Evaluation Board for 2-Channel 500 MSPS DDS with 10-Bit DACs AD9958/PCB

advertisement

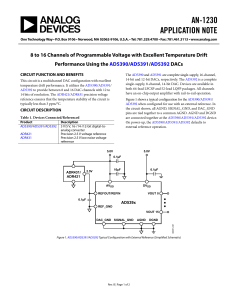

Evaluation Board for 2-Channel 500 MSPS DDS with 10-Bit DACs AD9958/PCB EVALUATION BOARD BLOCK DIAGRAM AD9958 EVALUATION BOARD XTAL BUFFER/XTAL OSCILLATOR J9 BALUN REFCLK MULTIPLIER 4X TO 20X MUX REF_CLK SYS CLK J3 DAC 0 OUT J7 J13 ÷4 SYNC_CLK SYS CLK SYS CLK DAC 0 IOUT DDS 0 DAC 0 FILTER OUT LPF DAC 0 IOUT TIMING AND CONTROL LOGIC J4 DAC 1 OUT J8 J11 SYNC_IN SYS CLK DAC 1 IOUT DDS 1 DAC 1 FILTER OUT LPF DAC 1 IOUT J12 05783-001 SYNC_OUT Figure 1. FEATURES GENERAL DESCRIPTION Full-featured evaluation board for the AD9958 PC evaluation software for control and measurement of the AD9958 USB interface Graphic user interface (GUI) software with frequency sweep capability for board control and data analysis Factory tested and ready to use This document serves as a guide to the setup and use of the AD9958 evaluation board. The AD9958 is a multichannel frequency synthesizer that incorporates two synchronous direct digital synthesis (DDS) cores with many user-programmable functions. APPLICATIONS AD9958 performance evaluation GUI control panel for learning AD9958 programming The evaluation board software provides a graphical user interface for easy communication with the device along with many user-friendly features such as the “mouse-over effect.” Many elements of the software can be clarified by placing your mouse over the element. Figure 19 shows how this feature works when users place their mouse over the Ref Clock box. This document is intended for use in conjunction with the AD9958 data sheet, which is available from Analog Devices at www.analog.com. Rev. 0 Information furnished by Analog Devices is believed to be accurate and reliable. However, no responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other rights of third parties that may result from its use. Specifications subject to change without notice. No license is granted by implication or otherwise under any patent or patent rights of Analog Devices.Trademarks and registered trademarks are the property of their respective owners. One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A. Tel: 781.329.4700 www.analog.com Fax: 781.461.3113 ©2006 Analog Devices, Inc. All rights reserved. AD9958/PCB TABLE OF CONTENTS Evaluation Board Block Diagram................................................... 1 Evaluation Board Software...............................................................5 Features .............................................................................................. 1 Installing the Software ..................................................................5 Applications....................................................................................... 1 Configuring the Evaluation Board..............................................5 General Description ......................................................................... 1 Loading the Software ....................................................................7 Revision History ............................................................................... 2 Feature Control Windows............................................................9 Evaluation Board Hardware ............................................................ 3 Setup Files.................................................................................... 17 Package Contents.......................................................................... 3 Schematics ....................................................................................... 24 Requirements ................................................................................ 3 Ordering Information.................................................................... 27 Setting up the Evaluation Board................................................. 3 Ordering Guide .......................................................................... 27 Evaluation Board Layout ............................................................. 4 ESD Caution................................................................................ 27 REVISION HISTORY 1/06—Revision 0: Initial Version Rev. 0 | Page 2 of 28 AD9958/PCB EVALUATION BOARD HARDWARE Table 2. Connections and Biasing Voltage PACKAGE CONTENTS Connector TB1 TB1 TB1 TB1 J10 J16 J18 J20 The AD9958/PCB kit contains the following items: • AD9958 evaluation board • AD9958/PCB installation software REQUIREMENTS In order to successfully use the evaluation board and run the software, the requirements listed in Table 1 must be met. Table 1. AD9958/PCB Requirements Item Operating System Processor Memory Ports Clocking Power Supplies Measurement Cables Requirement Windows® 98/Windows® ME/ Windows® 2000/Windows® XP Pentium® I or better 128 MB or better One USB port Signal generator capable of generating sinusoidal waves of at least 3 dBm power, up to at least 10 MHz Capability to generate at least two independent dc voltages (1.8 V/3.3 V) Appropriate measurement device, such as a spectrum analyzer or a high bandwidth oscilloscope USB 1.1/2.0 cable, and SMA-to-X cables (X = SMA or BNC, depending on the connector of the device interfacing with the board) SETTING UP THE EVALUATION BOARD Pin No. 1 2 3 4 Label VCC_USB DVDD_I/O GND DVDD CLK_VDD AVDD BG_VDD AVDD Voltage (V) 3.3 3.3 0 1.8 1.8 1.8 1.8 1.8 Note that the AD9958/PCB is preconfigured so that the CLK_VDD, BG_VDD, and all other AVDD connections are tied together. Therefore, only one connection (J10, J16, J18, or J20) needs power for proper functionality of the two channels. These AVDD connections can be separated for better channel isolation. This is accomplished by removing the 0 Ω resistors (R21, R32 to R51, R54 to R64), which tie the planes together, found on the back of the evaluation board. When doing this, be sure that CLK_VDD, BG_VDD, and the AVDD connection for all desired channel(s) are powered. Clocking the Part The AD9958 architecture provides the user with two options when providing an input signal to the part. Figure 1 shows that the user can clock the frequency synthesizer/DDS directly by connecting an external clocking signal to the REF_CLK connector, J9, or by providing an external crystal. Place Jumper W11 on REF_CLK to use the external clocking option. To use an external crystal as the clocking source, place Jumper W11 on CRYSTAL. Please refer to the AD9958 data sheet for details on the maximum input speeds and input sensitivities of these two inputs. Powering the Part The AD9958 evaluation board has five power supply connectors: TB1, J10, J16, J18, and J20. TB1 powers the DDS, the PC interface logic, and the USB circuitry. J10 powers the input clock circuitry. J18 provides the reference voltage needed for band gap functionality. J16 and J20 power the analog circuitry of individual DACs. It is important to keep in mind that the AD9958 evaluation board has been preconfigured so that these two AVDD connections are tied together. Supplying power to any one of the AVDD connections (J16 or J20) allows for the proper functionality of the analog circuitry of both DACs. Table 2 shows the necessary connections and the appropriate biasing voltage. Communicating with the Part Two interface standards are available on the evaluation board: • USB 1.1/2.0 interface • Header row (U2, U13), which places the part under the control of an external controller (such as a µP, FPGA, or DSP) Analog Devices provides a GUI for the PC; it does not provide control software for external controllers. Use the jumper settings listed in Table 3 to enable different modes of communication. Table 3. Jumper Settings for Communication Modes Mode PC control, USB port External control Rev. 0 | Page 3 of 28 Settings Set W7 to PC. Place a jumper on W1, W2, W3, W9, and W10. Set W7 to manual. Place a jumper on W9, and remove W1, W2, W3, and W10 (or leave it stored as a shunt). AD9958/PCB EVALUATION BOARD LAYOUT MULTIDEVICE SYNCHRONOUS CONTROL MANUAL I/O CONTROL HEADERS DAC CHANNEL NOT USED DAC CHANNEL NOT USED EVALUATION BOARD CONTROL CLOCK INPUT SUPPLY USB PORT CLOCK MODE SELECT REF CLK INPUT SDIO RU/RD CONTROL POWER SUPPLY DAC CHANNEL 0 DAC CHANNEL 1 05783-002 BAND GAP SUPPLY Figure 2. Manual I/O Control Headers Power Supply Provides the interface for communication with the AD9958 when the part is under the control of an external controller (manual control). See Eval Board Control for correct jumper settings. Powers the AD9958’s USB circuitry, I/O circuitry, and the digital portion (DVDD) of the DACs. Note AVDD is not powered via this connector (TB1). Multidevice Synchronous Control These connections represent the DAC filtered/unfiltered output and AVDD power supply. DAC Channels These connections set up the AD9958 for multidevice synchronous operation. RU/RD Control, SDIO Clock Input Supply Powers the AD9958’s clock input circuitry. Jumper W6, Jumper W5, and Jumper W4 must be set to control the Ramp Up/Ramp Down feature using the SDIO pins. Clock Mode Select USB Port Controls whether the part is driven by a 20 MHz to 30 MHz crystal provided by the user or by an external signal generator such as REF_CLK. When the part is under PC control (default mode), the evaluation board communicates with the AD9958 via this port. REF_CLK Input These jumpers set up the AD9958 for manual or PC control (control through the USB port). Figure 2 shows the correct jumper placements for PC control. For manual control, remove Jumper W0 to Jumper W3; set Jumper W7 on the manual control pin (move jumper one position to the left). Input for the external REF_CLK signal. Band Gap Supply Provides the voltage needed for band gap functionality. Eval Board Control Rev. 0 | Page 4 of 28 AD9958/PCB EVALUATION BOARD SOFTWARE 4. INSTALLING THE SOFTWARE Then, this window (Figure 4) appears and disappears. 1. Log on to your PC system with administrative privileges; this is an essential requirement in successfully installing the AD9958 evaluation software. 2. Uninstall any previous versions of the AD9958 evaluation software from your PC system. 3. Insert the AD9958 evaluation software CD into your CD-ROM drive. It is important not to connect the AD9958 evaluation board to the computer until the AD9958 evaluation software has been successfully installed. Refer to the Readme.txt file located in the Software folder before proceeding with the installation of the AD9958 evaluation software. 4. Run the setup.exe file located in the Software folder and follow the AD9958 evaluation software’s on-screen installation instructions. 05783-004 Follow these steps to install the AD9958 evaluation software. Figure 4. 5. If you are using Windows 2000, click Finish if you see this window (Figure 5). CONFIGURING THE EVALUATION BOARD 05783-005 Once the software has been successfully installed onto your PC, the next step is to interface the AD9958 evaluation software to the AD9958 evaluation board via the USB Port (see Figure 2). For the evaluation board and software to communicate properly, drivers must be loaded onto your PC system. The following instructions explain how to install these drivers on your PC system. Figure 5. 6. Next, the window in Figure 6 appears. 1. Power up the AD9958 evaluation board (see Table 2). 2. Connect the evaluation board to the computer using a USB cable via the USB port; the VBUS LED (CR1 on AD9958 evaluation board) illuminates. 3. When the USB cable is connected, this window appears and then disappears (Figure 3). 05783-006 Windows 98/Windows ME/Windows 2000 Users Figure 6. 05783-003 After the window has disappeared, the USB Status LED (CR2 on the AD9958 evaluation board) flashes, which indicates that the evaluation board is connected properly. Figure 3. Rev. 0 | Page 5 of 28 AD9958/PCB 5. Windows XP Users Power up the AD9958 evaluation board (see Table 2). 2. Connect the evaluation board to the computer using a USB cable via the USB port. Then, the VBUS LED (CR1 on AD9958 evaluation board) illuminates. 3. When the USB cable is connected, the following window appears (Figure 7). Click Next to continue. 05783-009 1. Click Finish after this window (Figure 9) appears. Figure 9. Click Next after you see the following window (Figure 10). 05783-007 6. Figure 7. 05783-010 Click Continue Anyway when you see the window in Figure 8. Figure 10. 7. Click Continue Anyway when this window (Figure 11) appears. 05783-008 Figure 8. 05783-011 4. Figure 11. Rev. 0 | Page 6 of 28 AD9958/PCB 8. After the window in Figure 12 appears, click Finish to exit. LOADING THE SOFTWARE Follow these three steps to load the AD9958 evaluation software. Before starting the software, make sure that the AD9958 evaluation board is powered up, connected to the computer, and that the USB Status LED is flashing. 2. Click the Start button, located at the bottom left-hand corner of your desktop. 3. Select All Programs > AD9958_59 Eval Software folder > AD9958_59 Eval Software to load the software (see Figure 13). 05783-012 1. Figure 12. 05783-013 Once this screen has disappeared, you should notice that the USB Status LED (CR2 on AD9958 evaluation board) is flashing, which indicates that the evaluation board is connected properly. Figure 13. After completing these steps, the AD9958 evaluation software loads onto your PC system. You are then presented with one of several status messages. These messages are discussed in further detail in the next section, Status Messages upon Loading Software. Rev. 0 | Page 7 of 28 AD9958/PCB Status Messages upon Loading Software Once the AD9958 evaluation software has been loaded, a green splash screen appears as shown in Figure 14. The status box within the splash screen gives the status of the AD9958 evaluation software. A cursor is provided for easy navigation throughout this box. Green writing in the status box indicates that the software has loaded successfully. A splash screen with red writing in the status box indicates that the software did not load successfully and that an error occurred (see Figure 15). Scrolling up through the status box with the cursor indicates why the software did not load correctly. Most status message errors can be resolved by checking jumper settings, making sure that the evaluation board is powered up correctly, and inspecting the USB port and cable connections. When all power connections, USB port/cable connections, and jumper settings are correct, an error can still appear if the clock input is not properly configured. If this occurs, a pop-up window appears in the center of the splash screen explaining that the software does not recognize the REF_CLK input. Follow the directions given (see Figure 16). 05783-014 SPLASH SCREEN 05783-015 05783-016 Figure 14. Successful Load Figure 16. REF_CLK Not Recognized Figure 15. Error Message Rev. 0 | Page 8 of 28 AD9958/PCB FEATURE CONTROL WINDOWS Chip Level Control 2 5 6 3 1 05783-017 4 Figure 17. Chip Level Control Window The Chip Level Control window provides control of the features that affect all channels of the AD9958; this window is not channel-specific. The following section describes the options in the Chip Level Control window as they are numerically indexed in Figure 17. 2. Clock Clock allows the user to configure the reference clock path in the AD9958. LOAD and READ The LOAD and READ buttons are used to send data and retrieve register settings. All LOAD and READ buttons found in the evaluation software have the same functionality. When new data is detected, LOAD flashes orange, indicating that you need to click LOAD to send the updates to the serial I/O buffer where they are stored until an I/O update is issued. The I/O update sends the contents of the serial I/O buffer to active registers. 05783-018 I/O updates can be sent manually (Manual I/O Update) or automatically (Auto I/O Update). By default, the AD9958 evaluation software is set to Auto I/O Update, so that when LOAD is clicked, an I/O update signal is automatically sent to the device. If synchronization across channels is desired, use the Manual I/O Update button. To do this, deselect the Auto I/O Update box and click the Manual I/O Update button when you wish to send an I/O update (see Figure 18). Ref Clock inputs the operating frequency of the external reference clock or crystal. The maximum reference clock frequency of the AD9958 is 500 MHz, which is the default setting of this box. A red outline indicates that the value entered is out of range (see Figure 19). 05783-019 1. Click READ to perform a readback of the current state of the settings and update the GUI with those settings. Figure 19. Multiplier selects the PLL multiplication factor (4× to 20×) by which to scale the input frequency. The default setting of this box is Disabled, indicating that the Ref Clock Multiplier circuitry is bypassed and the Ref Clock/Crystal input is piped directly to the DDS core. Figure 18. Rev. 0 | Page 9 of 28 AD9958/PCB CP Current selects the charge pump current output of the PLL in the Ref Clock Multiplier circuitry. Selecting a higher current output results in the loop locking faster, but there is a trade-off. Increasing this current output also increases phase noise. The default setting of this box is 75 μA. System Clock displays the operating frequency of the DDS core (system). The value shown here is derived from the values entered in the Ref Clock and Multiplier boxes. 05783-020 VCO Gain is automatically set when the Ref Clock Multiplier is being used to generate a system clock that is greater than 255 MHz. This is done to ensure stability of the Ref Clock Multiplier circuitry. A pop-up window appears alerting you to this update (see Figure 20). Figure 20. Please refer to the Reference Clock Modes section of the AD9958 data sheet for more information regarding clock modes and operation. 3. The AD9958 can be configured to perform many operations in various combinations. Please refer to the Channel Constraint Guidelines and the Modulation Mode sections of the AD9958 data sheet for more details regarding the use of the RU/RD function in combination with the different modes of operation (single tone, modulation, linear sweep) of the AD9958. For more information regarding the theory of the RU/RD operation, note the Output Amplitude Control Mode section of the AD9958 data sheet. Level selects the desired level of modulation of the AD9958. The AD9958 can perform 2-level, 4-level, 8-level, or 16-level modulation of frequency, phase, or amplitude (FSK, PSK, ASK). This modulation is controlled via the data pins; note the Channel Constraint Guidelines and the Modulation Mode sections of the AD9958 data sheet for more details. 5. All Channel Accumulator Control The All Channel Accumulator Control provides control over the phase and sweep accumulators for both channels. Select the Auto Clear Phase Accumulator or Auto Clear Sweep Accumulator boxes to clear and release the corresponding accumulator. The autoclear function sets the accumulator to 0 and then begins accumulating. Modulation Configuration Modulation Configuration configures the modulation operation of the AD9958. Profile Pin Config provides access to the PPC Bits (FR1<14:12>). These bits are used to control the modulation scheme of the AD9958. PPC Bit 0 is the LSB (FR1<12>), and PPC Bit 2 is the MSB (FR1<14>).When a PPC bit is selected, it is set to Logic 1 from its default setting of 0. These bits are discussed in more detail in the Modulation Mode section. Multi Device Sync It is possible to synchronize multiple evaluation boards. Refer to the Synchronizing Multiple AD9958 Devices section in the AD9958 data sheet and the evaluation board schematic (located in the schematic folder of the AD9958_59 evaluation software CD) for more details on synchronizing multiple AD9958s. 6. Select the Clear Phase Accumulator or Clear Sweep Accumulator boxes to clear and hold the corresponding accumulator. The clear function clears and then holds the contents of the corresponding accumulator to 0 until the box is deselected. 4. Select Use Profile Pins 2 & 3 if you would like to control the RU/RD feature with Profile Pin 2 and Profile Pin 3, or Use Profile Pin 3 to control this feature using only Profile Pin 3. If you wish to use the SDIO data pins to control this feature, simply select Use SDIO Pins 1, 2 & 3. Note that to use the SDIO pins to control the RU/RD feature, the SDIO and RU/RD control jumpers must be placed (see Figure 2). The default setting of this box is RU/RD Disabled. In this mode, you are not able to scale the output amplitude. All Channel Power Down All Channel Power Down allows you to power down both channels collectively using software configurations or the external power-down options found in External PD Control. Select the Clock Input, DAC Ref, or Disable SyncCLK Out boxes to power down those circuit blocks, respectively, for each individual channel. Once the selection has been made, click the LOAD button to execute the power down. When using the External PD Control, select from the Power Down Pin Mode: Quick Recovery (default setting) or Full Power Down. In quick recovery mode, only the digital logic is powered down whereas all functions are powered down in full power-down mode. To execute the power down when using external PD control, you must click the Power Down Pin. When pressed, the power-down pin is at Logic 1, indicating the power-down mode. When this pin is not pressed, it is at Logic 0, indicating the power-up mode. RU/RD assigns which pins control the scaling (Ramp Up/Ramp Down) of the output amplitude of the AD9958. This feature can be controlled via the profile or SDIO data pins. Rev. 0 | Page 10 of 28 AD9958/PCB Channel Control 1 5 6 2 3 7 4 05783-021 8 Figure 21. Channel Control Window 1. Channel 0 and Channel 1 Use the Channel 0 and Channel 1 tabs to select which specific channel options to configure. The AD9958 has two independent channels: Channel <0:1>. The default channel tab setting is Channel 0. 2. Pwr Down Use Pwr Down to power down the digital logic (select Digital) or the DAC circuitry (select DAC). Upon default, both of these boxes are not selected, indicating that the digital logic and the DAC circuitry of that channel are enabled (powered up). 3. Modulation Output Type The Modulation Output Type list controls what type of modulation is performed on the channel’s output. Select Phase, Frequency, Amplitude, or None (Single Tone) depending on which type of modulation you want. The level of modulation for the channel is set using the Chip Level Control window under Modulation Configuration in the Level box. 4. 05783-022 The Channel Control window provides control of the features that affect the AD9958 at a channel-specific level. The following section describes the options of the Channel Control window as they are numerically indexed in Figure 21. Linear Sweep Options Use the Linear Sweep Options to control the linear sweep features. Select Enable Linear Sweep to turn on the linear sweep function and the additional associated options (see Figure 22). Figure 22. Select Linear Sweep No Dwell to enable this feature. See the Linear Sweep No Dwell Mode section of the AD9958 data sheet for more information regarding the no dwell feature. When you select Load SRR @ I/O Update, the contents of the sweep ramp rate register are loaded into the sweep ramp rate timer every time an I/O_UPDATE is sent to the device. The Clear Sweep Accumulator and Auto Clear Sweep Accumulator have the same basic functionality as described in the All Channel Accumulator Control section. The difference is that here the function is channel-specific. See the Linear Sweep (Shaped) Modulation Mode section of the AD9958 data sheet for a detailed explanation of this mode. 5. Pipe-Line Latency Control When you select the Match Pipe Delays box under Pipe-Line Latency Control, the pipeline delay for updates to frequency, amplitude, and phase are equal, but only for the channels operating in single tone mode. The default setting of this box is not selected, meaning the pipeline delay for updates to frequency, amplitude, and phase is not equal. Rev. 0 | Page 11 of 28 AD9958/PCB See the DATA LATENCY (PIPELINE DELAY) section in the Specifications table of the AD9958 data sheet for the exact timing delays with and without this feature enabled. Also, refer to the Single Tone Mode-Matched Pipeline Delay section of the AD9958 data sheet. In the Output Waveform box, select either a Cosine or a Sine function for the angle-to-amplitude conversion. The default setting is Cosine. 6. 8. DAC Full Scale Current Control Use DAC Full Scale Current Control to scale the output current of the DAC. Select either Full Scale (default setting), ½th Full Scale, ¼th Full Scale, or ⅛th Full Scale for the DAC output current. See the Scalable DAC Reference Current Control Mode section of the AD9958 data sheet. 7. Output Waveform Phase Accumulator Control The Clear Phase Accumulator and Auto Clear Phase Accumulator have the same basic functionality as described in the All Channel Accumulator Control section. The difference here is that the function is channel-specific. Rev. 0 | Page 12 of 28 AD9958/PCB Channel Output Config 1 4 2 05783-023 3 Figure 23. Channel Output Config Window The Channel Output Config window configures various output characteristics of the channel(s). Use the Channel 0 and Channel 1 tabs to select which specific channel options to configure. The following section describes the options that are numerically indexed in Figure 23. 1. The Frequency 00 box also sets the starting point of the linear frequency sweep and the first level in frequency modulation (FSK). Phase Offset consists of two fields. In the first field, set the integer factor (1 to 999) to increment or decrement the phase offset. The default setting of this field is 1, indicating that the phase offset is incremented/decremented by .022 degrees when pressing the up or down arrow keys. The value of .022 degrees is derived from this equation: Single Tone Setup Use Single Tone Setup to configure the channel output for the single tone mode of operation (default). Enter the desired output frequency directly in the Frequency 00 box or double-click the Frequency 00 box to launch the Edit Output Frequency pop-up box to set the output frequency in the Frequency box. The output frequency can alternatively be set in decimal, hex, or binary format by editing the respective boxes in Tuning Word Values (see Figure 24). 1 Integer Factor × ⎛⎜ (14 bits of phase resolution)−1 ⎞⎟ × 360 ° ⎝2 ⎠ Therefore, entering a factor of 3 in the first field allows you to increment/decrement the phase offset by .066 degrees. In the second box, input the desired phase offset (from 0 degrees to 360 degrees) of the output signal. 05783-024 The Phase Offset box also represents the starting point of the linear phase sweep and the first level in phase modulation (PSK). Figure 24. In order to use the output amplitude scalar, the Enable ASF check box must be selected. In the first field, set the integer factor (1 to 999) to increment or decrement the amplitude scale factor. The default setting of this field is 1, meaning the output amplitude is scaled up/down by .00098 when pressing the up or down arrow keys. The value of .00098 is derived from this equation: Note that the Phase Offset, Enable ASF, Amplitude Ramp Rate, Rising Step Size, Rising Step Interval, Falling Step Size, and Falling Step Interval boxes all offer the edit option shown in Figure 24 by double-clicking their respective boxes. Rev. 0 | Page 13 of 28 1 Integer Factor × ⎛⎜ (10 bits of output amplitude scalar resolution)−1 ⎞⎟ ⎝2 ⎠ AD9958/PCB In the second field, set the desired output amplitude scale factor (between 0 and 1) of the output signal, where 1 is equivalent to full scale. The Enable ASF check box also represents the starting point of the linear amplitude sweep and the first level in amplitude modulation (ASK). Note that when performing linear amplitude sweeps, the Enable ASF check box must be left clear. Profile Registers The AD9958 features up to 16 programmable registers per channel as shown in Figure 23. Due to certain channel constraints, however, there are limitations on how the Profile Registers can be used in some configurations as described in the Channel Constraint Guidelines section of the AD9958 data sheet. Use the Profile Registers to enter the information needed for modulation (FSK, PSK, or ASK) and linear sweep modes of operation. Upon default, the Profile Registers are configured for frequency inputs, but these registers can be changed to intake phase or amplitude information by selecting the desired modulation type in the Modulation Output Type list in the Channel Control window. Figure 27 shows how the Profile Registers appear when phase modulation (PSK) is selected. 05783-025 When using the RU/RD feature, the Enable Auto ASF check box must be selected. Once the Enable Auto ASF check box has been selected, the Amplitude Ramp Rate, Amplitude Step Adjust, and the Load ARR @ I/O Update options are available (see Figure 25). 2. Figure 25. ⎛ 1 ⎜ ⎜ SYNC CLK ⎝ 05783-027 Use the Amplitude Ramp Rate field to set the amplitude ramp rate (ARR) time. This time (entered in μs) can range from a minimum value of ⎞ ⎟ ×1 ⎟ ⎠ Figure 27. to a maximum value of ⎛⎛ 1 ⎜⎜ ⎜ ⎜ SYNC CLK ⎝⎝ ⎞ (8 bits of output ramp rate resolution )−1 ⎞ ⎟ ⎟×2 ⎟ ⎟ ⎠ ⎠ 05783-026 This implies that if the system clock is 500 MHz, the ARR value can range from 8 ns (minimum) to 2.040 μs (maximum). If the value entered exceeds the maximum time, a pop-up window (Figure 26) alerts the user that the value entered will be changed to the appropriate maximum value. When the channel is in the modulation or linear sweep mode of operation, input the starting frequency in the Frequency 00 field, starting phase in the Phase Offset field, and the starting amplitude in the Enable ASF field. In modulation mode, use the Profile Registers to input frequency, phase, or amplitude information for the level of modulation selected. For instance, if 4-level frequency modulation is selected, input the starting frequency in the Frequency 00 field, second frequency in the Frequency 01 field, third frequency in the Frequency 02 field, and fourth frequency in the Frequency 03 field. An example of using the Profile Registers for 2-level frequency modulation is shown in Figure 28. In this configuration, the frequency starts at 10 MHz and ramps up to 50 MHz. Figure 26. In the Amplitude Step Adjust drop-down box, select the amplitude scale factor step size. The default setting of this dropdown box is 1, indicating that step size is 1 LSB. A selection of 8 means the step size is 8 LSB. Select Load ARR @ I/O Update to load the contents of the amplitude ramp rate register into the amplitude ramp rate timer every time an I/O_UPDATE is sent to the device. Rev. 0 | Page 14 of 28 AD9958/PCB If performing 2-level frequency modulation (no RU/RD) and had the same configurations as shown in Figure 28, P2 would be used to control the modulation on CH0 (see datasheet for more information). Therefore, the output of CH0 stays at 10 MHz until the P2 button is clicked. Once the P2 button is selected, the frequency changes to 50 MHz. To return to 10 MHz, simply release (click off) P2. For more information regarding the use of the profile and SDIO data pins to control various modulation, linear sweep, and RU/RD schemes, refer to the Modes of Operation section of the AD9958 data sheet. 4. Linear Sweep Setup Use Linear Sweep Setup to setup the slope of the linear sweep. In the Rising Step Size field, enter the desired value for the rising step size. Input the amount of time you wish to be spent at each step in the Rising Step Interval field. 05783-028 Input the desired falling step size in the Falling Step Size field, and the time that should be spent at each step in the Falling Step Interval field. The Rising/Falling Step Size fields are similar to the Profile Registers; upon default, they are set up for frequency inputs, but these boxes can be changed to intake phase or amplitude information by selecting the type of linear sweep desired in the Modulation Output Type list in the Channel Control window. Figure 28. In the linear sweep mode of operation, only the first Profile Register field (Frequency 01, Phase 01, or Amplitude 01) is used. It indicates the ending point of the sweep. In Figure 28, the frequency linear sweep begins at 10 MHz and ends at 50 MHz. 3. The number of steps in a ramp can be calculated by determining the difference between the starting and ending points of the sweep and dividing by the step size. The time required to sweep is then the number of steps times the amount of time spent at each step. Profile and RURD Pin Control Profile and RURD Pin Control cover the profile pins (P0, P1, P2, and P3) and SDIO data pins (SDIO1, SDIO2, and SDIO3). The profile pins can be configured to control modulation, linear sweep, or RU/RD operations, whereas the SDIO data pins can only control the RU/RD operation. To perform the desired modulation, linear sweep, or RU/RD operation, toggle the profile/SDIO data pin(s) associated with that operation. When these pins are pressed, they are set to Logic 1 (see Figure 29). The range of the Rising/Falling Step Interval is computed similarly to the time range for the Amplitude Ramp Rate. Note that the Rising Step Interval and Falling Step Interval boxes also have the pop-up window feature exhibited in Figure 25 when the maximum rising/falling step interval value is exceeded. For more information regarding the Linear Sweep Setup, refer to the Setting the Slope of the Linear Sweep section of the AD9958 data sheet. 05783-029 Debug Figure 29. Upon default, the Auto check box is selected, meaning that once you click one of the pins (profile or SDIO), the action executes. If this box is deselected, the Apply button must be clicked before the desired action is carried out. The Apply button mimics the LOAD button; it flashes orange when new data is detected, but all changes and updates occur simultaneously when Apply is clicked. The Debug window, shown in Figure 30, lets you write directly to any of the AD9958’s internal registers and subsequently read them back. Use View Channel to select which channel’s internal registers you would like to view. The default setting of this box is Channel 0. To access the internal registers of the selected channel, use the RegAddr drop menu to select which register(s) you would like to read/write. You can also directly toggle the states of any external input pins such as the profile or SDIO data pins. Rev. 0 | Page 15 of 28 AD9958/PCB DUT I/O Box 05783-030 This dialog box (Figure 32) controls the I/O configuration for the device. Click I/O Reset to send an I/O reset to the corresponding serial port state machine. Select LSB First to change the data format to LSB first from the default setting of MSB first. Use the Serial I/O Mode drop-down list to select the desired serial I/O mode of operation: Single Bit-2 Wire (default), Single Bit-3 Wire, 2-Bit Serial, or 4-Bit Serial. For more information, please refer to the Serial I/O Modes of Operation section of the AD9958 data sheet. Figure 30. 05783-032 To access the Debug window, click View > Debug Window (see Figure 31). 05783-031 Figure 32. To access the DUT I/O dialog box, click the I/O menu (left of view—see Figure 31) and select DUT I/O. Figure 31. Rev. 0 | Page 16 of 28 AD9958/PCB SETUP FILES Introduction The AD9958 can be configured to perform many operations in various combinations. Preconfigured setup files have been included with the AD9958 evaluation software that show the device in all three modes of operation: single tone, modulation, and linear sweep. These example setup files serve as a reference and/or starting point when trying to configure the device for a desired setup for the first time. 05783-033 05783-034 To load these setup files click File > Load Setup (Figure 33), or click the Load Setup File icon (Figure 34) to access these files. Figure 34. Figure 33. 05783-035 Next, open the AD9958 Configuration Files folder (Figure 35). Figure 35. 05783-036 Then select which mode of operation setup file(s) you would like to view (see Figure 36). Select Linear Sweep Mode, Modulation Mode, or Single Tone Mode. Figure 36. Rev. 0 | Page 17 of 28 AD9958/PCB Single Tone Mode Open the Single Tone Mode folder to access the single tone mode of operation example setup files. This section discusses the Both Channels on @30_40MHz_RURD enabled.stp file. 05783-037 The Chip Level Control window (Figure 37) from this particular setup shows that a 500 MHz System Clock is running, with the RU/RD operation enabled. In the RU/RD list, Use Profile Pins 2 & 3 has been selected to control the RU/RD feature. Figure 37. 05783-038 In the Channel Control window (Figure 38), each channel has None (Single Tone) selected for their modulation output as shown in the Modulation Output Type list. Figure 38. Rev. 0 | Page 18 of 28 AD9958/PCB 05783-039 In the Channel Output Config window (Figure 39), Channel 0 has a frequency output of 30 MHz (Frequency 00 box) and Channel 1 an output frequency of 40 MHz. Because the RU/RD operation is enabled, the Enable ASF and Enable Auto ASF check boxes are selected. The amplitude scalar factor (ASF) is set to 1 (full scale). Therefore, the output signal is 0 MHz until the correct profile pin is selected to ramp the frequency up to full scale. When this setup file is loaded, Profile Pin P2 and Profile Pin P3 are pressed as shown in Profile and RURD Pin Control. P2 controls Channel 0 and P3 controls Channel 1. If a profile pin is deselected, the associated channel’s output returns to 0 MHz. To return to full scale, re-press the profile pin that triggers the RU/RD operation. Figure 39. Modulation Mode 05783-040 Open the Modulation Mode folder to access the modulation mode of operation example setup files. Once this folder is opened you are presented with the window shown in Figure 40. Figure 40. For frequency modulation (FSK), open the Frequency folder; for phase modulation (PSK), open the Phase folder; and for amplitude modulation (ASK), open the Amplitude folder. In these folders, all setup files are indexed by their level (2-, 4-, 8-, or 16-level). This section discusses the CH0_@3 MHz increments.stp file found in the Frequency folder under the 16-level folder. Rev. 0 | Page 19 of 28 AD9958/PCB 05783-041 The Chip Level Control window (Figure 41) from this particular setup shows that a 500 MHz System Clock is running, and that a 16level modulation-no RU/RD is being performed. Notice the Level list located in Modulation Configuration. The PPC Bit pattern in the Profile Pin Config of Modulation Configuration is <010>. Referring to the table in the 16-Level Modulation—No RU/RD section of the AD9958 data sheet, you see that this bit pattern sets up 16-level modulation on Channel 0. Figure 41. 05783-042 In the Channel Control window (Figure 42), Channel 0 has Frequency selected as its modulation output as shown in the Modulation Output Type list. As discussed in the Channel Constraint Guidelines section of the AD9958 data sheet, when performing 16-level modulation on a selected channel, all other channels are available only for the single tone mode of operation. Figure 42. Rev. 0 | Page 20 of 28 AD9958/PCB 05783-043 In the Channel Output Config window (Figure 43), Channel 0 has a frequency output of 3 MHz (Frequency 00 box). When this setup file is loaded, Profile Pin P1 and Profile Pin P3 are pressed as shown in Profile and RURD Pin Control. In 16-level modulation, P3 is the LSB and P0 is the MSB. This explains why when this setup file is loaded, an output of 18 MHz is shown because 0101 binary = 5, and Profile Register 05 contains 18 MHz as its output. If no profile pins are selected, the output frequency is equivalent to the value entered in the Frequency 00 box (3 MHz in this setup). If all profile pins are pressed, the output frequency is equal to 48 MHz, the contents of Profile Register 15 (1111 binary). Figure 43. Linear Sweep Mode 05783-044 Open the Linear Sweep Mode folder to access the linear sweep mode of operation example setup files. Once this folder is opened you are presented with the window shown in Figure 44. Figure 44. For a frequency sweep, open the Frequency folder; for a phase sweep, open the Phase folder; and for an amplitude sweep, open the Amplitude folder. This section discusses the Both Channels@10MHz_half to full scale.stp file found in the Amplitude folder. Rev. 0 | Page 21 of 28 AD9958/PCB 05783-045 The Chip Level Control window (Figure 45) from this particular setup shows that a 500 MHz System Clock is running with RU/RD disabled. The Auto Clear Phase Accumulator and Auto Clear Sweep Accumulator check boxes have been selected in All Channel Accumulator Control to ensure synchronization across channels and reinitialize the starting point once the linear sweep ends. Figure 45. 05783-046 In the Channel Control window (Figure 46), each channel has Amplitude selected for its modulation output as shown in the Modulation Output Type list. As discussed earlier in the Linear Sweep Options section, the Enable Linear Sweep check box found in Linear Sweep Options must be selected in order to configure the part for the linear sweep mode of operation. Figure 46. Rev. 0 | Page 22 of 28 AD9958/PCB 05783-047 In the Channel Output Config window (Figure 47), both channels (Channel 0 and 1) have an output frequency of 10 MHz (Frequency 00 box). The Enable ASF check box is deselected because a linear amplitude sweep is being performed. The amplitude scalar factor (ASF) is set to 0.5 (half scale), denoting that the sweep begins at half scale and sweeps up to full scale (Amplitude 01-ending point of sweep). In Linear Sweep Setup, the rising/falling step size and step intervals of the sweep are equal, indicating the sweep rises and falls at the same rate. P2 controls Channel 0 and P3 controls Channel 1. To sweep up to full scale, press the profile pin associated with the channel’s output. To return to half scale, unselect the profile pin. Figure 47. Rev. 0 | Page 23 of 28 Figure 48. AD9958/PCB Schematic, Page 1 R59 0Ω R56 0Ω GND BG_VDD GND C62 0.1µF C55 0.1µF C65 0.1µF GND CLK_VDD GND GND AVDD3 GND C54 0.1µF DVDD_IO C56 0.1µF AVDD2 AVDD1 DVDD C50 0.1µF GND C53 0.1µF R50 0Ω C49 0.1µF C44 0.1µF C46 0.1µF C52 0.1µF GND DAC3_OUT C48 0.1µF C45 0.1µF C51 0.1µF C57 0.1µF 1 6 ADTT1-1 2 T5 5 4 3 1 ADTT1-1 6 DAC1/AD9958 DAC3/AD9959 GND 2 3 5 4 T4 DAC0/AD9958 DAC2/AD9959 AVDD1 DAC2_OUT R60 0Ω R57 0Ω R63 0Ω BYPASS CAPACITORS R61 0Ω R58 0Ω R62 0Ω GND AVDD0 AVDD3 AVDD2 AVDD3 AVDD2 R64 0Ω AVDD2 AVDD0 AVDD1 AVDD3 AVDD0 R7 50Ω AVDD3 R8 50Ω AVDD0 AVDD1 R5 50Ω AVDD2 R6 50Ω AVDD1 J12 SYNCOUT U10 GND 14 13 11 12 10 9 7 8 6 5 3 4 2 1 J9 REF CLK GND GND 6 4 5 U10 74LVC125A P2 D2_DGND D2_AVDD 1.91kΩ R11 D3_IOUT D3_IOUTB D3_DGND D3_DVDD D2_IOUTB D2_AGND 4 T1 SEC 3 GND R31 25Ω R10 50Ω R30 25Ω GND 0.1µF C22 0.1µF C21 GND C66 39pF 0Ω R52 x2 2 0Ω R53 25MHz 1 698Ω R9 GND 29 30 32 31 33 34 36 35 37 38 40 39 41 42 GND AVDD0 GND GND AVDD0 AVDD1 GND AVDD1 P1 P0 P2 R2 50Ω R4 50Ω AVDD0 AVDD0 R3 50Ω AVDD0 AVDD1 AVDD1 R1 50Ω AVDD1 T2 4 5 6 J10 J20 J16 GND DVDD_IO GND DAC1_OUT GND DAC0_OUT DAC0/AD9959 T3 ADTT1-1 3 2 1 4 5 6 DAC1/AD9959 GND + BG_VDD AVDD3 AVDD0 C35 10µF C64 10µF GND + ADTT1-1 3 2 1 C36 10µF GND + VCC_USB J18 J17 GND C69 10µF NOTE THE D0 AND D1 PINS ARE ONLY USED FOR THE AD9959, WHICH HAS DAC0, DAC1, DAC2, AND DAC3. THE AD9958 USES THE D2 PINS FOR DAC0 AND THE D3 PINS FOR DAC1. C67 39pF 680pF C38 D0_IOUT D0_IOUTB D0_AVDD D0_DGND D1_AGND D0_DVDD D1_IOUTB D1_AVDD D1_IOUT D2_DVDD D2_IOUT D1_DVDD D1_DGND PWR_DWN P1 P0 U3 AD9958/ AD9959 J13 SYNC CLK SYNC_OUT RESET SYNC_IN J11 ETC1-1-13 5 1 PRI CLK_VDD GND W11 CLK_MODE_SEL GND AVDD3 GND AVDD2 AVDD2 GND PWR_DWN RESET GND 1 74LVC125A 3 2 SYNCIN 56 15 D3_AVDD D3_AGND 16 17 AVDD3 GND AVDD1 SYNC_CLK 18 GND R51 0Ω BG_VDD GND R54 0Ω CLK_VDD R21 0Ω 19 BG_VDD CLK_GND 20 21 CLK_VDD 22 R55 0Ω GND REF_CLKB 23 REF_CLK CMS 24 25 CLK_MODE_SEL AVDD0 SDIO_3 GND DVDD 55 54 DGND1 DVDD1 SDIO_3 53 SYNC_CLK DAC_RSET SDIO_2 SDIO_1 52 BG_GND SDIO_0 51 50 SDIO_2 SDIO_1 DVDD_IO SCLK 49 SDIO_0 CSB 48 47 DVDD_IO SCLK IO_UPDATE IO_UPDATE 26 CLK_VDD AVDD0 DVDD GND PLL/DLL_VDD LOOP_FILT 46 CS DVDD GND 45 PLL/DLL_GND P3 44 43 P3 D0_AGND 27 28 Rev. 0 | Page 24 of 28 GND + C68 10µF 4 3 2 1 C47 10µF C37 10µF DVDD GND DVDD_IO VCC_USB GND + CLK_VDD AVDD3 AVDD2 DVDD C63 10µF GND + GND + TB1 + C58 10µF GND + 05783-051 J19 AD9958/PCB SCHEMATICS Figure 49. AD9958/PCB Schematic, Page 2 Rev. 0 | Page 25 of 28 J8 DAC 1/AD9958 DAC 3/AD9959 DUT FILTER OUT J7 DAC 0/AD9958 DAC 2/AD9959 DUT FILTER OUT GND GND GND GND C12 _F GND C14 _F C72 _F C71 _F _F GND C73 _F L6 C79 L5 C70 C75 _F _F L4 C74 _F GND _F GND GND 200MHz LOW-PASS FILTER C78 C76 _F C13 _F _F _F L3 C20 _F L2 C11 C16 _F L1 C15 _F GND C19 C17 _F GND 200MHz LOW-PASS FILTER GND GND GND GND C80 _F C77 _F C60 _F C18 _F 0Ω R27 0Ω R27 DAC2_OUT R26 0Ω DAC3_OUT J4 DAC 1/AD9958 DAC 3/AD9959 DUT OUT/FILTER IN R28 0Ω J3 DAC 0/AD9958 DAC 2/AD9959 DUT OUT/FILTER IN J6 DAC 0 DUT FILTER OUT J5 DAC 1 DUT FILTER OUT GND GND GND GND C6 _F C3 _F L11 _F GND L7 C82 _F _F C90 C85 _F GND GND C84 _F GND GND C5 _F C1 _F _F C10 L10 GND GND C7 _F C2 _F L12 _F C9 L9 _F C81 C86 _F 200MHz LOW-PASS FILTER C34 C83 _F L8 _F C89 C87 _F GND 200MHz LOW-PASS FILTER GND GND GND GND C8 _F C4 _F C91 _F C88 _F 0Ω R25 0Ω R22 DAC1_OUT J1 R24 0Ω DAC0_OUT J2 DAC 0/AD9959 DUT OUT/FILTER IN R23 0Ω DAC 1/AD9959 DUT OUT/FILTER IN 05783-052 GND AD9958/PCB AD9958/PCB I/O HEADERS U13 1 3 5 7 9 11 13 15 17 19 21 23 25 PWR_DWN_U RESET_U SCLK_U CSB_U IO_UPDATE_U IP3_U P2_U P1_U P0_U R71 GND SDIO_0 P1 P3 P5 P7 P9 P11 P13 P15 P17 P19 P21 P23 P25 U2 2 4 6 8 10 12 14 16 18 20 22 24 26 P2 P4 P6 P8 P10 P12 P14 P16 P18 P20 P22 P24 P26 R67 R66 R29 R65 GND GND GND GND 1kΩ 1kΩ 1kΩ 1kΩ 1kΩ P0 P1 P2 P3 IO_UPDATE CSB SCLK RESET PWR_DWN SDIO_3 1kΩ SDIO_2 1kΩ SDIO_1 1kΩ R68 R69 R70 GND GND GND 1 3 5 7 9 11 13 15 17 19 21 23 25 P1 P3 P5 P7 P9 P11 P13 P15 P17 P19 P21 P23 P25 2 4 6 8 10 12 14 16 18 20 22 24 26 P2 P4 P6 P8 P10 P12 P14 P16 P18 P20 P22 P24 P26 GND I/O BUFFERS GND R13 50Ω P3_U P2_U P1_U P0_U U12 1 3 2 RURD_0_U RURD_1_U RURD_2_U 74LVC32A I/O_UPDATE_U USB_STATUS 1 4 R15 2 CR2 GND GND 800Ω RURD_0_U RURD_1_U RURD_2_U GND GND C40 22pF C39 22pF x1 1 VCC_USB GND 2 24MHz VCC_USB U7 VBUS D– USB_HDR D+ GND SHIELD0 SHIELD1 1 VBUS 2 3 4 5 6 GND 4 GND VCC_USB C92 4700pF R20 1MΩ R18 2.2kΩ GND GND GND1 VCC_USB GND TP GND R19 2.2kΩ VCC_USB SDIO_0 SDIO_1 SDIO_2 SDIO_3 U8 1 2 3 NC1 VCC NC2 NC3 VSS NC4 SCL SCA 8 7 6 PWR_DWN_U RESET_U SCLK_U CSB_U P3 P2 P1 P0 IO_UPDATE RURD_0 RURD_1 RURD_2 15 16 17 18 CR1 VCC_USB VCC_USB GND GND:10 11 12 13 14 1 19 W7 U6 VCC_USB:20 OE1 OE2 74LVC541A 9 Y7 A7 8 Y6 A6 7 Y5 A5 6 Y4 A4 5 Y3 A3 4 Y2 A2 3 Y1 A1 2 Y0 A0 GND:10 11 12 13 14 15 16 17 18 VCC_USB W10 W1 W2 W4 RURD_0 RURD_1 SCLK CSB VCC_USB PD4/FD12 PD3/FD11 PD2/FD10 PD1/FD9 PD5/FD13 PD6/FD14 PD7/FD15 GND1 CLKOUT VCC1 3 4 5 6 7 8 GND2 ADY0/SLRD RDY1/SLWR AVCC XTALOUT XTALIN AGND 9 10 11 12 13 14 15 PD0/FD8 WAKEUP VCC7 RESET GND6 PA7/FLAGD/SLC5 PA6/PKTEND VCC2 DPLUS DMINUS GND3 VCC3 GND IFCLK 16 17 18 19 20 21 22 RESERVED SCL SDA VCC4 PB0/FD0 PB1/FD1 PB2/FD2 23 24 25 26 27 28 PA5/FIFOADR1 PA4/FIFOADR0 PA3/WU2 PA2/SLOE PA1/INT1 PA0/INT0 VCC6 CTL2/FLAGC CTL1/FLAGB CTL0/FLAGA GND5 VCC5 GND4 PB7/FD7 PB6/FD6 PB5/FD5 PB4/FD4 PB3/FD3 56 55 54 53 52 51 50 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32 31 30 29 R12 100kΩ IO_UPDATE_U P3_U P2_U P1_U C43 10µF P0_U GND VCC_USB VCC_USB GND R17 100kΩ PWR_DWN_U RESET_U CSB _U USB_STATUS C41 1µF GND VCC_USB SCLK_U GND VCC_USB GND CY7C68013 R14 2.2kΩ W6 W9 24LC00 1 2 W3 5 PWR_DWN RESET U4 74LVC14A R16 VBUS OE1 OE2 74LVC541A 9 Y7 A7 8 Y6 A6 7 Y5 A5 6 Y4 A4 5 Y3 A3 4 Y2 A2 3 Y1 A1 2 Y0 A0 GND 300Ω 74LVC14A VCC_USB VCC_USB:20 USB I/O U9 U9 U5 1 19 I/O UPDATE OUT J15 PC_CTRL PC_CTRL I/O UPDATE IN J14 3 GND W5 GND RURD_2 USB BYPASS CAPACITORS VCC_USB VCC_USB C24 0.1µF C25 0.1µF C26 0.1µF C27 0.1µF C28 0.1µF C29 0.1µF C30 0.1µF C31 0.1µF C32 0.1µF C33 0.1µF C23 0.1µF C59 0.1µF C42 2.2µF C61 0.1µF GND CLK_VDD AVDD3 R36 0Ω BG_VDD R37 0Ω R35 0Ω R33 0Ω R34 0Ω AVDD0 R38 0Ω R32 0Ω R39 0Ω R40 0Ω R41 0Ω R42 0Ω R43 0Ω BG_VDD R44 0Ω CLK_VDD Figure 50. AD9958/PCB Schematic, Page 3 Rev. 0 | Page 26 of 28 R45 0Ω R46 0Ω R47 0Ω R48 0Ω R49 0Ω 05783-053 GND AD9958/PCB ORDERING INFORMATION ORDERING GUIDE Model AD9958/PCB Description Evaluation Board ESD CAUTION ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on the human body and test equipment and can discharge without detection. Although this product features proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance degradation or loss of functionality. Rev. 0 | Page 27 of 28 AD9958/PCB NOTES ©2006 Analog Devices, Inc. All rights reserved. Trademarks and registered trademarks are the property of their respective owners. EB05783-0-1/06(0) Rev. 0 | Page 28 of 28