LABORATORY SAFETY 243-4503 Environmental

advertisement

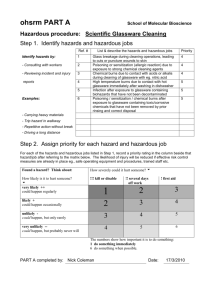

LABORATORY SAFETY Environmental Health and Risk Management EHRM 243-4503 http://www.umt.edu/research/eh/ Introduction Part 1. Laboratory Hazards & Safety Practices Hazard Communication Chemical & Physical Hazards Biological Hazards Hazardous waste Part 2. Emergency Procedures Hazard Communication Program 5 Elements of your RTK Program Training & Safety Awareness Chemical Inventory Material Safety Data Sheets Labeling Written Program Hazard Communication Chemical Inventory Chemical Inventory CHEMICAL INVENTORY Each Lab must have an inventory list of all chemicals present in the lab Sample Lab Chemical Inventory Hazard Communication Labeling Labeling Original Container Labels The label from the manufacturer must have the following: The chemical name Hazards of the chemical The manufacture’s name and address Target organ effects Original Container Label Example Secondary Container Labels All chemicals (including solutions and chemicals transferred from their original containers) should be labeled with their names*, concentrations and additional information such as: date received, date opened, date of expiration may also be recorded. *required Label should also include: All appropriate hazard warnings National Fire Protection Association (NFPA) Hazard Labels What are the health hazards? What are the fire hazards? What are the reactivity hazards? Are there any special hazards? 4 = Severe Hazard 3 = Serious Hazard 2 = Moderate Hazard 1 = Slight Hazard 0 = Minimal Hazard NFPA Hazard Label Examples Perchloric Acid Xylene Hazardous Material Identification System (HMIS) Labels HMIS Label Example Globally Harmonized System (GHS) Pictograms Environmental Acute Toxicity Systemic Health Effects Gases Other Health Effects Corrosives Globally Harmonized System (GHS) Pictograms Explosives Oxidizing Substances Flammable GHS Transport Labels Hazard Communication MSDS Material Safety Data Sheets MSDS Components 1. Identification of the substance or mixture and of the supplier 2. Hazards identification 3. Composition information on ingredients 4. First aid measures 5. Firefighting measures 6. Accidental release measures 7. Handling and storage 8. Exposure controls /personal protection 9. Physical and chemical 10. 11. 12. 13. 14. 15. 16. properties Stability and reactivity Toxicological information Ecological information Disposal considerations Transport information Regulatory information Other information Product Information You must know where to access the MSDS for chemicals in your lab. There may be hard copies or your lab may use online access or both. Be sure you know what your policy requires and how to follow it. Hazard Communication Written Policies Written Policies Sample Laboratory Safety Plan (Chemical Hygiene Plan) Your lab should already have a Chemical Hygiene Plan (CHP) in place and you should read it, ask any questions you might have about safe use of chemicals and sign the acknowledgement page in the plan for your lab. For new labs, a sample plan can be found at: http://www.umt.edu/research/eh/C HEMICAL%20HYGIENE%20PLA N.doc Develop a CHP appropriate for your laboratory and make sure that all workers are familiar with the plan Recommendations for Language to Include in Laboratory Safety Plan No eating, drinking or smoking in laboratory where chemicals are present Recommendations for Language to Include in Laboratory Safety Plan No applying cosmetics or handling contacts lenses in work areas where there is a possibility of exposure Recommendations for Language to Include in Laboratory Safety Plan Wear approved eye protection when handling chemicals and/or glassware Footwear that completely covers the feet is required, because of the danger of broken glass and the possibility of chemical spills. Secure the lab when unoccupied Two or more people in lab at all times Hazard Communication Program Training Training & Safety Awareness Laboratory Health Hazards "Health hazard" means a chemical for which there is statistically significant evidence that acute or chronic health effects may occur in exposed employees. Examples include: Carcinogens Toxic agents Irritants Corrosives Sensitizers Routes of Entry Eyes Skin Inhalation Ingestion Injection Routes of Entry Inhalation: The major route of entry when working with solvents. Great rapidity of absorption Routes of Entry Absorption: May produce systemic poisoning. Condition of skin determines rate of entry. Examples: organic lead, solvents, (xylene, methylene chloride) organo phosphate pesticides, cyanides Routes of Entry Ingestion: Usually accidental or due to poor hygiene practices Health Conditions Medical Conditions and Symptoms You should talk with your supervisor or doctor if you are working with hazardous chemicals and you: Are taking medication Are pregnant Have a medical condition such as a chronic allergy or asthma. Asthma is a common condition which can be exacerbated by breathing noxious chemicals. First Aid - Chemical Burns (Eyes) Forcibly open eyelids to ensure effective washing behind eyelid Wash from nose out to ear to avoid washing chemicals back into eye or into an unaffected eye • Flood eyes and eyelids with water/eye solution for minimum of 15 minutes First Aid - Chemical Burns (Eyes) • Remove contact lenses immediately to rinse eyes of harmful chemicals • Cover eyes with clean or sterile gauze • Call 4000 or proceed directly to the Emergency Room Make sure you know the location of the nearest eyewash station Eye Wash Maintenance Eyewashes are periodically checked by EHRM, but are not flushed A responsible party in each lab should be designated to flush the eyewash for one minute each week Chemical Burns - Skin • Remove any contaminated clothing • Chemicals may collect in shoes, remove shoes, if appropriate • Rinse area with large quantities of water for at least 15 minutes (sink, shower or hose) First Aid - Chemical Burns - Skin • DO NOT apply burn ointments/spray to affected areas • Cover with dry clean or sterile material • For large affected areas, call 4000 • If possible, bring the name of the chemical and/or its MSDS along with you to the evaluating medical facility. Report all injuries, no matter how small (investigations of near misses lead to fewer future injuries) First Degree Thermal Burns In general first degree burns have redness only, no blister or more extensive tissue damage. •Run cool water over area of burn or soak in cool water for at least 5 minutes. •Cover burn with a sterile bandage or clean cloth. •DO NOT APPLY ANY OINTMENTS, SPRAYS OR SALVES. Note: Burns can at first appear to be first degree, but blisters may develop over the next several hours. When in doubt, seek medical attention Second and Third Degree Thermal Burns Second and Third Degree burns are burns that have blisters or more extensive tissue damage. •If victim is on fire, put fire out. •Call 4000 •Do not remove any burnt clothing unless it comes off easily. •Cover burns with dry sterile or clean bandaging. •DO NOT APPLY ANY OINTMENTS, SPRAYS OR SALVES. First Aid - Wounds Wounds -- Significant bleeding • Call 4000 IMMEDIATELY • Calm and reassure victim • Lay victim down. (Reduces chance of fainting) • DO NOT remove any objects impaled in victim • Put direct pressure on wound with a sterile bandage or clean cloth • If direct pressure does not control bleeding, elevate wound above the heart if possible • If bleeding is severe elevate victims legs about 12 inches, and cover victim with a blanket • DO NOT APPLY TORNIQUET Personal Protective Equipment (PPE) Wear Eye Protection When Using: Glassware under reduced pressure Cryogenic materials Glassware under elevated pressure Explosives Caustics, Irritants or Corrosives Biohazards Radioactive Materials UV Light Toxic Chemicals Carcinogens Flammable Materials Lasers Eye Protection Wear goggles when using acids or whenever there is potential for a splash hazard Wear safety glasses at other times when chemicals are present and when handling glassware Face Protection Face protection should be worn when there is a possibility of a chemical splash to the face. A face shield is not a substitute for eye protection…..safety glasses or goggles must be worn in conjunction with a face shield. US&A (v 2/07) Gloves Gloves Cotton Leather Latex Viton Butyl Neoprene PVC Nitrile Other Gloves Be sure you know which type of glove is appropriate for the chemical you are using Example of wrong glove having been used Gloves Remove soiled gloves. If gloves become soiled or contaminated during experiment, stop, and remove carefully. Wash your hands and put on new pair of gloves. If you double-glove, remove soiled glove, replace outer glove with new one, and continue your work. Gloves “Fisher Scientific Safety Manual” also includes information on: Choosing size Proper removal Care and handling Gloves Check “Chemical Resistance Guide” in safety catalog for degradation rating and permeation breakthrough information for various chemicals (Xylenes: Nitrile) (Perchloric Acid: Nitrile, or PVC) Neoprene Chemical Storage Separate chemicals into compatible groups Designate separate storage for highly toxic chemicals •Do not store more chemicals than you will need over a reasonable time Storage (continued) Store corrosive, toxic, and highly reactive chemicals in a wellventilated area Store chemicals that can ignite at room temperature in a flammables cabinet Flammable Gas Store in cool, dry, well-ventilated surroundings, away from flammable substances including oil, grease and gasoline Storage (continued) Never store liquid hazardous chemicals above eye level Storage (continued) Chemicals stored overhead should be kept on shelves with raised edges. Storage (continued) Don’t store water reactive chemicals under sink Store heavy chemical containers on lower shelves and not on floor Storage (continued) Never store peroxide formers longer than 6 months. Examples: • Picric acid-make sure it stays wet • Ethyl ether (diethyl ether)-label when opened • Evaporation may lead to explosive compounds Examples of Poor Storage Never store a chemical with a missing or obscured label Leaks and Spills Chemical Spills -- Minor Spill considered minor only if person who spilled it is familiar with chemical, knows associated hazards and knows how to clean up spill safely Chemical Spills -- Minor Minor Spills Alert coworkers and proceed to clean up spill Contact Environmental Health and Risk Management for disposal of spill clean-up materials x4503 Chemical Spills -- Major Major Spills Anything beyond minor spill and requiring help from outside of the lab group Chemical Spills -- Major Alert coworkers Move to safe location Call 4000 to report situation Chemical Spills -- Major If you have specific information about the spill, remain available and identify yourself to firefighters, Public Safety or EHRM Spill Response Be prepared for emergencies Chemical Spills -- Absorbent Absorb free liquid with an appropriate absorbent: - Caustic - use polypropylene pads or diatomaceous earth. - Oxidizing acid - use diatomaceous earth. - Mineral acid - use baking soda or polypropylene pads. - Flammable liquids - use polypropylene pads. Neutralize residues and decontaminate the area. For larger spills EHRM has a mercury vacuum to assist in clean-up Avoid potential for mercury spills by using mercury free devices and procedures Mercury Spills Hazardous Waste Disposal Rules Minimize Containerize Label See UM rules: http://umt.edu/media/resea rch/Eh/Materials/Hazardo us/INFO%20%20UM%20Haz%20Mat% 20Plan/hazplanmarch2010 %20(2).doc Hazardous Waste Disposal Rules Minimize Containerize (Chemical waste in general, and hazardous waste in particular, must be stored in sturdy container, free of leaks.) Label Hazardous Waste Disposal Rules Minimize Containerize Label (All hazardous waste containers must be properly labeled.) Hazardous Waste Disposal Rules Do not use chemical symbols or abbreviations when labeling your containers Biohazardous Waste Disposal Autoclave or chemically disinfect Infectious Waste or Contact EHRM at x4503 for disposal Fire Safety – Lab Fires Small Lab Fire (extinguishable immediately): Cover fire with inverted beaker or wet paper towels. If this fails use fire extinguisher if properly trained and are familiar with hazardous decomposition products: P- Pull the pin A- Aim hose at base of fire S- Squeeze the handle SSweep hose back and forth Fire Safety Acetone Keep in mind that liquids with low flash points may ignite if they are near heat sources such as hot plates, steam lines or lab equipment which might produce a spark or heat. Physical Hazards: Autoclaves Refrigerators and Freezers Electrical Housekeeping Centrifuges Cylinders Fume Hoods Microwaves Radiation Ergonomics Broken Glass Sharps The major hazards are: 1. Burns resulting from physical contact. 2. Steam burns arising from contact with steam issuing from the apparatus. 3. Explosive breakages of glass vessels during opening and unloading. 4. Burns arising from careless handling of vessels containing boiling liquids. Autoclaves Rotors on highspeed centrifuge and ultracentrifuge units are subjects to powerful mechanical stress that can result in rotor failure. In addition, improper loading and balancing of rotors can cause the rotors to break loose while spinning. Centrifuges Everyone using this type of equipment needs to know the proper operating procedures for the specific unit being operated, including how to select, load, balance and clean the rotor. A Cornell University laboratory was seriously damaged when the rotor of an ultracentrifuge failed while in use. Flying metal fragments damaged walls, the ceiling and other equipment. The shock wave blew out the laboratory's windows and shook down shelves. The explosion completely destroyed the centrifuge. The safety shielding in the unit did not contain all the metal fragments. Centrifuge Do not locate where objects may strike or fall on cylinders Secure in upright position except hoisting or carrying Do not place where cylinder may become part of an electrical circuit Use cylinder truck, chain, and/or other steadying device to keep cylinders from being knocked over while in storage or use. Cylinder Safety Cylinder Safety Secure cylinders with a strap or chain. Regulators shall be removed and valve protection caps put in place when not in use. Cylinder Safety Always move cylinders with a cylinder cart and with the cap attached. Compressed Gas Lecture Bottle Labels: Flammable: flame on red label Non-flammable: gas canister on green background Poisonous: skull and crossbones Oxygen-containing: flaming letter “O” Chlorine: labels distinctly marked Electrical Safety QUESTION: At 100 volts what current level is sufficient to deliver a lethal shock? 25 mA 250 mA 2.5 amps 25 amps ANSWER: 25 mA can be life threatening. Make sure power is off before making connections. Beware of loose connections. If you feel a tingle when you touch the unit, stop using until it is repaired. Electrical Safety Eliminate frayed or worn wiring Never stretch wires across floor or other equipment. Staff should know location of circuit breakers Electrical Safety Match size of extension cord to appliance power cord to prevent cord overheating. Extension cords are not intended for "permanent" installations -appliances shall be connected to permanently wired receptacles. Electrical Safety Electrical "octopuses" can result in overloaded circuits and fire. Use only 15 amp fused power strips. Replace damaged wires Match appliance power requirements to circuit power. Use GFCIs when working with electrical equipment near water Only use extension cords with three prongs Tape down on floor or cover with rubber channels to eliminate tripping hazard Avoid use with high temperature, over sharp edges, or in traffic areas Inspect and test cords and outlets regularly Use with GFCIs, outdoors and in wet or damp areas, and in construction Electrical Safety Electrical Safety •Maintain 3’ clearance in front of circuit breaker panels. Blocked Unblocked Fume Hoods Place apparatus and equipment as far back as possible in hood for safety and optimal performance. Equipment should be placed a minimum of 6 inches inside the hood. Keep electrical connections outside of hood. Fume Hoods Ensure that equipment or materials do not block the baffle vents in the back of the hood. Fume Hoods When using a large apparatus inside the hood, place the equipment on blocks, when safe and practical, to allow air flow beneath it. US&A (v 2/07) Do not make quick motions into or out of the hood, use fans, or walk quickly by the hood opening. All will cause airflow disturbances which reduce the effectiveness of the hood. Fume Hoods Do not remove stops from sliding sash hoods. Use sliding sash for partial protection during hazardous work. When not in use, the sash should be within 1-2 inches of full closure. Fume Hoods For information on the campus radiation safety program or other radiation related topics please contact the Radiation Safety Officer at 2881. Radiation Safety Microwave Ovens Microwave ovens are used in the workplace for various applications including sample preparation procedures in research labs. •Injuries may also result from items being heated or from explosions from pressure built up in sealed containers or ignition of volatile materials. Refrigerators and Freezers Ordinary household refrigerators and freezers constitute a hazard when used for storage of flammable or unstable chemicals. These units produce sparks that can lead to explosions. Domestic refrigerators should not be used for flammable chemical storage. "Lab-safe" refrigerators and freezers (designed for storage of flammable liquids) must be used for flammable chemicals. All chemicals should be sealed and labeled with the name of the material, the date it was placed in storage, and the name of the person storing it there. Refrigerators and freezers should be cleaned on a regular schedule, and old chemicals should be properly discarded through the UM waste disposal program. DO NOT store food in any refrigerator used to store chemicals. Refrigerators and Freezers Ergonomics Ergonomics is the study of designing equipment and devices that fit the human body, its movements, and its cognitive abilities. Proper ergonomic design and work practices are necessary to prevent repetitive strain injuries Please contact EHRM at 4503 for assistance with ergonomic concerns. Ergonomics Biosafety Cabinets: May compromise the human neutral position, including chair design, foot support and overall design Newer BSCs incorporate footrests and height- adjustable work surfaces Pipettes: Have evolved over the years from mouth pipetting to rubber suction balls to electronic pipette dispensers. Whatever the mechanism, repetitious movements occur. Ergonomics Ergonomics Microscopes by nature are not designed for workers. Predominant ergonomic hazards include: Neck flexion Back flexion Rounding of back and shoulders Ergonomics Ergonomic improvements begin with chair, arm and leg interface. Utilize adjustable chairs, analyze work height , adequate arm/hand rests and micro-breaks to reduce “repetitive stress injuries” (RSIs) Spending long blocks of time at computer can lead to “repetitive stress injuries” (RSIs) There are many devices available designed to minimize this potential. Ergonomics Reduce your potential risk of RSIs by taking occasional “micro breaks.” Schedule a short break after approximately 15 minutes of continuous computer keying Housekeeping Keep your work area neat at all times. Do not force a rubber stopper onto glass tubing or thermometers. Lubricate the tubing and the stopper with glycerol or water. Use paper or cloth toweling to protect your hands. Grasp the glass close to the stopper. Housekeeping -Laboratory Glass Laboratory Glass Clean laboratory glassware at the conclusion of your experiment. Make sure glassware racks do not interfere with eye wash station access. Housekeeping -- Broken Glass Broken, contaminated glassware can cause chemical exposure Do not use broken, chipped, starred or cracked glassware. Broken glass must be placed in a separate container. Take special precautions when handling contaminated glassware Housekeeping -- Broken Glass Do not pick up broken glass with bare hands Dispose in a sealed container. Separate sharps: scalpel blades razor blades needles Sharps Use needles, capillary tubes, scalpels and other sharp instruments with extreme caution to prevent punctures and cuts Sharps -- Recapping Recapping is not recommended and is not necessary for disposal If recapping is imperative, the correct procedure is: Keep one hand behind the back, use other hand to scoop cover onto needle Sharps Disposal Put sharps in punctureresistant, leak-proof, sharps container. Label the container with the word, "SHARPS”. If not biohazardous, deface any "BIOHAZARD" markings or symbols. Seal container tightly. •Contact EHRM x4503 for pickup. Hazardous Material Shipping If you are going to ship hazardous materials to another location, you must have Department of Transportation training. The requirements can be met by completing the materials found at: http://www.umt.edu/media/research/eh/ Materials/Hazardous/INFO%20%20for%20UM%20Laboratories/hazmattr ansport.pdf More Information Most accidents including those in the lab working with chemicals are caused by a lack of understanding of the properties of the materials you are working with or a lack of attention to detail or a combination of both. If you have any questions about materials you are working with, be sure and ask the responsible person in your lab. Please see the OSHA new guidance document on Laboratory Safety http://www.osha.gov/Publications/laboratory/OSHA34 04laboratory-safety-guidance.pdf Emergency Procedures Question: What should you do in an emergency? •For Fire? •For Chemical Spills ? •Other emergencies? Answer: Call 4000 from any campus phone Emergency Procedures Follow the University of Montana Emergency Procedure Guide posted in each Lab. US&A (v 2/07) Fire Safety Procedures •Alert persons in area of fire •Close doors to confine fire •Activate fire alarm •Evacuate through nearest exit •Do not use elevators •Move away from the building. Quiz You need to print and complete the following quiz. Once done, give it to the person in charge of your lab. They will correct it and once corrected, file it in the notebook containing the Chemical Hygiene-Lab Safety plan for your lab. Right click this link to open the quiz in Microsoft word: http://www.umt.edu/media/research/eh/Materials/Haza rdous/INFO%20%20for%20UM%20Laboratories/safetyquiz.doc Final Steps The final steps in this process require you to read through the Chemical Hygiene-Lab Safety Plan for your lab, ask your lab supervisor about any questions you might have regarding the plan and sign the acknowledgement page in the plan notebook. In the course of the discussion with your lab supervisor about the plan, you should be made aware any special or unusual hazards in your work area. You will not have to re-visit this training until such time as a new hazard is introduced in your work area. A new hazard may be a different chemical class or type of instrument.