynamic Systems will be compared: A Sharp IR sensor (lower left) connected to an Arduino microprocessor Components (clockwise from top): 1. PASCO Springs (40, 20, & 10 N/m) 2. PASCO Masses (500, 200, & 100 g) 3. PASCO Weighted Base 4. Airpot Dashpot (Damping Device) •Local students who performed the experiment in person •Local students who did not perform the experiment •Remote students who performed the experiment remotely •Remote students who did not perform the experiment FlexiforcePressure Sensor (25 lbs) These are piezoresistiveforce sensors; the greater the force on the sensor, the lower the output resistance. Initial tests of the sensor showed that its outputs tended to increase over time, making calibration difficult. Conditioning the sensor may ease this problem. The team expects to have the resources to condition the sensor properly within the next few weeks, after which the sensor can be calibrated for use in the apparatus. ACKNOWLEDGEMENTS Many thanks go out to Dr. Carl Hauser for assisting with programming, Ken Lafleur from Airpot Corp. for his advice in choosing dashpots, and Henry Ruff for helping with the design and building of the custom parts. This work was supported by the National Science Foundation’s REU program under grant number EEC 0754370