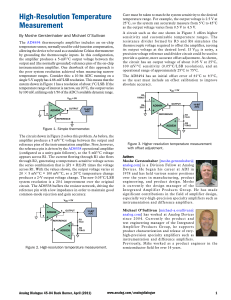

Volume 44, Number 4, 2010

advertisement