Preparation and Characterization of Carbon Nanotube Reinforced Polyetherimide

advertisement

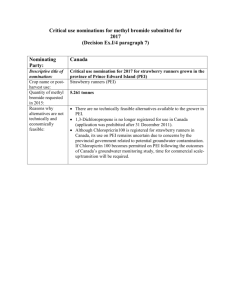

Preparation and Characterization of Carbon Nanotube Reinforced Polyetherimide Composites by Solution Mixing Method Santiago Caceres Cal Poly, San Luis Obispo - WSU - REU Program Dr. Sandeep Kumar (Project Supervisor), Dr. Katie Zhong (Faculty Advisor) School of Mechanical and Materials Engineering Washington State University, Pullman, WA 99164 This work was supported by the National Science Foundation’s REU program under grant number DMR-0755055, NSF grant number 0758251, and the Boeing grant Method: The goal for processing was to effectively transfer the potential mechanical and electrical properties of the MWNTs to the PEI matrix. The two main challenges involved with the fabrication of novel nanocomposites are: ! Dispersion ! Interfacial Bonding Procedures: PEI Powder Dispersion of the multi-wall carbon nanotubes in the nano-composites was characterized $!"" by field scanning electron microscope( FESEM). It was observed that functionalized MWNTs were homogeneously dispersed and embedded within the polyetherimide matrix. Figure 2 (a) shows good interfacial interaction, while Figure 2 (b) shows $""" dispersion of MWNTs within the PEI matrix. & '()* + , -.(/0102 3-.4 * Polyetherimide (PEI), is a high performance thermoplastic known for its high heat resistance and good mechanical properties. By adding nanoscaled fillers into the PEI matrix, we may be able to obtain unique properties in the newly formed composite. If the mechanical and electrical properties can be improved by the introduction of an effectively dispersed nano-filler through the appropriate method, this high performance polymer nanocomposite may be considered as a multifunctional interior material in the next generation of safe, fuel efficient light weight aircrafts, and other low density high performance applications. The dispersion behavior, mechanical, thermal and electrical Multi walled carbon nanotube properties of functionalized multi walled carbon nanotube (MWNT)-PEI nanocomposites were investigated. !" $!"" $""" #!"" #""" #"" #!" " !" $"" #"" ( 5,67,)*'0),3 8 $!" #!" %"" $"" $!" %"" Temperature, ! ( 5,67,)*'0),3 8 Figure 6. DMA results for various MWNT loading and scheme of Systematic mechanism of increase in storage modulus with temperature. !"#$%$&'(&!#)*+&,#$&%$"#-./+%&)0&/.,$10-"/-2&1$-",/).&)0&34456789:+ */,#&;),#&<=>& Figure 2. FESEM images of PEI/MWNT composite showing good adhesion left (0.5 wt% MWNT) and dispersion right (1.0 wt%, (MWNT) Interfacial Interactions: Thermogravimetric Analysis (TGA): Temperature, ! Figure 4. TGA Graph of Pure PEI and nanocomposites Electrical Analysis: Figure 3. Mechanism of interfacial interaction of COOH-MWNTs with PEI TGA graph in figure 4 show the thermal stability of PEI/ MWNT composites increase as MWNT loading increases. This suggests that the MWNTs act as a mass-transport protective barrier that slows down degradation of the polymer. Pure PEI PEI MWNTs ( 0.5 wt%) PEI MWNTs ( 1.0 wt%) PEI MWNTs ( 7.0 wt%) DMA showed high increase in storage modulus (E') with the incorporation of MWNTs as compared to pure PEI. The increase was due to decreased mobility of the polymer chain due to the formation of plenty of cross linking sites between polymer and MWNTs. Electrical properties of the PEI/MWNT composites were investigated. The results show that the percolation behavior lies between 0.3 and 0.5 wt% loading of MWNTs in the PEI matrix. the materials electrical resistivity dramatically drops from about 17 ohm*cm to 5.5 ohm*cm. By adding a COOH group to the MWNTs, interfacial interactions between the two materials can be much stronger and therefore transfer the nano fillers properties much more efficiently to the matrix. Figure 3 shows the mechanism of this interaction. PEI/MWNT In DCM Mixture >Ultrasonication (45min) > Sample Left overnight for DCM evaporation !" #$% !"PEI &' Pure !"#$% !" &'() * +,-.!/01!234 5 !"&' PEI MWNTs ( 0.5 wt%) !"& * +,-.!/01!234 5 !" &'() * +,-.!6 0/!234 5 '() PEI MWNTs ( 1.0 wt%) !" '() * +,-.!6 0/!234 5 !" &'() * +,-.70/!234 5& PEI MWNTs ( 3.0 wt%) !" '() * +,-.70/!234 5 PEI MWNTs ( 7.0 wt%) !" &'() * +,-.80/!234 5& !"&'() * +,-.80/!234 5 " Weight Loss % PEI/MWNT In DCM Mixture >Stir (1hr) #""" %""" !"" MWNT MWNT In DCM >Sonication (1hr) >Ultrasonication (15 min) PEI In DCM >Stir (1hr) #!"" !"" ! PEI was dissolved in methylene chloride (DCM) and stirred for at least 1 hour. ! Functionalized MWNTs were dissolved in DCM, sonicated for 1 hour, then immediately placed into horn type Ultrasonication for 15 minutes. ! The MWNT solution was then mixed with the PEI solution and stirred for 1 hour. !PEI/MWNT solution Ultrasonicated 45 minutes. ! Solution cast into a glass dish, covered, and left to dry overnight ! Samples removed from glass dish and dried in a oven for at least 4 hours at 60 !. Dynamic Mechanical Analysis (DMA): %""" & '()* + , -.(/0102 3-.4 * SEM Analysis: Introduction: PEI Matrix Figure 7. Graph showing Resistivity Vs. wt% loading for MWNT-PEI composites. Percolation for electrical conductivity is observed between 0.3 - 0.5 wt% loading. Conclusions: Dispersion behavior, mechanical, thermal and electrical properties of functionalized MWNT/ PEI nanocomposites were investigated: ! Alternating sonification and ultrasonification PEI/MWNT Composite Film > Film Dried in oven 4 hrs at 60 ! Morphology (FESEM) Electrical Properties Thermal Properties Film Sample Viscoelastic Properties Figure 1. Process procedure outline Figure 5. Mechanism of how MWNTs impede the removal of bulk PEI from going to the vapor phase. MWNT Interphase Figure 5. Scheme showing resone for increase in Tg of nanocomposites is a successful method of dispersing MWNTs in a PEI matrix ! The addition of functionalized MWNTs significantly increases PEI’s thermal stability ! PEI’s storage modulus is increased due to support provided by the MWNTs reinforcement. ! Electrical Percolation is observed between 0.3 and 0.5 wt% loading