RIVM report 320104004/2005 J.E. Delmaar, M.V.D.Z. Park, J.G.M. van Engelen Contact:

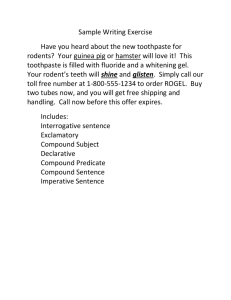

advertisement