Automatic Guided Vehicles Reduce Labor Needs at Container Terminal

advertisement

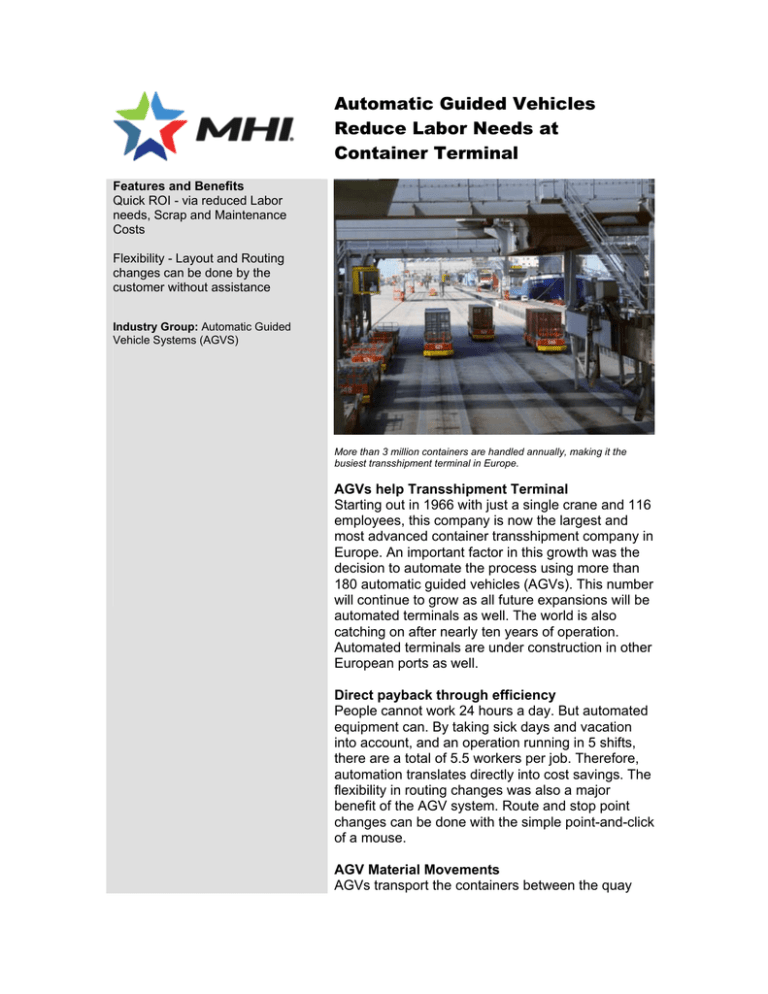

Automatic Guided Vehicles Reduce Labor Needs at Container Terminal Features and Benefits Quick ROI - via reduced Labor needs, Scrap and Maintenance Costs Flexibility - Layout and Routing changes can be done by the customer without assistance Industry Group: Automatic Guided Vehicle Systems (AGVS) More than 3 million containers are handled annually, making it the busiest transshipment terminal in Europe. transport pallets of Signature AGVs help Transshipment Terminal Starting out in 1966 with just a single crane and 116 employees, this company is now the largest and most advanced container transshipment company in Europe. An important factor in this growth was the decision to automate the process using more than 180 automatic guided vehicles (AGVs). This number will continue to grow as all future expansions will be automated terminals as well. The world is also catching on after nearly ten years of operation. Automated terminals are under construction in other European ports as well. Direct payback through efficiency People cannot work 24 hours a day. But automated equipment can. By taking sick days and vacation into account, and an operation running in 5 shifts, there are a total of 5.5 workers per job. Therefore, automation translates directly into cost savings. The flexibility in routing changes was also a major benefit of the AGV system. Route and stop point changes can be done with the simple point-and-click of a mouse. AGV Material Movements AGVs transport the containers between the quay cranes and the storage location. In the storage location, the containers are picked and put away by the rail-guided Automated Stacking Cranes. There is sufficient docking space for eight large container ships. There are typically three to four cranes dedicated to each large ship and eight AGVs per crane. Vehicle Paths The AGVs travel routes consisting of straight-line sections and 90o curves. The vehicle is entirely symmetrical: forward and backward speeds are the same, 11 km/h, and there are powered wheels on both axles. Frog AGV Systems 691 North Squirrel Road Suite 115 Auburn Hills, MI 48326 info@frogusa.com www.frogusa.com