Chapter 3 3.1. Hazards.

advertisement

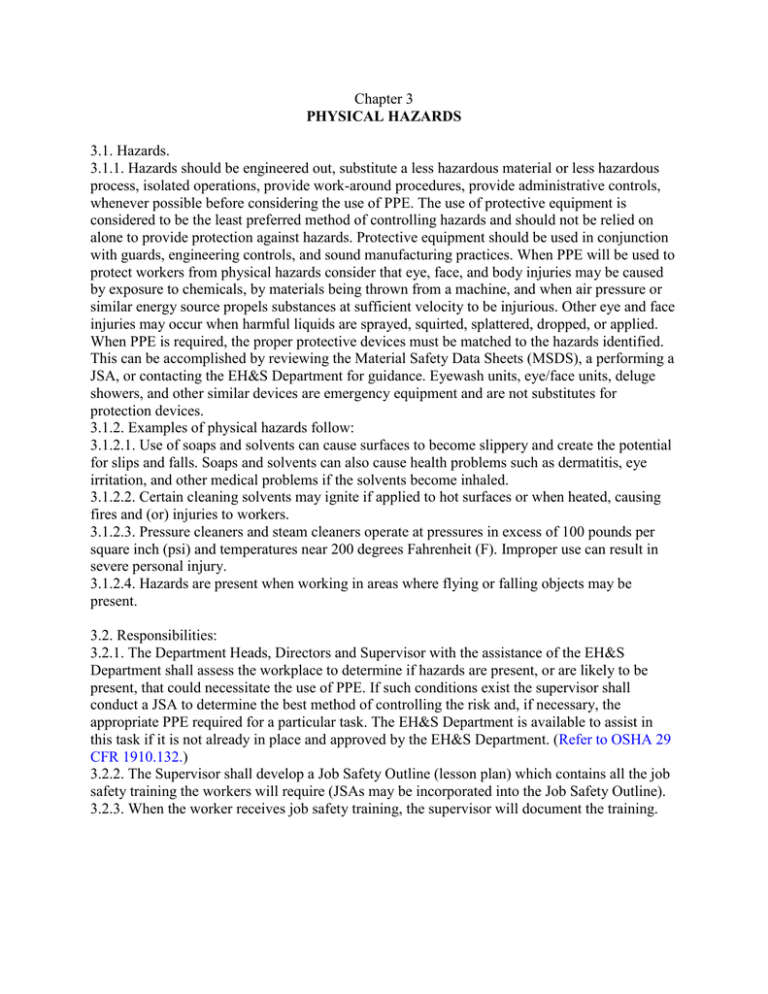

Chapter 3 PHYSICAL HAZARDS 3.1. Hazards. 3.1.1. Hazards should be engineered out, substitute a less hazardous material or less hazardous process, isolated operations, provide work-around procedures, provide administrative controls, whenever possible before considering the use of PPE. The use of protective equipment is considered to be the least preferred method of controlling hazards and should not be relied on alone to provide protection against hazards. Protective equipment should be used in conjunction with guards, engineering controls, and sound manufacturing practices. When PPE will be used to protect workers from physical hazards consider that eye, face, and body injuries may be caused by exposure to chemicals, by materials being thrown from a machine, and when air pressure or similar energy source propels substances at sufficient velocity to be injurious. Other eye and face injuries may occur when harmful liquids are sprayed, squirted, splattered, dropped, or applied. When PPE is required, the proper protective devices must be matched to the hazards identified. This can be accomplished by reviewing the Material Safety Data Sheets (MSDS), a performing a JSA, or contacting the EH&S Department for guidance. Eyewash units, eye/face units, deluge showers, and other similar devices are emergency equipment and are not substitutes for protection devices. 3.1.2. Examples of physical hazards follow: 3.1.2.1. Use of soaps and solvents can cause surfaces to become slippery and create the potential for slips and falls. Soaps and solvents can also cause health problems such as dermatitis, eye irritation, and other medical problems if the solvents become inhaled. 3.1.2.2. Certain cleaning solvents may ignite if applied to hot surfaces or when heated, causing fires and (or) injuries to workers. 3.1.2.3. Pressure cleaners and steam cleaners operate at pressures in excess of 100 pounds per square inch (psi) and temperatures near 200 degrees Fahrenheit (F). Improper use can result in severe personal injury. 3.1.2.4. Hazards are present when working in areas where flying or falling objects may be present. 3.2. Responsibilities: 3.2.1. The Department Heads, Directors and Supervisor with the assistance of the EH&S Department shall assess the workplace to determine if hazards are present, or are likely to be present, that could necessitate the use of PPE. If such conditions exist the supervisor shall conduct a JSA to determine the best method of controlling the risk and, if necessary, the appropriate PPE required for a particular task. The EH&S Department is available to assist in this task if it is not already in place and approved by the EH&S Department. (Refer to OSHA 29 CFR 1910.132.) 3.2.2. The Supervisor shall develop a Job Safety Outline (lesson plan) which contains all the job safety training the workers will require (JSAs may be incorporated into the Job Safety Outline). 3.2.3. When the worker receives job safety training, the supervisor will document the training.