Labor Tracking Know actual costs and beat out your competition. Configuration Options

advertisement

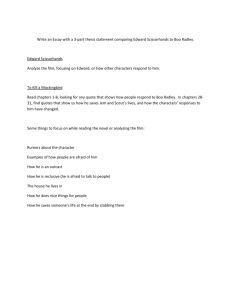

Labor Tracking Configuration Options • • • • • • • • • Track Operation Start and Stop Times Automatic Starts/Stops Batching – Process several jobs by one or more employees Prompt for Additional User-defined Data Scan Barcodes or Use Machine Integration Operator Classifications Machine Usage/Downtime/Reason Lot/Serial Tracking Indirect Labor Reporting Know actual costs and beat out your competition. Visibility to actual hours worked allows you to track direct and indirect time, and compare scheduled time with recorded time. Access to availability, performance and overall production quality data enables you to measure the metrics needed for Overall Equipment Effectiveness (OEE) statistics. Keep track of the activities of all your resources, both human and machine. You will know your output: completed, scrap, and rework quantities; so you will know your costs. www.radley.com BARCODE Data Collection Web Supplier Labeling Your ERP is automatically updated with labor hours, Shop Floor Control machine hours, completed and scrapped quantities and manufacturing completions. Complete transaction history Labor Tracking WorkForce Director Real-time data for queries, reports and analysis Task Prioritization Event Monitoring and exception reporting capabilities are standard. And, your data is secure with Supervisor review, maintenance and approval of all labor transactions. IntelliLabel PLC/Machine Integration Label License Plating Product Traceability Nested Container Management Find out how Radley’s WorkForce Productivity Solutions can work for you. Contact us today! Phone 1-616-554-9060 eMail info@radley.com