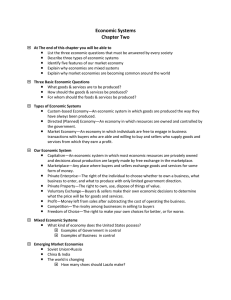

Document 11951161

advertisement