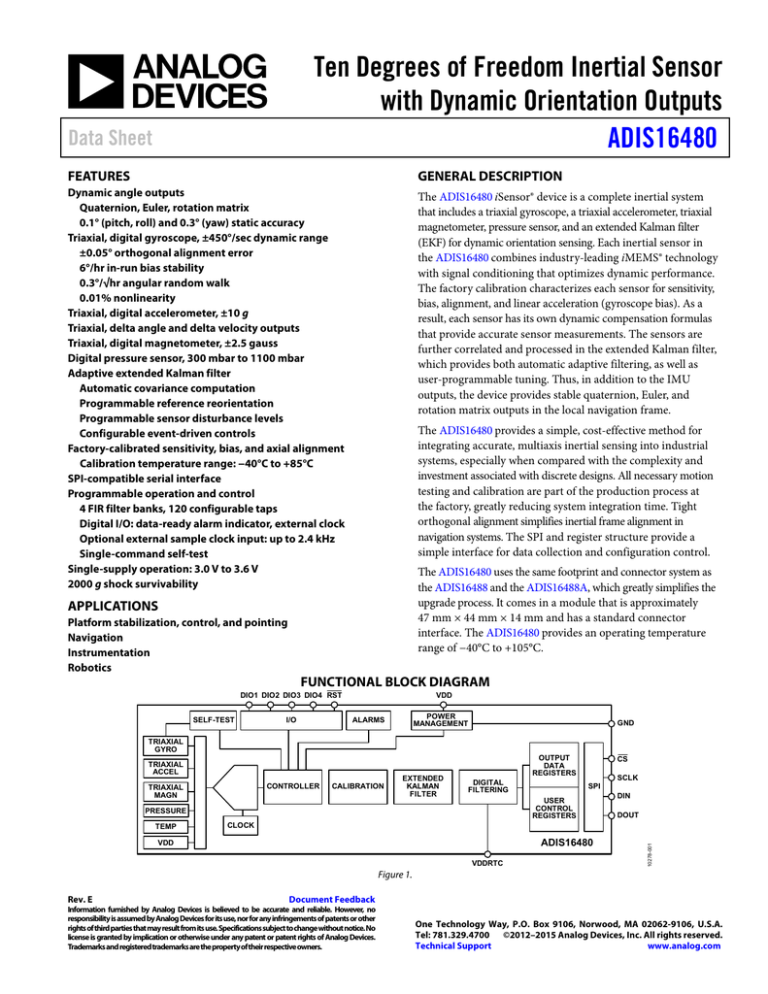

Ten Degrees of Freedom Inertial Sensor with Dynamic Orientation Outputs ADIS16480 Data Sheet

advertisement