Document 11886357

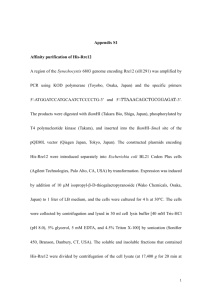

advertisement