Mechanical response of carbon nanotubes turfs under lateral strains

advertisement

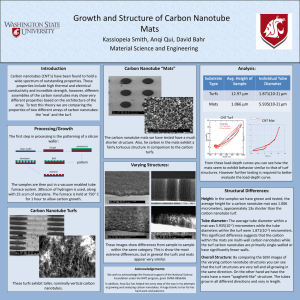

Mechanical response of carbon nanotubes turfs under lateral strains Melinda C. Lopez, David F. Bahr Intro to Multiscale Engineering School of Mechanical and Materials Engineering Introduction Carbon nanotubes have a broad array of applications due to their remarkable mechanical, electrical, and thermal properties. In particular, they have been observed to be among the strongest materials tested in tensile loading and possessing one of the highest elastic moduli. Much of the research though has been conducted on the mechanical properties of single carbon nanotubes under stress, with less performed on large collections of carbon nanotubes, or “turfs”, and their response under different strains. In this experiment the mechanical response of carbon nanotube (CNT) turfs are examined by nanoindentation under different strains. (a) (b) Figure 1. Array of CNT turfs at (a) 0% and (b) 3.5% strain Materials and Methods The CNT turfs are mechanically transferred to a substrate using the method developed by Ryan Johnson [1]. The CNT turf is placed on top of a Kapton coated in 300 nm of gold. The two are then placed for two hours in a furnace 150° C under a stress equal to that of the buckling stress of the CNT. Figure 2. An illustration of how the carbon nanotubes were transferred to the gold coated Kapton. The CNT turfs were tested using nanoindentation at 0% strain and at 3.5 % strain, where the gold coated Kapton containing the transferred CNT turf is placed in a vice and fastened. The CNT turf is then manually stretched in this machine reaching a strain of 3.5% prior to the gold film cracking. Larger strains can be achieved, but 3.5% is the upper limit used for this system. (a) Figure 3. The vice used to manually stretch the CNT turf Once the transfer and strain had been completed, the mechanical response of the CNT turf is observed using nanoindention using the Hysitron Triboscope using dynamic mechanical analyzer, the same method as McCarter [2]. With this method, an oscillating force is applied to the carbon nanotubes allowing for multiple measurements to be taken on one location. In this particular experiment a frequency 30 Hz and a maximum force of 500 µN was used. Figure 4. An illustration of the nanoindenter tip used. In this particular test, the tip was a spherical in shape, and the diamond was gold coated to prevent adhesion from the carbon nanotubes Results At 0% strain, the nanoindenter reached an average depth of 1,313 nm, a minimum of 951 nm, and a maximum of 1,946 nm in the carbon nanotube turfs. The elastic modulus of the carbon nanotube, no matter where the indentation was made, levels out at 61.9 MPa. At 3.5% strain, the nanoindenter reached an average depth of 2,436 nm, a minimum of 1895 nm, and a maximum of 2,866 nm in the carbon nanotube turfs. The elastic modulus varies at this strain but is consistently lower than the 0 % strain. The CNT turf at 0% has a higher elastic moduli then the turf at 3.5 %, but does not indent as far. One reason the VACNT turf at 3.5 % strain appears to be stiffer is that as it is stretched, the area becomes less dense and exposes more of the gold coated Kapton. (b) Figure 5. Elastic modulus of carbon nanotubes at (a) 0 % and (b) 3.5% strain Figure 6. The moduli of a CNT turf at 0% strain in red versus the modulus of a CNT turf at 3.5% strain in black. Conclusions The objective of this work was to observe if there was a change in the effective elastic modulus of a carbon nanotube turf as it is induced under different strains. Nanoindentation showed that a carbon nanotube turf at 0% strain has a higher elastic modulus than when stretched to a 3.5 % strain, whereby the CNT turf appears to be a stiffer material. Literature Cited [1] Johnson R D, Bahr D F, Richards C D, Richards R F, McClain D, Green J, and Jiao J. Thermocompression boding of vertically aligned carbon nanotube turfs to metalized substrates. Nanotechnology 20, 6 (2009) [2] McCarter C M, Richards R F, Mesarovic S Dj, Richards C D, Bahr D F, McClain D, Jiao J, Mechanical compliance of photolithographically defined vertically aligned carbon nanotube turf. Journal of Material Science 41, 7872-7878 (2006) Acknowledgements I would like to give special thanks to Katerina Bellou and Ryan Johnson at WSU for their help in my research. This work was supported by the National Science Foundation's Research Experience for Undergraduates program under grant number EEC-0754370.