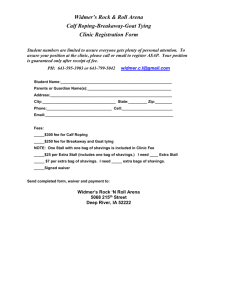

Silver Dollar Racing & Shavings Joshua & Krystal Harty Mar 31, 2016 1

advertisement

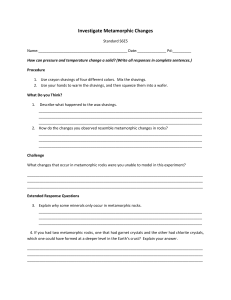

Silver Dollar Racing & Shavings Joshua & Krystal Harty Mar 31, 2016 1 Agenda • • • • • • Background Business Timeline Maxwell, NM Mill History and Setup Current Process and Products Challenges and Solutions Questions 2 Background • Cody and Kathy Deines – race horse trainers and ranchers • Joshua Harty – farmer, professional welder, and mechanic • Krystal Harty – mechanical and aerospace engineering 3 Business Timeline • 1984 – Silver Dollar Racing was started and idea for shavings business born o Wood shavings used in stalls at the track, replacing straw o Shavings were hard to come by • 1993 – Shavings delivery started and name was changed to Silver Dollar Racing & Shavings o Bought and rebuilt old dump trailer and 4x4 pickup o Bought shavings from wood businesses and started delivering to the track o Helped prevent businesses having to get rid of shavings that eventually ended up in a landfill or burner 4 Business Timeline – cont’d • 1994 – Delivery increased o Race horse training took a back seat o Delivering to ~20-25 regular customers in Albuquerque and surrounding area o Customers included Arabian, show, cutting, and boarding facilities • 1997 – Work loads increased o Kathy started working for Silver Dollar Racing & Shavings full time o Started buying equipment for bagging bulk shavings • Partnered with White Sands Forest products in Alamogordo • Delivered semi loads to New Mexico, Arizona, Texas and Oklahoma 5 Business Timeline – cont’d • 1998-2000 – Bagging facility in Albuquerque, NM o Bought out HCS, Inc. (one of Silver Dollar Racing and Shavings’ largest competitors) o Gained more customers (over 300) in the Albuquerque/ Santa Fe area o Sold retail portion in July 2000 • 2000-2001 – Moved to Maxwell, NM o Bought acreage in Maxwell, NM o Kathy became Board of Director and Secretary/Treasurer of the Cimarron Watershed Alliance (CWA) • 2003 – Maxwell, NM mill procurement 6 Maxwell, NM Mill History • Built in the late 1800s • Used as a sugar beet facility, turkey processing plant, feed mill and more 7 Maxwell, NM Mill History cont’d • Used for junk storage since 1960s • Silver Dollar Racing & Shavings cleaned and improved the facility 8 Maxwell, NM Mill Setup Foundation Equipment Electricity Equipment Equipment 9 Process 1 2 3 Shaver to storage bin Storage bin to dryer Dryer to screen* 1 2 3 *Oversized pieces chopped up and sent to the top of the screen. Undersized pieces go to the biomass burner for fuel. 100% of log is used!!! 10 Process cont’d 4a 4b 5a 5b Screen to yellow storage bin Screen to wattle storage bin Yellow storage bin to bagger Wattle storage bin to extruder (inside building) 5a 4a 4b 5b 11 Current Expansion • Improving wood wattle production o Will increase ability to utilize more small diameter wood from forest thinning projects o Will introduce a new product to customers that utilizes wood as opposed to straw Wood Wattle extruder Wood Wattle in use 12 Products Bagged Shavings Wood Wattles 13 Challenges • Employee hiring and retention in a small town o Reduced industry and economic growth in rural areas has made good employees hard to find o Training can be extensive/expensive for some positions and retention is important but challenging • Surviving economic downturns o Market volatility challenges small business • Log availability and transportation o Limited logging in the area (even though plenty of acres need treatment) o Transportation is expensive o Very few contractors are available for hauling 14 Solutions • Employee hiring and retention in a small town o Providing a comfortable work environment o Paying above average salaries for the area • Surviving economic downturns o Managing expenses • Log availability and transportation o Getting involved in forest restoration projects o Collaborating with other businesses in the area o Hauling our own logs 15 Proud of our business Since Jan 1, 2015, we have utilized 6,580 tons of logs and injected approximately $145,000 into restoration projects 16 Thank you!!!! Questions? 17