UNIVERSITY OF WISCONSIN – STEVENS POINT SAFETY ORIENTATION

advertisement

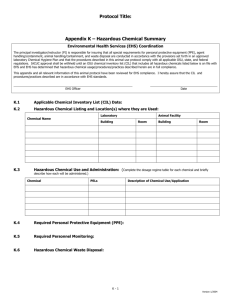

UNIVERSITY OF WISCONSIN – STEVENS POINT SAFETY ORIENTATION Environmental Health & Safety Officer Walter C. Clark, M.A. Reviewed and up-dated 8/31/2012 University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 1of32 TABLE OF CONTENTS SECTION PAGE 1 Accident Reporting…………………………………………………………..3 2 Asbestos Awareness………………………………………………………….3 3 Blood Borne Pathogens………………………………………………………5 4 Confined Space Entry Awareness ................................................................. ..6 5 Emergency Procedures……………………………………………………….8 6 Ergonomics…………………………………………………………………...8 7 Fire Extinguisher Safety Training…………………………………………….9 8 Hazard Communication………………………………………………………12 9 Hazardous Material (HazMat – DOT)………………………………………..18 10 Hazardous Waste……………………………………………………………...19 11 Hoisting Equipment…………………………………………………………..19 12 Housekeeping…………………………………………………………………19 13 Ladder Safety/Fall Prevention………………………………………………...20 14 Lead Awareness……………………………………………………………….20 15 Lockout/Tagout Awareness…………………………………………..……......21 16 Manual Lifting .............................................................................................. …23 17 Personal Protective Equipment (PPE)........................................................... …25 18 Powered Industrial Vehicles …………………………………………………..26 19 Tornado/Severe Weather Response ............................................................... …26 20 Other Information.......................................................................................... …28 21 Quiz……………………………………………………………………………29 University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 2of32 ACCIDENT REPORTING Employees who are performing work for the University and are on the University payroll are covered under Worker’s Compensation for work-related injuries. Injuries must be reported to your supervisor immediately. The closest medical facilities are St. Michael’s Hospital and Rice Medical Center. In the event of a medical emergency, 911 or Protective Services (x3456) should be called. The injured employee and the supervisor must complete worker’s compensation injury reports for any work-related injury. These forms must be submitted to the office of Safety & Loss Control within 24 hours. An accident investigation will be conducted for every injury. For additional information, or worker’s compensation packets, call Safety & Loss Control at x2618 or x2320. ASBESTOS AWARENESS What Is Asbestos? Asbestos is a collective name given to minerals that occur naturally and are found in the earth’s crust. Small amounts of asbestos may be found throughout the ambient environment. Asbestos is a material that is very resistant to heat and corrosive chemicals. In general, any building constructed before 1980 may likely have asbestos containing material (ACM) as it was widely utilized in the past due to its resilient properties. UWSP buildings contain a wide variety of asbestos-containing building materials (see examples below). A large percentage of public buildings and even private homes built before 1980 contain asbestos products. Asbestos is managed at UWSP following our Asbestos Management Program (see http://www.uwsp.edu/ehs/policy_downloads/policy.doc). UWSP ensures abatement projects follow asbestos management regulations and that other activities do not disturb asbestos still in place. Un-Milled Mineral Asbestos (Chrysotile) ACM Steam Insulation Sign For Regulated Area Typically, asbestos appears as a whitish, fibrous material which may release fibers that range in texture from course to silky; however, airborne fibers that may cause health damage may be too small to see with the naked eye. Heaviest exposures occur in the construction industry, particularly during the removal of asbestos during renovation or demolition and during manufacturing of asbestos containing products and asbestos mining. Examples of Materials That Could Contain Asbestos: Acoustical material (e.g., plaster, transite board, etc) Adhesives, caulks, glazing, mastics Ceiling tiles Thermal System Insulation (TSI) (e.g., pipe insulation, duct insulation) Fire-rated asbestos core doors Some plasters. Joint/spackling compound University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 3of32 Boiler/Furnace insulation Fire-stop material Lamp (insulation) Chalkboards Floor tile (especially 9”) and mastic Some spackling compounds Cooling towers Hair dryers (insulating material) Asbestos cement Surfacing material on walls or ceilings Heating pads Siding Textured surfacing material HVAC duct connectors Textured paints and coatings Transite panels (e.g.: garage, fume hood walls, etc.) Fire-resistant drywall Brake pads / Clutch disks Electrical insulation and wiring Theatrical (fire) curtains Fire-proofing material Roofing materials Roofing shingles and adhesives Vinyl sheet flooring Fire-protective clothing What Are the Dangers of Asbestos Exposure? Exposure to asbestos may cause asbestosis (scarring of the lungs resulting in loss of lung function that often progresses to disability and to death); mesothelioma (cancer affecting the membranes lining the lungs and abdomen); lung cancer; and cancers of the esophagus, stomach, colon, and rectum. Asbestos enters the body through inhalation or ingestion. Asbestos is primarily hazardous when breathed into the body. Therefore, preventing the material from becoming a dust is the critical exposure control measure. The symptoms of asbestos-induced diseases generally do not appear for 10, 20, or even 40 or more years after initial exposure. Friable asbestos is defined as being easily turned into a dust with only finger pressure. Most uncovered, dilapidated thermal system insulation is in this category. Non-friable asbestos does not meet this definition. However, non-friable material may become friable material by sanding, drilling, cutting, breaking, etc. ACM floor tile is an example of non-friable material. Friable material is the more hazardous form of ACM. According to the National Institute of Health: “Many studies have shown that the combination of smoking and asbestos exposure is particularly hazardous. Smokers who are also exposed to asbestos have a greatly increased risk of lung cancer. However, smoking combined with asbestos exposure does not appear to increase the risk of mesothelioma.” What Protections Are Mandatory? The U.S. Occupational Safety and Health Administration (OSHA) has issued regulations covering asbestos exposure in general industry and construction. Both standards set a maximum exposure limit and include provisions for engineering controls and respirators, protective clothing, exposure monitoring, hygiene facilities and practices, warning signs, labeling, recordkeeping, and medical exams. OSHA’s exposure limit for asbestos is 0.1 f/cc, 8-hour time-weighted average. UWSP follows a practice endorsed by the U.S. EPA known as: Management (Of Asbestos) In Place. The goal is to maintain existing asbestos containing material (ACM) in a stable condition rather than removal of asbestos for the sake of removing asbestos. The mere presence of asbestos does not constitute a hazard. If the ACM is maintained and undisturbed there is no exposure or risk to a building's occupants. Exposure may occur when the ACM is sanded, ground (using a grinder), abraded, or otherwise disturbed during maintenance operations, remodeling, abuse, or some other activity. Asbestos abatement is a routine occurrence in facilities University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 4of32 such as UWSP. Specific asbestos procedures may be found in UWSP’s Asbestos Management Program. See http://www.uwsp.edu/ehs/policy_downloads/policy.doc for further details. Key issues to remember with regard to asbestos safety include: • Practice consistent pre-assessment of your work area if performing maintenance activities which may disrupt asbestos containing building materials. Utilize the WALMS system (see below). • Report all suspect materials and questions to your Supervisor. • Damaged suspected or known materials - leave alone and report to your Supervisor. Restrict access to the area as needed (caution tape). • EHS will have asbestos sampling conducted where needed. Contact 2320. • Questions – Dick Bartosh (2320). • Abatement and repair work typically is contracted with outside approved contractor. • See Wisconsin Asbestos Lead Management System (WALMS) - http://walms.doa.state.wi.us/ for detailed asbestos inventory of UWSP buildings. USER ID = UWSP; PASSWORD = 1848. Select desired Building in top of screen, click “Material Inventory by Room” under Standard Reports, click “Display Report” right center. • Regulated areas. Areas that are being abated will be regulated and only authorized persons may enter a regulated area following safety practices. Warning signs must be displayed at each regulated area. • Ensure all individuals receive appropriate and required training. EHS offers 2-hour asbestos awareness training. Anyone interested in asbestos-related issues may attend. Employees who may be exposed to asbestos on the job are required to attend (maintenance individuals, building managers, etc.) and have an annual refresher. This training is free of charge to the department. Call 2320 for details. Individuals required to do basic work directly with asbestos (small repairs) must attend the 16-hour Operations and Maintenance class (contact EHS 2320). BLOODBORNE PATHOGENS - AWARENESS Bloodborne pathogens are microorganisms such as viruses or bacteria that are carried in blood and may cause disease in people. Bloodborne pathogens include: Malaria; Syphilis; Hepatitis B (HBV); and Human Immunodeficiency Virus (HIV). The Occupational Safety and Health Administration issued a standard on bloodborne pathogens to protect workers. Bloodborne pathogen waste will carry the following red or orange label: University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 5of32 This OSHA standard was enacted to help reduce workplace incidence of Hepatitis B virus (HBV) and human immunodeficiency virus (HIV) infection. Blood is the single most important source of HIV transmission in the workplace setting. Job classifications with potential occupational exposure to blood or potentially infectious materials have been identified. Employees who may encounter occupational exposure must be offered HBV vaccination within 10 working days of initial assignment. See Appendix B of the Bloodborne Pathogens Exposure Control Plan in the UWSP Health and Safety Manual for a listing of these positions. See http://www.uwsp.edu/ehs/policy_downloads/bloodborne.htm. Check with your supervisor about scheduling this vaccination series. Particular Disease Symptoms HBV is a disease of the liver. Symptoms may be non-existent or may be flu-like and, in addition, may include jaundice (characterized by a yellowing of the skin). Infection with HBV also puts an individual at risk of acquiring other liver diseases. HBV is considered to be much more infectious than HIV. The HBV virus may survive in blood up to 7 days outside the body. The 3-shot vaccine series for HBV is very safe and effective. HIV is a progressive degradation of the body’s immune system for which there is no cure or vaccine. The onset of HIV infection may yield flu-like symptoms or no symptoms at all. AIDS is the stage in HIV infection in which the body’s immune system gradually declines placing the individual at risk of various illnesses and infections. HIV survives only a few hours in dry environments. Methods of Transmission Blood is the principle infectious material and any incident in which blood is exchanged from one individual to another has the potential to result in infection. The best methods to reduce the chance of infection are to avoid high-risk behaviors such as unsafe sex, the sharing of hypodermic needles, and to use safe work practices in the workplace. This means treating all blood and bodily fluids as contaminated and handling them accordingly. All equipment and working surfaces need to be cleaned and decontaminated after contact with blood or other potentially infectious bodily fluids or materials. EHS suggests that all offices have a “blood-spill kit” available. These may be purchased through UWSP Central Stores. The kit contains plastic gloves, a towel to wipe up the spill, an antiseptic towel, and plastic disposal bag. Hands should be washed with soap and running water after contact with any potential infectious material. Exposure Control In the event of a potentially infectious exposure, clean the exposed area (hands, face, etc) immediately and notify your supervisor and either EHS, Personnel, or Protective Services. EHS will assist in determining if medical attention is necessary. If EHS is not available, proceed to Saint Michael’s emergency room (or the closest emergency room available) to determine if additional medical attention is required. Notify Protective Services at X3456 during off hours. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 6of32 For work-related exposure incidents, the exposed employee and their Supervisor must complete the following Worker’s Comp injury reports within 24 hours: “Employee’s Work Injury and Illness Report (UWS/OSLP1Emp); "Employer's First Report of Injury" form (WKC-12); and "Supervisor's Accident Analysis and Prevention" form (UWS/OSLP-2). In addition, a “Determination of Exposure to Blood/Body Fluids” (WKC8165) must be completed. Contact your supervisor or the Safety and Loss Control Department, X2618, for forms or assistance in completing the forms. Form WKC-8165 should be presented to the attending physician when seeking medical assistance. If the health care provider has an equivalent form, it may be used in place of WKC-8165. The evaluating physician should provide the employee with a written opinion within 15 days after completion of the evaluation. Contact EHS Department for assistance in obtaining this information as needed. If the attending physician determines that source testing is warranted, he/she will contact the source individual for consent. If consent is obtained, the source individual’s blood will be tested and those results will, upon consent, be made available to the exposed employee. Rules to follow: Treat all blood or potentially infectious body fluids as if they are contaminated. Stay away from the area and contact supervision to have the area cleaned properly by trained individuals (custodians). Do not clean up blood unless you are trained. If contact is unavoidable, wear personal protective equipment included in biohazard kits (available in the M&M Storeroom), and report all exposure incidents to Supervision. CONFINED SPACE ENTRY AWARENESS TRAINING This is awareness-level information regarding confined space entry. This training does not authorize any employee to enter or be involved in a confined space entry. Individuals who are actually involved in confined space entry must receive additional training on proper entry procedures. A "CONFINED SPACE" means a space that meets all of the below conditions: (1) Is large enough and so configured that an employee may bodily enter and perform assigned work; (2) Has limited or restricted means for entry or exit; and (3) Is not designed for continuous employee occupancy. Examples of confined spaces: Steam Pits, Storage Tanks, Compartments of Ships, Process Vessels, Pits, Silos, Vats, Wells, Sewers, Digesters, Degreasers, Reaction Vessels, Boilers, Ventilation & Exhaust Ducts, Furnaces, Railroad Tank Cars, Tankers (part of a Tractor-Trailer Unit), Tunnels, Underground Utility Vaults, Pipes, or Pipelines. A PERMIT-REQUIRED CONFINED SPACE is a confined space that has one or more of the following characteristics: (1) Contains or has a potential to contain a hazardous atmosphere (e.g. methane, CO, oxygen depletion, hydrogen sulfide, etc); (2) Contains a material that has the potential for engulfing an entrant (corn, water, etc); University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 7of32 (3) Has an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor which slopes downward and tapers to a smaller cross-section; or (4) Contains any other recognized serious safety or health hazard (e.g. moving parts, hazardous chemicals/materials, fall hazard, poor visibility, etc). OSHA regulates PERMIT-REQUIRED CONFINED SPACES. Permit spaces must be identified by posting danger signs at the entrance. See below for an example of a sign: Specific entry procedures must be followed when entering a permit-required confined space. (Please see http://www.uwsp.edu/ehs/policy_downloads/confined.htm for additional Confined Space information) This includes, but is not limited to: coordination with the fire department for rescue before entry, having an attendant, completing an entry permit, making the space safe for entry, locking out moving parts, relieving stored energy, atmospheric testing, ventilation, draining tanks, cleaning, wearing personal protective equipment, etc. Each person involved in a Confined Space Entry must have received specific safety training prior to entry. Entrants and attendants must also have First Aid and CPR Training. Departments are responsible for ensuring confined space procedures are developed. Contact EHS for assistance in confined space compliance. Individuals not authorized or properly trained must never enter a permit-required confined space. This includes entering a permit-required confined space to attempt a rescue. Approximately 2/3 of all individuals killed in permit-required confined space accidents are would-be rescuers. Individuals involved in confined space entry and management must attend confined space entry training provided by EHS. Call 911 for all confined space emergencies. The Stevens Point Fire Department is our designated confined space rescue provider. EMERGENCY PROCEDURES The UWSP Emergency Management Plan addresses many potential emergencies. The Plan provides detailed procedures to follow in the event of an emergency. The document is available in hard copy to key offices and areas throughout campus and is available from the UWSP homepage for the entire campus community at http://www.uwsp.edu/ehs/emp/. Go to this website and review the response steps for the emergencies listed. Click on each emergency type and read the respective procedure. Pay close attention to medical emergencies, fire/explosions, tornado/severe weather, terrorism, violent or criminal behavior, general response guidelines, evacuation procedures, and other emergencies specific to your situation. Contact your supervisor or EHS Office at 2320 with questions. When emergencies occur, you will often be advised to notify Protective Services at 3456 or, 911, especially if there is University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 8of32 a personal injury. For fires – evacuate. For tornadoes or severe weather – stay indoors and go to the lowest interior shelter away from windows. The University has also developed Building Safety Guides and Residence Hall Safety Guides for use as a quick reference to emergencies. These guides are printed pamphlets that may be stored at your desk for easier reference in an emergency. For a copy, contact EHS, at 2320. These may also be viewed at: UWSP Building Safety Guide: http://www.uwsp.edu/ehs/disasterbuilding.htm UWSP Residence Hall Safety Guide: http://www.uwsp.edu/ehs/disasterreshall.htm Chemical spills and spills of oil (used oil, diesel fuel oil, or used vegetable oil) to the environment (air, soil or river/storm sewers) must be reported to Protective Services or the Env Health & Safety Officer at 2320 and some must be reported to the WI DNR (Spill Prevention, Control, and Countermeasures’ Plan). All spills must be cleaned up. ERGONOMICS Workstation Evaluations The EHS Department offers workstation evaluations for university staff. A workstation evaluation will review the relationship of your body to your keyboard, monitor and desktop to decrease the likelihood of developing muscular skeletal disorders. The evaluator will show you proper spatial relationships and if necessary, advise you of corrective actions or products available to achieve those relationships. Evaluations are free of charge (call 4464). Additional information is available at: http://www.uwsp.edu/ehs/officeworkeval.htm. Designing a proper workstation may reduce many of the risk factors associated with Cumulative Trauma Disorder (CTDs). (Please refer to diagram). A. The Video Display Terminal (VDT) should be positioned straight on, with the top of the VDT placed at seated eye level. The recommended distance between the user and the VDT is 18 to 30 inches, about an arm’s length away. The screen should be free of glare. Allow adequate desk space for monitor depth. B. While seated, the user’s upper arms should comfortably rest at their sides, forming a 90-degree angle at the elbow. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 9of32 C. The wrist to forearm angle should be about 180 degrees. Keyboard height should be adjustable and placed at seated elbow height. Wrist rests should be padded, and the mouse pad positioned at the same level as the keyboard. D. The chair should be height adjustable, have lower lumbar back support, adjustable arms and a backward lean of 10 to 15 degrees. E. While seated, the user’s knees should be slightly elevated above the seat pan. Allow for adequate leg clearance under the work area. F. Feet should be placed securely on the floor or a foot rest for stability. G. A document holder should be placed at the same level as the VDT. Ergonomic evaluations, information, and training for other work stations (other than office) are also available for the entire campus. FIRE EXTINGUISHER SAFETY TRAINING The purpose of this training is to familiarize employees with the general principles of fire extinguisher use and the hazards involved with incipient stage fire fighting. All employees must tour their area and note the type(s) and locations of the fire extinguishers in their Departments. Used properly, a portable fire extinguisher may save lives and property by putting out small fires or containing fires until the fire department arrives. Knowing how to use a fire extinguisher is essential not only in the workplace, but also in your home. This information will help employees properly choose and use a fire extinguisher. However, hands-on training with UWSP Protective Services is required. General Information Individuals should only attempt to extinguish fires that are in the INCIPIENT STAGE (the fire is just beginning). DO NOT attempt to extinguish fires that are large or out of control. Trained individuals may only handle this type of fire. You must evacuate the area and dial 911 if a fire is beyond its incipient stage. General Fire Fighting Rules: Always call the fire department no matter how small the fire is. Never Fight a Fire that is beyond the incipient stage. Never Fight a Fire if you don't know what is burning Never Fight a Fire if the fire is spreading rapidly beyond the spot where it started Never Fight a Fire involving flammable liquids. Never Fight a Fire if you don't have adequate or appropriate equipment Never Fight a Fire if you might inhale toxic smoke Never Fight a Fire if your instincts tell you not to. Always position yourself with an exit or means of escape at your back before you attempt to use an extinguisher to put out a fire. Always inform your Supervisor. Choosing a Fire Extinguisher Fire extinguishers are tested by laboratories and labeled for the class of fire they are intended to extinguish. There are four classes of fires, A, B, C, and D. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 10of32 CLASS A: Fires in ordinary combustible materials (wood, cloth, paper, rubber, and many plastics). CLASS B: Fires in flammable or combustible liquids (i.e., gasoline, toluene, paint), flammable gases, greases, oils. CLASS C: Fires involving energized electrical equipment including wiring, fuse boxes, and circuit breakers. (NOTE: when electrical equipment is de-energized, extinguishers for Class A or B fires may be used.) CLASS D: Fires involving combustible metals, (i.e.: magnesium potassium, powered aluminum, zinc) Some portable extinguishers will put out only one class of fire, and some are suitable for two or three, but none is suitable for all four. Extinguishers must be labeled so those users may quickly identify the class of fire for which they may be used. Be sure you have the appropriate fire extinguisher for the fire you are attempting to extinguish. *WARNING* IT IS VERY DANGEROUS TO USE A CLASS “A’ RATED EXTINGUISHER ON A “C” CLASS FIRE. However, if you encounter a class “A” fire and don’t have an extinguisher with an “A” symbol, don’t hesitate to use a “B” or “C” extinguisher. Then follow-up with a class “A” extinguisher. Using the Fire Extinguisher When using a fire extinguisher always keep your back to an exit and stand twelve feet away from the fire. Follow the four-step PASS procedure. If the fire does not go out immediately, leave the area at once. Pull the pin OR Push Puncture Lever: Aim low This unlocks the operating lever and allows you to use the extinguisher. Some extinguishers will have a pin and some will have a puncture lever. Follow instructions on your specific fire extinguisher. Point the extinguisher nozzle (or hose) at the base of the fire. Stand 10 feet away from fire. Squeeze the operating lever This will discharge the extinguishing agent. Sweep Keep the extinguisher aimed at the base of the fire and sweep back and forth until the flames appear to be out. All fire extinguishers must be clearly marked with operating instructions. Operating instructions will vary from one type of extinguisher to the next. If an extinguisher has been discharged or damaged for any reason, report it to UWSP Facility Services. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 11of32 PIN Type Fire Extinguishers Remember: When in doubt around any fire, evacuate immediately, close off the area, and call 911. Avoid exposure to smoke and fumes. Those individuals expected or likely to utilize a fire extinguisher are to attend fire extinguisher training offered by UWSP Protective Services Department (call 3456). University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 12of32 HAZARD COMMUNICATION All supervisors must provide their employees with the information and training covering the hazards of chemicals to which they may be exposed and the means to avoid those hazards as required by Occupational Safety and Health Administration’s (OSHA) hazard communication standard (29CFR1910.1200). The following information provides the basics of hazard communication. Department-specific training on particular chemicals is to be provided by the supervisor. Contact EHS for assistance. Additional on-line training is available on the UWSP EHS Website at: https://uwsystem.courses.wisconsin.edu/. To complete the on-line training for Hazard Communication, contact the EHS Officer at 2320 for assistance. Contact EHS Department for assistance in all areas of hazard communication compliance. See the UWSP Right-to-Know Policy at http://www.uwsp.edu/ehs/policy_downloads/rtkhcp%207-06.doc for further details. All individuals must know the hazards and proper personal protective measures required for each chemical prior to starting a job involving the hazardous chemicals. Always review MSDS and speak to department supervisor prior to working with unfamiliar chemicals. What is a Hazardous Material / Substance? According to the OSHA Hazard Communication Standard, a hazardous chemical is any element, chemical compound, or mixture of elements or compounds, which is a physical or health hazard. A hazardous substance is any material or mixture that contains properties capable of producing adverse effects on the health and/or safety of humans. Substances are considered either health hazards or physical hazards. Health Hazards A chemical is considered a health hazard if it causes acute or chronic health effects in employees who have been exposed. The best protection against overexposure is to keep chemicals from entering the body. If a chemical can not enter the body it can not harm the body. Knowing how hazardous chemicals enter the body helps to understand the measures needed to prevent chemicals from doing so. There are four primary routes of exposure by which hazardous chemicals may enter the body: INHALATION - Toxic fumes, vapors, and dust may enter through the nose, pass through the lungs, and enter the bloodstream to circulate through the body. ABSORPTION - Many toxic substances may be absorbed through exposed skin. Chemicals may enter the body through cuts and wounds as well. INGESTION - Eating, smoking, applying makeup, or accidentally contacting the lips/mouth while there is a hazardous substance on the hands/fingers, the substance may enter the body through the mouth. INJECTION – Needle sticks, punctures, etc. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 13of32 Acute health effects – severe symptoms which develop immediately after exposure. Some examples are nausea, dizziness, headaches, burns, and unconsciousness. Chronic health effects – symptoms that develop slowly over a long period of time or that occur frequently. Some examples are allergic sensitization skin problems, respiratory disease, and existing medical conditions that are aggravated by exposure to a chemical. Definitions of some health hazards: Irritants – are chemicals that cause intense redness or swelling at the point of contact with body tissue. Sensitizers – are substances that cause allergic reaction in a majority of people after repeated exposure. Corrosives – are chemicals that may cause tissue damage at the point of contact. Target organ effects – are caused by chemicals that effect body organs such as the liver, kidney, and central nervous system. Toxic substances – are chemicals that are proven to cause death in animals and man at moderate to low doses. Reproductive toxins – are chemicals that may cause birth defects or sterility. Carcinogens – are substances capable of causing cancer. Physical Hazards A chemical is considered a physical hazard if it has the potential, when released, mixed with other chemicals, and/or by itself, to create a hazardous condition. Definitions of some physical hazards include: Flammable liquids – are liquids that will readily ignite in the presence of heat, sparks, and/or flame. Flammable liquids have a flash point below 1000F. Combustible liquids – are liquids that are not easily ignitable as flammable liquids. Combustible liquids have a flash point at or above 1000F. Pyrophoric – chemicals that will spontaneously burst into flame at temperatures lower than 1300F. Oxidizers – are materials that readily release oxygen, which may cause combustible materials to burn on contact or accelerate burning. Organic peroxides – are a special chemical family that act as powerful oxidizers. Explosive – chemicals that cause a sudden release of energy which includes a release of pressure, gas, and heat when subjected to shock, pressure, or heat. Water reactive – chemicals that will react with water to release a gas which is either flammable or presents a health hazard. Unstable – materials are self reactive under certain conditions such as shock, pressure, or temperature. Compressed gases – are materials stored under pressure but are released as a gas for use. Material Safety Data Sheets (MSDS) The Occupational Safety and Health Administration (OSHA) (29CFR1910.1200) require that employees be informed about chemical hazards in their workplace. The MSDS provides hazardous chemical information for a given product. MSDSs are available to employees for all hazardous chemicals or products used at UWSP. MSDSs are required to be in English and are to be developed and supplied by the chemical manufacturer, and available for review by employees. Individual departments are to keep a folder of all relevant MSDSs within their department. Many MSDSs are available on-line at: http://ccinfoweb.ccohs.ca/msds/search.html. See the UWSP EHS website for additional on-line resources: http://www.uwsp.edu/ehs/index.htm under MSDS. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 14of32 While OSHA does not specify the format of MSDSs, it does require certain specific information. There are eight basic required categories of information required on the MSDS. All required sections must be covered. If the required information is not available or not applicable, this must be indicated on the form. Additionally, if the ingredients of a chemical mixture are trade secrets, the identity may be withheld but the hazardous properties must be given. All MSDSs must contain, at least, the following information: The identity used on the container label and if it is a single substance or mixture. Physical and chemical characteristics. The physical and health hazards of the product. Primary routes of entry. The OSHA Permissible exposure Limit (PEL), ACGIH Threshold Limit Value (TLV), and any other exposure limit used or recommended by the manufacturer. Whether the hazardous chemical is listed in the National Toxicology Program (NTP) Annual Report on Carcinogens or if it has been found to be a potential carcinogen. Applicable precautions for the safe handing and use. Any applicable control measures (engineering, work practices, PPE) Emergency and first aid procedures. The date of preparation or last revision date. The name, address, and telephone number of the chemical manufacturer, importer, or other responsible party preparing or distributing the MSDS who will provide additional information on the hazardous chemical. MSDSs must be made readily available to employees during normal work hours. MSDSs may be obtained through immediate supervisors, on the internet: http://ccinfoweb.ccohs.ca/msds/search.html, or in the EHS Officer’s file in 101 Geo. Stien Bldg. MASTER FILES: The UWSP EHS Department maintains a master file of MSDS sheets at UWSP. SUB-FILES: Each Department is responsible to maintain a MSDS file for all hazardous chemicals found in their department and send a copy to EHS. Contact your Supervisor for the location of MSDS sheets in your department. Chemical Inventory / Hazard Review Chemicals purchased by UWSP Departments should be reviewed by the purchaser, for safety and environmental concerns and approved for use by the department head or delegated individual. EHS department is available for assistance in this process. An inventory of chemicals used in your workplace needs to be completed by the department and forwarded to the Environmental Health and Safety Department. Copies of the departmental inventory should be placed in Appendix B of the Employee Right to Know Policy in the UWSP Health and Safety Manual. An annual update inventory should be performed. Labels All containers are to be labeled at UWSP. Containers that hold non-hazardous substances are to be labeled to avoid confusion. OSHA requires each container of hazardous substances to be identified. The manufacturer’s label must not be removed. Each container of hazardous chemicals in the workplace must be labeled, tagged or marked to identify the hazardous chemical(s) contained and provide appropriate hazard warnings (words, signs, etc.). Chemicals coming into and/or leaving the workplace must also have the name of the manufacturer University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 15of32 of the material (manufacturer’s responsibility). If chemicals are transferred or mixed from the manufacturer’s containers into a secondary container, the secondary container must be labeled with product identity and appropriate hazard warning for all chemicals involved. The only exception to this that one is not required to label portable containers into which chemicals are transferred from labeled containers, and which are intended only for the immediate use of the employee who performs the transfer. Note that labels coming into the workplace may have different labeling formats or symbols that provide similar information. If the manufacturer’s label is missing or if some of the product has been transferred to a secondary container, use the HMIG labeling system available from your supervisor. Labels are the first source of information about hazardous materials employees should use to determine the extent of the hazard(s). Employees should first carefully read the chemical container label before using the product. Below is an explanation on the NFPA labeling system and HMIG labeling system. HMIG labels are utilized by the UWSP EHS Department. The National Fire Protection Association Labeling System (NFPA): General Rating Summary Health (Blue) 4 - Danger - May be fatal on short exposure. Specialized protective equipment required 3 - Warning - Corrosive or toxic. Avoid skin contact or inhalation 2 - Warning - May be harmful if inhaled or absorbed 1 - Caution - May be irritating 0 - No unusual hazard Flammability (Red) 4 - Danger - Flammable gas or extremely flammable liquid 3 - Warning - Flammable liquid flash point below 100° F 2 - Caution - Combustible liquid flash point of 100° to 200° F 1 - Combustible if heated University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 16of32 0 - Not combustible Reactivity (Yellow) 4 - Danger - Explosive material at room temperature 3 - Danger - May be explosive if shocked, heated under confinement or mixed with water 2 - Warning - Unstable or may react violently if mixed with water 1 - Caution - May react if heated or mixed with water but not violently 0 - Stable - Not reactive when mixed with water Special Notice Key (White) W - Water Reactive ACID – Acid W – Use no Water OXY - Oxidizing Agent ALK – Alkali COR – Corrosive P- subject to polymerization when mixed with water - Radiation Other Special Symbols The following are special precaution symbols which may be found in addition to the NFPA chemical hazard diamond. Flammable! Explosive! Corrosive! Poison! Compressed Gas! Hazardous Materials’ Identification Guide The HMIG labeling system operates on the same principle as the NFPA diamond. Blue indicates health hazard, red indicates flammability, yellow indicates reactivity, and special information (such as what personal protective equipment to wear) will be provided in the white section. It also uses a numerical system from 0-4 to indicate the severity of the hazard. The HMIG labeling system is similar to the HMIS labeling system. These labels should be used on individual containers of hazardous materials (i.e. barrels, bottles, cans, buckets, tubs, etc) so that there are never any unlabeled containers in the work area. It is recommended that they be used on all containers, even if the manufacturer's label is still in place; however, this is just a recommendation. Always regard unlabeled containers as dangerous! If a product or chemical is transferred from its original container into another container that doesn't have a manufacturer's label, the second container must be labeled with an HMIG label with the appropriate information filled out. HMIG labels are available in a variety of sizes from the EHS department. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 17of32 HMIG Label Key to HMIG Label Numerical Ratings HEALTH: 4 – Extreme: Highly Toxic. May be fatal on short-term exposure. Special protective equipment required. 3 – Serious: Toxic. Avoid inhalation or skin contact. 2 – Moderate: Moderately Toxic. May be harmful if inhaled or absorbed. 1 – Slight: Slightly Toxic. May cause slight irritation. 0 – Minimal: All chemicals have some degree of toxicity. FLAMMABILITY: 4 – Extreme: Extremely flammable gas or liquid. Flash Point below 73ºF. 3 – Serious: Flammable. Flash Point 73°F to 100ºF. 2 – Moderate: Combustible. Requires moderate heating to ignite. Flash Point 100°F to 200ºF. 1 – Slight: Slightly Combustible. Requires strong heating to ignite. 0 – Minimal: Will not burn under normal conditions. REACTIVITY: 4 – Extreme: Explosive at room temperature. 3 – Serious: May explode if shocked, heated under confinement or mixed with water. 2 – Moderate: Unstable. May react with water. 1 – Slight: May react if heated or mixed with water. 0 – Minimal: Normally stable. Does not react with water. SPECIFIC: Protective Equipment to be used A - safety eyewear B - safety eyewear and gloves C - safety eyewear, gloves and apron D - eye and face protection, gloves and apron E - safety eyewear, gloves and dust/mist respirator F - safety eyewear, gloves, apron and dust/mist respirator G - safety eyewear, gloves, and vapor respirator University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 18of32 H - safety eyewear, gloves, apron and vapor respirator I - safety eyewear, gloves and dust and vapor respirator J - safety eyewear, gloves, apron and dust and vapor respirator K - supplied-air respirator, gloves, full suit and boots X - Ask your supervisor for special handling instructions Haz Com Safe Work Practices Whenever working with hazardous chemicals, follow this list of general recommendations: Personal Hygiene / Personal Protection Keep work area and tools clean. Wear recommended PPE. Keep work clothing clean, inspect it regularly for holes/tears, and never mix them with home laundry. When working with chemicals, never wear sandals, shorts, or other clothing which will expose more skin than necessary. Remove all jewelry before beginning work. Do not wear contact lenses while working in or around chemical vapors without protective goggles. Never deliberately smell or taste hazardous chemicals. Wash hands often, especially before smoking, eating, applying makeup or drinking: and after completing work and at the end of the day. Smoke, eat, and drink only in designated areas. Procedures Read warning signs, labels, and MSDSs before the start of work. Know the hazards. Plan the work in advance and know what to do in case of spill, fire, or exposure to hazardous chemicals. Follow the work rules established by supervisors. Do not take shortcuts. If possible, try not to work alone. Always stay alert and focused on the task at hand. Watch for hazardous situations and signs of trouble such as unusual sounds/odors. (NOTE - Odor is an unreliable source for the presence of a chemical. The sense of smell gets fatigued quickly and a hazardous situation may seem less serious. Never perform a task not authorized to perform. Never use mouth suction to fill a pipette, use a pipette bulb or other filling devise. Use the smallest amount of chemical necessary to perform the task. Always use chemicals as directed (properly diluted) and for the intended purpose. Ensure adequate ventilation. Use caution while moving chemical containers. Check for leaks in hoses, tanks, cans, and other chemical containers. Always keep chemical containers closed when not in use. Storage and Cleanup Close lids and caps tightly before storing chemical containers. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 19of32 Store chemical containers according to the hazard classifications. Be sure not to store incompatible materials next to each other. Do not store chemicals in aisles, exits, or in front of stairways. Never store flammable or combustible materials near a heat source. Never store liquids above eye level. Store especially hazardous materials (carcinogenic) in secondary containers (one inside the other). Always follow local, state, and/or Federal regulations for disposing chemicals and contaminated materials. HAZARDOUS MATERIALS – (DOT HAZMAT) A Hazardous Material (HAZMAT) is a substance or material that has been determined to be capable of posing an unreasonable risk to health, safety, and property when transported in commerce. A HAZMAT employee is one who loads, unloads or handles hazardous materials and who works for a HAZMAT Employer. All HAZMAT Employees are to be trained: so they are familiar with the requirements of the Department of Transportation regulations regarding shipment of hazardous materials; so they are able to recognize and identify hazardous materials; and so they are able to respond to emergencies. Documentation is necessary; contact EHS at 2320 for training assistance. The DOT requires proper labeling, placarding, and shipping papers for any hazardous material offered for transportation in commerce to prevent spills and exposures or injuries due to hazardous materials. Hazardous materials are identified by labels on the drums or packages and placards on the trucks hauling them. There are 9 classes of hazardous materials: 1 - explosives; 2 - gases; 3 - flammable liquids; 4 - flammable solids; 5 oxidizers; 6 - poisons; 7 - radioactives; 8 - corrosives; and 9 - miscellaneous hazardous materials (such as asbestos). In order to work safely with hazardous materials, read the label, refer to the Material Safety Data Sheet for advice on proper personal protective equipment and to become familiar with compatibilities and response to spills, and ask supervision about proper handling. HAZARDOUS WASTE UWSP is a Large Quantity Generator of Hazardous Waste. We generate wastes that are toxic, corrosive, reactive, and/or combustible, besides other chemicals that are specifically listed as hazardous wastes. Hazardous Wastes are generated within many departments at UWSP. Training is available for everyone on campus at: http://www.uwsp.edu/ehs/hazwastetraining1.htm or by contacting EHS at 2320. Any employee involved in the generation, disposal or management of hazardous waste is required to have annual training. Hazardous Waste must be identified properly; labeling and storing must be done by properly trained personnel. Shipments of Hazardous Wastes are made quarterly. Persons handling hazardous waste must know how to respond to emergencies (ie: spills & fires). Questions about wastes may be directed to lab supervisors or the EHS Officer at 2320. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 20of32 HOISTING EQUIPMENT Individuals must receive specific training from their department prior to using hoisting equipment. Equipment used to lift product must be closely inspected. This includes, but is not limited to inspection of the ropes, slings, chains, controls, hooks, stops, tracks, etc. Overhead cranes and hoists must be inspected each day. NEVER use defective product or equipment and never walk beneath a suspended load. Stop work and report to Supervisor with any questions. HOUSEKEEPING Many injuries may be avoided by keeping the work area clean and clutter-free. Keep your work area neat, keep rugs from overlapping, buckling or being folded back at the corners, have adequate lighting, avoid tripping hazards such as extension cords or hoses or open drawers, and clean up spills to avoid slippery surfaces. Avoid bad habits and unsafe work habits; clean up after yourself. Some examples include: Keep your work area clean! Keep all scrap, hoses, cables, trash, waste and other materials clear of walkways and in the proper location/container. EACH PERSON IS RESPONSIBLE FOR HOUSEKEEPING OF THEIR WORK AREA. Materials must be safely stacked and stored at all times. Inspect storage equipment before use. All waste materials, paper, scrap food, etc. shall be placed in proper containers. Clean up all grease, oil or other spills immediately; all oil spills must be cleaned up. Report all spills immediately to your supervisor. Keep materials and equipment clear of designated walkways or passageways at all times. Do not leave scrap steel, tools, or trash on staging or in mechanical lifts or aerial buckets and platforms. Remove these materials as soon as possible and before the end of your shift. Do not store any material in, on, near, or in front of electrical switch boxes, switchboards, circuit boxes, or distribution stations. Access to exits, fixed ladders, stairways, gas and water valves, fire-fighting equipment, rescue or other emergency equipment shall not be obstructed. Projecting nails are dangerous. Remove, re-drive, or bend them over whenever found. Keep lockers clean and do not store any flammables in them. Flammable liquids must be stored in a designated storage cabinet or room. LADDER SAFETY/FALL PROTECTION Ladders must be inspected before use; unsafe ladders must be removed from service and repaired before use. Ladder feet must be non-skid and in good condition. A fall of sixteen feet only takes one second. In 2002, falls accounted for 15,400 deaths in the USA. A 220 lb body, falling 6 feet, results in forces of 3000 to 5000 lbs when the body hits the ground. Be very careful to avoid slippery surfaces on the ground and on the steps of the ladder being used. Do not use makeshift ladders. The top two rungs of stepladders must not be used to stand on. Ladders must not be moved while a person is on the ladder. Ladders may only be used vertically, never horizontally. A straight ladder must be extended one foot out from the vertical for every four feet of length (a 12’ ladder must be extended from the base 3’ from the vertical). Workers must maintain a three-point contact with the University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 21of32 ladder at all times, keep the belt buckle within the railings. When extended above the roof-line, the extension ladder must extend at least 3 feet above the roof edge. Full-Body harnesses with lanyards must be worn when working off mechanical scaffolds, incomplete staging, or any time there is a chance of falling more than six (6) feet. Alternative fall protection devices must be approved by the Environmental, Health, & Safety Officer. A full-bodied harness with lanyard attached to the platform or boom strap must be worn by each individual working in an aerial bucket (Jig-Type Lifts). Harnesses with lanyards are not required for scissors lifts provided all railings are intact, gates are closed, chains are attached and occupants’ feet remain on the platform. It is very important that lanyards and harnesses are inspected PRIOR TO EACH USE. LEAD AWARENESS The University of Wisconsin Stevens Point (UWSP) will conduct routine lead exposure assessments prior to construction activities to determine if any employee may be exposed to lead at or above the action level. Proper work practices will be determined and hazard communications will be initiated as required from the lead exposure assessment. Supervisors are responsible for ensuring these practices within their area of responsibility. Window with lead paint in poor condition. Lead: • Is a naturally occurring metallic element found in the earth’s crust. Lead may be found in many parts of the environment including water/soil. • Is/Was used in paints, gasoline, ceramics, pipes, ammunition, batteries, radiation shielding, glass, etc. However, use has been reduced over the years. • Is highly resistive to corrosion thus was utilized widely in the past. • Is hazardous to humans through ingestion and inhalation (dusts/fumes). It enters the bloodstream, where it is distributed to all tissues of the body; it affects organs (i.e. kidneys), central nervous system, and reproductive system. It decreases reaction time, causes weakness, results in memory loss, blood University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 22of32 • • • • • • • disorders, brain disorders (learning difficulties), interferes with normal growth, and hearing problems, etc. It affects children more than adults. Permissible exposure limit (PEL) - 50 micrograms per cubic meter of air (50 ug/m3) 8-hour time weighted average. 30 micrograms per cubic meter of air or greater, then employer must offer employees routine blood testing. Community requirements – Air may not exceed 1.5 micrograms/m3. Drinking water < 15 ug per L. Consumer Products Safety Commission banned use of lead in commercial paint (>.06%) - 1978. Clean air act banned sale of leaded gasoline 1990. Care must be used around lead as it is a cumulative poison. Old paint is the largest lead concern on UWSP campus. Sanding and scraping lead paint could cause exposure. Heating and cutting of lead pipes could also create exposure. Proper safety precautions must be taken prior to working on areas containing lead that will be reviewed with affected employees. If unsure if area contains lead, contact EHS to have tested prior to working on it. An abatement company may be contracted to remove materials containing lead as necessary. Lead testing surveys have been completed in the following UWSP buildings: Delzell, HEC, Science, LRC, FAC, CPS, and CNR. Lead Waste disposal – contact EHS at 2320. LOCKOUT/TAGOUT AWARENESS TRAINING Many occupational accidents are caused by the uncontrolled release of hazardous energy from machines and equipment. Most of these accidents may be prevented by the use of proper lockout/tagout procedures. The purpose of this session is to inform Affected and Other employees of lockout/tagout requirements so that accidents will be prevented. This awareness training is designated for individuals who fall under the following OSHA definitions: Authorized Employee = A person who locks-out or tags-out machines or equipment in order to perform servicing or maintenance on that machine or equipment. Affected Employee = An employee whose job requires him/her to operate or use a machine or equipment on which servicing or maintenance is being performed under lockout or tagout, or whose job requires him/her to work in an area in which such servicing or maintenance is being performed. Other Employee = Employees who are neither “Authorized” nor “Affected”, but who work in areas where Lockout/Tagout activities take place. NOTE: Authorized Employees are required to have additional training which details recognition of applicable hazardous energy sources, the type and magnitude of the energy available in the workplace, and the methods and means necessary for energy isolation and control. ONLY TRAINED AUTHORIZED EMPLOYEES ARE ALLOWED TO PERFORM ACTUAL LOCKOUT/TAGOUT. What Is Lockout/Tagout? A lockout is a method of keeping equipment from being set in motion and endangering workers. It’s putting equipment into a temporary condition in which all power and/or energy is de-energized or blocked. This is called the zero mechanical state (ZMS). Basics of Lockout/Tagout include: Placing the Energy Isolating Device (disconnect switch, circuit breaker, valve, or other energy isolating device) in the safe or off position. Attaching a lock to the Energy Isolating Device so that the Energy Isolating Device is secured in the off or safe position. This prevents the equipment from being energized. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 23of32 Attaching a tag or a sign on or near the Energy Isolating Device that warns against operating the equipment or machinery. Ensuring all stored energy is relieved or made safe. Communication between authorized and/or affected employees at all stages of the process. Safe start-up procedures. When Should Lockout/Tagout Take Place? Lockout/Tagout is required whenever service, clean-up, or maintenance is being performed around any machine where an employee could be injured by unexpected startup of the equipment or release of stored energy. Lock out/Tagout is also required in certain situations involving the removal of guards, work at the point of operation, and shut down of broken equipment. What Is Hazardous Energy? Some types of hazardous energy are electricity, pressurized hydraulic fluid, pneumatic, chemical, thermal, and certain types of stored energy such as spring force and gravity. To protect employees from injuries, locking type devices with warning tags are used to keep the Energy Isolating Device in the “off” or “safe” position. Below is an example of a Lockout and Tagout device: The lock is the isolation device used to prevent a machine from operating and/or prevent energy from being released during maintenance, servicing, or clean up. The tag is the visual indicator for lockout that includes the name of the person responsible for the locked out condition. Remember: Do not attempt to operate any switch, valve or other energy isolation device that is locked and/or tagged out. Do not remove a lock or tag on a machine or piece of equipment that is locked/tagged out. All affected employees are to be notified when a lockout will begin and end on equipment applicable to their position. Never tamper with lockout/tagout devices and never attempt to operate any machines that have these devices on them. To do so may endanger your life and the lives of those who are performing work on the machines. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 24of32 MANUAL LIFTING SAFETY Things You Can Do On The Job Never attempt any lifting until your body is warm and loose. Perform some simple stretching and warm-up exercises if necessary. Do not attempt to lift heavy or bulky items alone. Depending on your job, get assistance if the load is too heavy. Get assistance from another person or material-handling equipment (cart, pallet truck, forklift, hoist, crane, etc). Reduce the amount of weight lifted. For example, if you're moving a bunch of books, better to load several small boxes than one extremely heavy load. Use handles and lifting straps whenever possible. Pushing the object is safer than pulling it to the desired location. Store materials at least 12 inches off the ground, where possible, this minimizes the danger of one of the most hazardous movements -- lifting directly from the ground. Avoid lifting in a situation where the body will be twisted. Avoid jerking or erratic motions. Never try to catch heavy falling objects. Techniques The human back operates on a 10:1 ratio. Bending over to lift a ten-pound object actually puts 100 pounds of pressure on your lower back. When you add in the 105 pounds of the average human upper torso, you see that lifting a ten-pound object actually puts 1,050 pounds of pressure on the lower back. Proper Lifting Procedures You can't avoid lifting, but there are ways to reduce the amount of pressure placed on the back. By bending the knees, you keep your spine in a better alignment, and you essentially take away the lever principle forces. Instead of using your back like a crane, you allow your legs to do the work. Follow these steps when lifting: 1. Take a balanced stance with your feet about a shoulder-width apart. One foot can be behind the object and the other next to it. Keep the back straight to keep the spine, back muscles, and inner organs in correct alignment. This will minimize the chance of a hernia. 2. Squat down to lift the object, but keep your heels off the floor. Grip the object with the whole hand for more lifting power. Center your body over your feet for balance and lifting power. Get as close to the object as you can. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 25of32 3. Use your palms (not just your fingers) to get a secure grip on the load. Make sure you'll be able to maintain a hold on the object without switching your grip later. 4. Lift gradually (without jerking) using your leg, abdominal and buttock muscles and keeping the load as close to you as possible. Keep your chin tucked in so as to keep a relatively straight back and neckline. Bend your legs and then lift the object by straightening the legs. Your leg muscles will now take the load instead of your back. 5. Once you're standing, change directions by pointing your feet in the direction you want to go and turning your whole body. Avoid twisting at your waist while carrying a load. Reduce overhead reaching. When you put a load down, use these same guidelines in reverse. Other Helpful Lifting Advice Follow a regular exercise program but see a doctor before starting an exercise program for a checkup and advice. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 26of32 Some sports are excellent conditioning for the back. Swimming, cycling, walking, and rowing are considered to be good for the back. Golf, bowling, racquet sports, football, baseball and weight lifting are more likely to cause back injury because they involve more rapid start and stop movements, twists, and turns. Maintain a good posture. Poor posture is another contributing factor. When your mother told you to sit and stand up straight, she was giving you good advice. It is best to try to maintain the back in its natural "S" shaped curve. You want to avoid leaning forward (unsupported) when you sit, or hunching over while you're standing. Do not sit or stand too long in one position – take short breaks. Avoid wet or slippery floors. Falls are a common cause of back injury. Maintain a reasonable weight. Extra weight may be a big problem. Remember the fulcrum / lever principle? The more you weigh, the more stress it puts on your back every time you bend over... on a 10:1 ratio. Stop smoking and Reduce Stress - Tense muscles are more susceptible to strains and spasms. Overdoing it – Ask yourself, "Is this too heavy for me to lift alone?" It's important to recognize your own physical limitations. Many people have injured their backs because they were reluctant to ask for help. PERSONAL PROTECTIVE EQUIPMENT (PPE) When possible, safety hazards at UW-Stevens Point will be eliminated or guarded through the use of engineering and/or administrative controls. Personal protective equipment (PPE) will be used to supplement these efforts and further ensure employee safety as necessary. PPE includes: safety glasses/goggles, gloves, coveralls, safety shoes with steel toe guards, hearing protection, face shields, hard hats, fall protection, respirators, gloves, aprons, etc. All personal protective equipment has limitations. A requirement to use a particular form of PPE in a certain area of the University may be based on one or more considerations. It may be the result of a safety or hazard assessment that indicated the need. It also could be the result of having performed exposure monitoring, MSDS recommendation, or it might be required by an OSHA regulation. In any case, when PPE is specified, it is for the employee’s protection and therefore its use is mandatory. Failure to wear PPE may result in injury. Four of the most basic types of PPE are safety shoes, safety glasses with side-shields, hearing protection, and gloves. Safety shoes are required for employees in certain job classifications. Your supervisor will inform you if they are required on your job. A yearly allowance is paid through a separate check each January. Safety shoes may be purchased from any source. EYE PROTECTION - SAFETY GLASSES/GOGGLES: Safety glasses with side shields protect your eyes from impact with foreign bodies (e.g., chips, sparks, etc.). They offer only limited protection against chemical mists or splashes. Goggles/face shield should be worn when working with hazardous chemicals. HEARING PROTECTION: Hearing protection protects against loss of hearing from occupational noise exposure. The use of earplugs or earmuffs is extremely important in guarding against chronic noise. Hearing loss occurs over time and is often not recognized for many years. Several types of earplugs are available. Hearing protection is highly recommended whenever 85 dBA or more are encountered. HAND PROTECTION: Wearing gloves is encouraged to protect against burns, cuts, and abrasions, as needed. Chemical or solvent-resistant gloves are available for some positions such as painters. Other SAFETY SHOES: University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 27of32 times gloves may be required include: cold weather, live electrical work, ergonomic considerations (such as vibration), and abrasion/laceration resistant. Do not wear gloves near moving machine parts or materials. JEWELRY/NECKTIES/HAIR: Be careful of jewelry, neckties, or long hair around moving equipment. RESPIRATORS: Respirators are available for certain positions or on an as-needed basis (painters, working with chemicals or hazardous waste, or in a dusty environment). Contact the EHS Officer at 2320 for more information and respirator use requirements. OTHER PPE: Other PPE may be required depending on your job. For example, face shields, welding helmets, shaded glasses, respirators, chemical goggles, aprons, fall protection, hardhats, and other PPE are required for various jobs at UWSP. See your Supervisor for PPE supplies and details on unique PPE requirements in your Department. The following guidelines should be followed when wearing any PPE: • • • • • • Inspect PPE everyday before using. Replace worn-out PPE. Make sure you are using the PPE correctly (get the proper training from area supervisors ie: donning, doffing, adjusting, cleaning, maintaining, storing, and disposal). Do not try to make repairs yourself; and, most importantly, do not rely on defective equipment. See your Supervisor immediately if you have problems with any PPE. Make sure all PPE fits well and is approved for that particular use or set of conditions. Each UWSP employee, regardless of position, is responsible for using PPE where required. All supervisors have the responsibility to ensure proper PPE use and training in their area(s) of responsibility. Contact EHS for assistance in PPE evaluation and selection. REMEMBER: WEAR PERSONAL PROTECTIVE EQUIPMENT TO GUARD YOURSELF FROM INJURY. IT IS EFFECTIVE ONLY WHEN WORN AND USED PROPERLY. POWERED INDUSTRIAL VEHICLES Separate training classes are required for those who will need to operate forklifts, aerial lifts, Powered Platforms, vehicle mounted work platforms and other specialized equipment. This will include information on liquefied petroleum (LP) gas used for power. Pedestrians: Keep a close watch while walking on campus for powered vehicle traffic! DO NOT pass beneath suspended loads of any kind. Stay clear of any industrial vehicles. TORNADO/SEVERE WEATHER RESPONSE Tornado/Severe Weather Information Severe weather may occur throughout each season in the Stevens Point region. Tornados have been documented in Wisconsin in every month except January. Other potential severe storms include University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 28of32 thunderstorms, high wind, ice, hail, snow, blizzard, and rain. See National Weather Service website http://weather.noaa.gov/weather/current/KSTE.html for detailed weather information (additional sites referenced below). See UWSP Emergency Management Plan at http://www.uwsp.edu/ehs/emp/ under Tornado/Severe Weather for further details on emergency response. Severe Weather Response Guidelines: 1. General Severe Weather Response: Stay away from windows and exterior doors during all severe weather. Notification of an approaching dangerous storm will be made by: a. County sirens will sound in the event of a tornado warning. b. The National Weather Service and Emergency Alert System via the broadcast media, weather radios, and email alerts (you must sign-up for). If conditions are present for possible severe weather formation, you must monitor and keep aware of severe weather possibilities. Always be prepared to take action. c. For tornado warnings, UWSP Protective Services will announce via public address systems in buildings equipped with voice-capable warning systems and in person in certain areas when possible. Recipients of warnings must quickly disseminate weather information throughout their areas. This may be in the form of a phone tree or by walking through the area and verbally spreading the word. 2. Tornado Watch Response Tornado watch means that weather conditions are favorable for the formation of a tornado, but that no tornado has actually been sighted. Monitor the local media, weather radios, and weather Internet sites for weather updates and be alert to changing weather conditions. Be prepared to take action if the weather situation is upgraded to a tornado warning. 3. Tornado Warning Response a. If Portage County sirens sound or tornado warning is issued, building occupants should take shelter in the lowest level interior room without window exposure - preferably in a basement. b. See building floor plans online at http://www.uwsp.edu/ehs/FLOORPLANS.htm for shelter locations at UWSP. The severe weather shelter locations are also located on the UWSP EMP website under “Severe Weather”. c. Shield yourself as well as possible by seeking shelter under sturdy objects, duck and cover your head with your arms, or by other available means. If you are unable to get to the lowest area, go to an interior room or stairwell away from windows and exterior doors. Avoid wide-span structures such as gyms, pools, or large classrooms. d. If for some reason you are unable to flee to a safer area, get under a desk, heavy table, or other object that could shield you from flying debris. e. Remain in your shelter area until instructed to do otherwise by National Weather Service broadcasts, weather radio, department management, or Protective Services. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 29of32 f. Keep a flashlight, battery-operated weather or other radio, and cell phone to take to the shelter area. g. If driving, park your car and seek shelter away from the car in a nearby ditch or ravine. Avoid areas with power lines, poles or signs. Never try to outrun a funnel cloud or tornado in a vehicle. h. After a tornado, watch for secondary hazards such as electrical wires and other dangerous wreckage. If surrounded by debris, be aware that moving it may cause other debris or part of the building to collapse. If it is not safe or possible to leave the area, stay there until assisted out. 4. Severe Thunderstorm Response a. Severe thunderstorm warning notifications will be made by NOAA Weather Radios and local broadcast media. b. Notify affected individuals and discontinue exterior work that may place persons in danger of the immediate storm. c. Seek interior shelter away from windows and exterior doors and close blinds and drapes. d. If conditions worsen, individuals may be advised to move to the designated storm shelters as discussed above in the Tornado Warning section. 5. Ice/Sleet/Snow Response a. Notification of a severe ice/sleet/snow storm will be made by the same sources mentioned above. b. Refer to the UWSP Inclement Weather Policy, which may be obtained from the Personnel Office at X2606. c. Exercise caution on outdoor walkways and while driving. Notify Grounds’ Maintenance at 4219 or 3622 to report icy sidewalks. See the EHS Website under “Severe Weather” for additional resources on severe weather. OTHER INFORMATION Smoking: NO smoking or tobacco products are allowed in University Buildings! Never smoke near flammable materials. Do not litter areas with butts. Smoking in unauthorized areas is not allowed. See building floor plans for designated smoking areas outside the buildings: http://www.uwsp.edu/ehs/FLOORPLANS.htm. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 30of32 Outside Contractors: New outside contractors should attend a safety orientation before beginning work presented by the Project Manager or designee. All safety and health requirements must be met by the contractor and they are responsible for compliance. Crosswalks: Use crosswalks. They are there for your safety. Other Training: There are other job-specific training programs required for various positions. Much of this information is awareness-level training. Full courses in specific topics (e.g. confined space, lockout/tagout, etc.) may be required depending on one’s job duties. Supervisors are to contact EHS (2320) for assistance in determining their department’s training requirements. Recycling and Trash Collection: Jugs or bottles for recycling or trash must have caps removed and be thoroughly rinsed (triple-rinsed) and dry before the recycling crew will take them. http://www.uwsp.edu/facserv/recycling/chemical%20bottles.htm Broken glass must be in boxes or, preferably, pails labeled “broken glass” and must not be in plastic bags. http://www.uwsp.edu/facserv/recycling/broken%20glass.htm; http://www.uwsp.edu/facserv/recycling/fluorescent.htm Metal wire for disposal or recycling must be in boxes or pails; not in plastic bags. The recycling supervisor will be notified if the recycling crew leaves jugs or broken glass at a dock. The EHS Officer will then be notified. Reminders concerning recycling requirements must be sent out each semester due to turn-over of personnel. We expect everyone to follow these procedures to avoid injuries. Everyone’s cooperation is very much appreciated. All Employees: Everyone is expected to: work safely; follow department rules; and use personal protective equipment as needed. Report unsafe conditions and “near-misses” to supervision and avoid accidents and injuries. University of Wisconsin-Stevens Point EHS Manual Safety Orientation Effective: 05/29/16 Revised by the EHS Officer: 31of32 UWSP Safety Orientation Quiz TRUE / FALSE 1. Only serious injuries must be reported to Supervision and the Safety & Loss Control Office Control Office. 2. St. Michael’s Hospital Emergency Room is the closest emergency room for UWSP medical emergencies in Stevens Point. 3. Major Bloodborne pathogens are Hepatitis B and HIV. 4. Exposure to blood or potentially infectious body fluids may be reported to Supervision. 5. Confined spaces at UWSP are only in the steam pits. 6. Training is not required to enter confined spaces. 7. Emergency Procedures are linked to the UWSP Homepage through the Emergency Management Plan Link. 8. Releases of oil to the storm sewers are not reportable. 9. All oil spills must be cleaned up, but not all oil spills are reportable to the DNR. 10. Fire Extinguisher training is provided by Protective Services. 11. All hazardous chemicals and hazardous wastes must be properly identified. 12. Material Safety Data Sheets must be available to employees in their department. 13. MSDSs provide advice on protective equipment, compatibilities and spill response. 14. Primary containers of chemicals do not need labels. 15. All hazardous materials may be handled safely if proper PPE is used. 16. UWSP is a small quantity generator of Haz Waste. 17. HazMat Employees must be trained to know how to respond to emergencies. 18. Many accidents may be avoided by keeping the workplace clean and clutterfree. 19. Standing on the top of a step ladder is an acceptable practice. 20. For fires we evacuate and assemble up-wind to avoid smoke and for tornadoes we take shelter inside in the lowest levels away from windows and wide-span structures. T F T F T T F F T F T T F F T T F F T T T F F F T F T T T T T F F F F F T T F F I acknowledge that I attended this training, received the safety orientation, and understood the topics addressed. Contact your supervisor with any questions. Send a copy of the completed quiz to the EHS Officer at 101 Stien Bldg. Print Name Signature Department__________________________Date __________________ Effective 05/29/16 Send a copy of the completed quiz to the EHS Officer at 101 G. Stien Bldg.