Naval Postgraduate School December 2006

advertisement

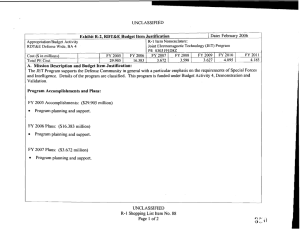

Naval Postgraduate School December 2006 LT Jesse Black, USN LT Scott Bailey, USN LT Daniel Kidd, USN LT Todd Greene, USN LT Randy Slaff, USN LCDR Orlando Cornejo, CHL LT Rami Ramdat, USN LCDR Jason Stracqualursi, USN LT Brian Rosemark, USN LTjg Alexandros Dendis, GRE LT Martin Holguin, USN Outline • • • • • • • • • • Systems Engineering Overview Power Plant Electrical Plant Hull and Mechanical EP Thermal Management Combat Systems H&M Manning Cost T Risk Management Building Bridges Final Brief 06 SE PP BB R $ CS M Unclassified 2 Sensor Architecture • • • • Multi-layered Ballistic Missile Defense Sensor Systems Wide-range of multi-spectrum sensors to detect and track threat missiles through all phases of their trajectory Space and Satellites Tracking Surveillance Systems Land-and sea-based early warning and forward deployable radar systems. Final Brief 06 Unclassified 3 Stand-alone Configuration • Considerations for stand-alone configuration using onboard ship-borne sensor systems: – Conformable aperstructure, skin of the ship (SOTS) radar, exploits the entire ship’s structure as a radar aperture – Multifunction phased array radar (MFPAR), with dedicated Search, Track and Fire Control functions Final Brief 06 Unclassified 4 What is a Railgun? • Conventional launching method uses mechanical and chemical energy. • Railgun launching utilizes electromagnetic force for propelling projectile. – Higher muzzle velocity. – Higher kinetic energy delivered to the target. Final Brief 06 Unclassified 5 Railgun Theory • • • Electromagnetic force - Lorentz force The current flowing through the rails sets up a magnetic field. Results in a mutual repulsion of the rails and the acceleration of the projectile. Adapted: Exploring the possibilities of a Naval Electromagnetic Railgun (38th Annual Gun and Ammunition Symposium Final Brief 06 Unclassified 6 Railgun Advantages • High Impact Energy • Size / Weight / Space • No explosives • Extremely High Speed / Range • Interaction of KE penetrator with the missile / High shock Transmission • Adiabatic heating and ignition causing explosion and deflagration 2.2MJ • Scale up / down • Less Recoil Final Brief 06 1 2 KE mv 2 Current Capabilities • Sandia National Research Laboratories – Launcher: 6 mm – Mass of object: 0.1 gram – Speed: 16000 m/s / 57600 km/h / Mach 48 – Energy: 12.8KJ • Maxwell Laboratories – – – • Electromagnetic Launcher - Kirkcudbright, Scotland – – – • Speed: 2500 m/s / 9000 km/h / Mach 7.5 Range: Beyond 200 nautical miles / 370 km Power requirement: 15 ~ 30 MJ University of Texas – Institute of Advanced Technology – – – – Final Brief 06 Mass of projectile: 1.6 kg Speed: 3300 m/s / 11880 km/h / Mach 10 Energy: 9 MJ Flight mass: 15kg Muzzle Velocity: 2500 m/s Range: Beyond 270 nautical miles / 500 km Impact Velocity: 1600 m/s Unclassified 8 Projected Capabilities • Flight Mass : 3.5 kg • Launch Velocity: 6 km/sec • Guided • Range: beyond 4400 km 12 • Firing Rate: 16 to 20 RPM • Cost: ~ $60k per round Adapted: Exploring the possibilities of a Naval Electromagnetic Railgun (38th Annual Gun and Ammunition Symposium) Final Brief 06 Unclassified 9 Contract Between TSSE and SEA09 • Formalize the shareholder system expectations • Define the preferred system architecture, including threshold and optimal levels of performance • Handoff between SEA-9 and TSSE-BMD Final Brief 06 Unclassified 10 Spiral Model of the Defense System Life Cycle From Kossiakoff & Sweet Final Brief 06 Unclassified 12 Questionnaire Final Brief 06 Unclassified 13 AoA Traceability Final Brief 06 Unclassified 14 AoA Traceability Example (Hullform) Final Brief 06 Unclassified 15 Systems Engineering (Essentials of Project & Systems Engineering Management [Eisner 97]) Customer & User Req’ts Project Plan Functional Design of Alternatives Analysis of Alternatives Preferred System Architecture N Architecture Design Satisfies Req’ts? Evaluation Criteria Y Subsystem design/ Subsystem System Integration Design Analysis of Alternatives Trade-off Studies Preferred Sub-system designs N Satisfies Req’ts? System Construction Y Subsystem build Final Brief 06 Sub-system Test Sub-system Integration System Test & Evaluation Cost effective physical system Unclassified 16 Outline • • • • • • • • • • Systems Engineering Overview Power Plant Electrical Plant Hull and Mechanical EP Thermal Management Combat Systems H&M Manning Cost T Risk Management Building Bridges Final Brief 06 SE PP BB R $ CS M Unclassified 17 Power Plant AOA Recap • Initial propulsion AOA last quarter • Resulting winners: Molten Salt (Liquid Fluoride) & Gas Turbine • Main reasons: Low Manning, Low Weight • Other nuclear options considered were HPW and Lead Cooled • Required a ‘second round’ Final Brief 06 Unclassified 18 Excel Cost Analysis of Propulsion “Finalists” • Cost of fuel increase above inflation (inflation frozen model) • Compares projected costs of Gas Turbine and Liquid Fluoride Reactor • All initial conditions user-adjustable via scrollbars. • Resulted in final choice of Reactor over Gas-Turbine Final Brief 06 Unclassified 19 What is a Liquid Fluoride (Molten Salt) Reactor? • Liquid-core vice solid core (7LiF-BeF2-233UF4) • Utilizes Thorium fission cycle • High Negative Temperature coefficient • Passively safe • Currently being considered under GEN-IV Initiative Final Brief 06 Thorium Fuel Cycle Final Brief 06 Unclassified 21 Advantages • • • • High Thermal Efficiency (700ºC-Closed Loop Gas Turbine) Allows Online Reprocessing/Thorium Fuel Cycle Available research from ORNL No NOFORN Restrictions Disadvantages • • • • Material science research required for Naval application Potential Tridium leakage into He Reprocessing required for Thorium Current Funding for GEN-IV Initiative low Final Brief 06 Unclassified 22 NASA Assistance •Kirk Sorensen assisted with “Sigma-1” Reactor design 14-15 Aug 06 • Member of In-Space Propulsion Technology Projects Office, NASA Marshall Space Flight Center • Collated data from many NASA and outside sources regarding this particular reactor design, including: → Dr. Albert J. Juhasz, Brayton Systems Analysis, NASA Glenn Research Center, Electromechanical Systems Branch → Dr. Per F. Peterson, Department of Nuclear Engineering, University of California Berkeley → Oak Ridge National Labs data regarding the Molten Salt Reactor Experiment (MSRE) • Author of “Energy from Thorium” weblog, http://thoriumenergy.blogspot.com/ • Currently a Masters Student in Nuclear Engineering, University of Tennessee Final Brief 06 Unclassified 23 2 Reactor Coupling to Brayton-Cycle Turbine 1 3 F Salt/Helium Heat Exchanger D 4 6 5 7 B Helium/SW Heat Exchanger E 1 2 HP Heat Exchanger HP Turbine 3 MP Heat Exchanger 4 MP Turbine C 5 A LP Heat Exchanger 6 LP Turbine F Regenerator 7 HP Compressor Final Brief 06 E HP Heat Exchanger D MP Compressor C MP Heat Exchanger B A LP Heat LP Exchanger Compressor Unclassified 24 Collaborations • NASA and Ohio State to Work on Complete Nuclear Plant Design • Cleveland State To Work on Complete Secondary Plant Design Final Brief 06 Unclassified 25 Outline • • • • • • • • • • Systems Engineering Overview Power Plant Electrical Plant Hull and Mechanical EP Thermal Management Combat Systems H&M Manning Cost T Risk Management Building Bridges Final Brief 06 SE PP BB R $ CS M Unclassified 26 Electric Plant Combat Load PULSED ALTERNATORS FW 50MW SHORE PWR 50MW RG HPM 50MW HPM 50MW 50MW FW SS Load RG SHORE PWR 50MW SS Load Combat Load 2500 VDC Final Brief 06 Unclassified 27 Outline of an Integrated DC Power Distribution System DC-AC Inverter 800 vdc – 450 vac DC-DC Buck Converter 1500-800 vdc 2000-800 2500 Ship Service Propulsion TURBINE Final Brief 06 RECTIFIED ALTERNATOR 1500 vdc 2000 2500VDC 0-600 vdc Buck Converter DC - DC Superconducting DC Homopolar Motor Unclassified 28 Range of Use Product Range DURESCA® and TIRESCA® for outdoor and indoor application Nominal voltage in “kV” 245 170 50MW/2500V=20000A 20000A/5000A=4 145 123 DURESCA® Solid- and fully insulated busbars 72.5 52 4 cables in parallel 36 24 TIRESCA® Solid- and partially insulated busbars 17.5 12 1 0 0 630 1000 800 1600 1250 2500 2000 3800 3150 5400 4600 8500 7500 Nominal current in “A” Final Brief 06 Unclassified 29 High Power Busbars Protection tube DURESCA® busbars TIRESCA® busbars Protection tube Protection tube - corrugated polyamide tube (UV-stable) or aluminum or corrugated stainless steel tube for high strength Insulation Insulation Vacuum dried Epoxy Resin Impregnated paper Void free Conductor tube or rod Partial discharge free (1.5 x rated voltage) down to 2pC Ground shield aluminum foil with copper braid (> 8 kA) Conductor Conductor - high conductive aluminum (or copper) rod or tube Final Brief 06 Unclassified 30 Building Bridges • CEM - Electric Plant Scenario • NASA Power Systems - Fly Wheel Design • Northrop Grumman - Electrical Distribution • American Superconductor New Generator Sets • General Atomics – Homopolar Podded Propulsor Final Brief 06 Unclassified 31 Outline • • • • • • • • • • Systems Engineering Overview Power Plant Electrical Plant Hull and Mechanical EP Thermal Management Combat Systems H&M Manning Cost T Risk Management Building Bridges Final Brief 06 SE PP BB R $ CS M Unclassified 32 The HM&E Design Spiral CAPACITIES TRIM & INTACT STABILITY Final Brief 06 Unclassified 33 Preliminary Estimates • Based on requirements & parametric studies Parametric Analysis Stakeholder Requirements Given Ship Specifics: Displacement Sustained Speed Density (salt water) Acceleration of gravity 15,000.0 30.0 50.0 35.0 32.2 LT knots ft/s cuft/LT ft/s^2 525,000 650 55 1.18 0.35 1.91 650 0.60 0.72 3.0 0.43 25.0 74.9 8.7 cuft ft Starting-point hull particulars Estimated Ship Characteristics: 1 2 3 4 5 6 7 8 9 10 11 12 Solutions: Volume Displaced Length (LWL) (initial estimate) Displacement to Length Speed-to-Length ratio (Taylor Quotient) Froude Number Volumetric Coef. (Fatness Ratio) Length (revised estimate) Prismatic Coefficient Midship Section Coefficient Beam-to-Draft Ratio Block Coefficient Draft Beam Length-to-Beam Ratio Final Brief 06 Typical values: 40 to 100 0.4 to 2.0 0.12 to 0.60 1.0 to 7.0 ft (from chart) 0.60 to 0.99 2.8 to 3.8 ft ft 7.5 to 10 Unclassified 34 Lines & Body Plan • Based on parametric values – Displacement, draft, beam, Cb, Cp, Cx • Constructed in Rhino – Hydrostatics calculated with RhinoMarine Final Brief 06 Unclassified 35 • Focused on underwater hull form matching parametric values Final Brief 06 Unclassified 36 First Iteration Particulars Final Brief 06 LOA 645 ft LWL 632 ft Beam 79 ft Draft 24.2 ft Displacement 15260 tons Cb .437 Cx .721 Cp .606 Unclassified 37 Powering • How much power is needed for propulsion? – Speed requirement based on operations – Resistance estimates • How to best transmit the power into the water – Propulsion AoA – Propeller design Final Brief 06 Unclassified 38 Power Requirements 50000 V (knots) EHP (hp) 3.00 70.10 6.00 512.33 9.00 1300.20 12.00 2936.67 15.00 5556.96 18.00 9489.15 21.00 15173.66 24.00 23049.52 10000 27.00 32487.00 5000 30.00 45921.53 45000 Total required power (with and without estimated appendages) 40000 -----Autopower -----PPP -----Navcad -----Average 35000 EHP= 45,900 @ 30 knots EHP(hp) 30000 25000 20000 Good correlation between methods 15000 0 3 6 9 12 15 18 21 24 27 30 V(knots) Final Brief 06 Unclassified 39 Speed-Power Trends Power Requirement Validation Data compiled from Janes Speed-Power Trends 20.00 18.00 16.00 SHP/TON 14.00 SABR 12.00 Carriers Cruisers 10.00 Frigates 8.00 Auxilaries 6.00 4.00 2.00 0.00 0.20 0.25 0.30 0.35 0.40 0.45 0.50 Froude Number Final Brief 06 Unclassified 40 Propulsion AoA item weight MHD Water Jet Pod Technical Feasibility 0.15 1 0.15 4 0.6 4 0.6 0 3 0.45 4 0.6 Podded Propulsion: – Mature and proven technology – Compact – Well suited to all electric ship Weight & Volume 0.15 Efficiency Specific 0.15 1Propulsor 0.15 3 Selected: 0.45 3 0.45 Reliability 1 0.15 3 0.45 3 0.45 Motor0.15based on General Atomics Coverage superconducting Area low temperature 0.15 0 0 0 0 0 36 MW homopolar design. Life Cycle Cost 0.15 Manning 0.1 Total Final Brief 06 0 0 0 0 •Scaleable power output 0 0 0 0 0 0 •½1 the weight of a1.95 permanent 0.45 2.1 magnet motor Unclassified 41 EHP to SHP Velocity Resistance Delivered Power (Pd) per shaft KNs Lbs HP HP HP 5 13708 157 162 10 49587 1093 15 105135 3395 20 Shaft Power per Shaft Shaft Power TOTAL Open Water Efficiency RPM 324 0.716 19.2 1127 2254 0.743 37.3 3500 7000 0.761 54.9 Total of 55 MW = 30 knots 186249 8007 8254 16508 0.762 73.2 25 299834 16313 16818 33636 0.753 92.3 30 443046 29227 30131 60262 0.745 111.6 Kd-5-100 ln 33 Nozzle Propeller Matching Final Brief 06 – – – – – Blades: 5 Diameter: 16.79 ft P/D: 1.8 Area Ratio: 1.0 Open Water Efficiency: 0.747 Unclassified 42 Weights and Centers Final Brief 06 Unclassified 43 Weight Estimation • Parent Ship Method – Uses ratios between design characteristics and the known characteristics and component weights of a “parent” ship in order to generate a refined design weight estimation. – Parent Ship: LSD-49 • Similar design characteristics (B, T, LBP, Displacement, etc.) • Fundamentals of Naval Surface Ship Weight Estimating – Naval Engineers Journal, May 1983 – Author: Straubinger, Erwin K. Final Brief 06 Unclassified 44 Step 1: Initial Design Characteristics Excel file Final Brief 06 Unclassified 45 Step 2: Major Components Final Brief 06 Unclassified 46 Step 3: Group Calculations Design Estimated Weights Ratio Calculations Parent Ship Weights Final Brief 06 Unclassified 47 Step 4: Putting it All Together Total Estimated Design Weight Final Brief 06 Unclassified 48 Machinery Arrangements • Variables: – Total design estimated weight – Individual component weight – Location relative to center of buoyancy • Outputs: – VCG (above keel) – TCG (from centerline) – LCG (from LCB) **If minor component was not specifically placed within the design, its location was designated as the center of buoyancy Final Brief 06 Unclassified 49 Centers Calculations Summation of component moments = Group COG Component Moment = (Component Weight/Total Ship Weight) x Position Final Brief 06 Unclassified 50 Centers Results Excel file Group Summation Center of Gravity Final Brief 06 Unclassified 51 Hydrostatics & Intact Stability • Design meets stability criteria Curves of Form (with appendages) Coefficient 0.5 0.0 1.0 30.0 Pri smati c(Cp) Block(Cb) Mi dship(Cms) Water Plane(Cwp) Vol. ft^3 WS Area ft^2 Vert. Pri smatic (Cvp) Wet Surface (Cws) 25.0 d r a f t f t 20.0 15.0 Righting Arms vs. Hee l 10.0 0.0s Vol. ft^3 x 100000 WS Area ft^2 x 10000 Wet Surf ac e (Cws ) x 10 -1.0 -1.0 0.0 0.0 0.0 1.0 1.0 2.0 3.0 2.0 4.0 3.0 5.0 4.0 0.5 6.0 5.0 Righti ng Arm 7.0 8.0 Equi li brium 6.0 1.0 GMt 10.0p Heel angle (Degrees) 20.0p 30.0p 40.0p 50.0p 60.0p 5.0 20.0 A r m s i n 15.0 f t 10.0 5.0 0.0 Final Brief 06 Unclassified 52 600 Damaged Stability • Floodable Length – – 0.15 LBP, IAW DDS-079 3-compartment standard Floodable Length (ft) 500 400 Permeability: 0.95 Permeability: 0.85 300 200 3 center compartments flooded 100 0 0 5 10 15 20 25 30 35 40 3 forward compartments flooded Final Brief 06 Unclassified 53 Structural Outline Structure Primary Secondary Structural Element long'l girders, keelsons, transverse frames Design Material Advantage steel (HSLA80) stiffness (reduce deflection, whipping), ease of construction, low cost deckhouse, bulkheads, machinery foundations carbon composite 35-50% weight savings, low thermal conductivity, lower life-cycle costs, optimize complex geometries decks laser-welded corrugated core (LASCOR) 20-50% weight savings, increased stiffness, reduced assembly and fit-up costs, thermal and vibration insulation deckhouse plating carbon composite 35-50% weight savings, low thermal conductivity, lower life-cycle costs, integrated antennae structures hull plating Steel (HSLA80) stiffness (reduce deflection, whipping), ease of construction, low cost Tertiary Final Brief 06 Carderock composite-steel interface work Unclassified 54 Structure - Composite Applications Final Brief 06 Source: Carderock Division - Naval Surface Warfare Center NSWCCD-20-TR-2002/06 May 2002 HIGH-SPEED SEALIFT TECHNOLOGY DEVELOPMENT PLAN Unclassified 55 SOTS Array Placement Seakeeping and free surface flow predictions were combined to conduct array placement and statistically minimize wetness events. wav 1.27 1.13 0.99 0.85 0.71 0.57 0.43 0.29 0.15 0.01 -0.13 -0.26 -0.40 -0.54 -0.68 -200 Final Brief 06 -100 0 x 100 Z Y Unclassified 56 Wetness Events • Use 5 points and calculate the OI for each. – Choose the vertical clearance for each point such that: • Their individual Operability Indices' are about the same. • The Overall Operability Index is maximized. 120 100 Normalized OOI 80 1m 2m 60 3m 4m 40 20 0 1 2 3 4 5 Point Final Brief 06 Unclassified 57 Operating Envelope - SABR Sea State 4 Sea State 7 Final Brief 06 Sea State 5 Sea State 6 Unclassified 58 Where We Stand • • First iteration nearly complete Second iteration complete in some areas CAPACITIES TRIM & INTACT STABILITY Final Brief 06 Unclassified 59 Outline • • • • • • • • • • Systems Engineering Overview Power Plant Electrical Plant Hull and Mechanical EP Thermal Management Combat Systems H&M Manning Cost T Risk Management Building Bridges Final Brief 06 SE PP BB R $ CS M Unclassified 60 Thermal Management The Loads • Cooling Loads – Auxiliary systems (A/C, Reefers, etc.) – Radar (SPY and SOTS) – High Temperature Superconducting (HTS) Generators – Homo-Polar motor (Pod Propulsors) – Rail Gun Final Brief 06 Unclassified 61 Thermal Management The Plan • Auxiliaries – (2) York Marine Pak Reefer Units for refrigeration • Cooling Radars and interior compartments – (8) 200 Ton A/C Plants for Chill water • Three more plants than a CG47 to combat – Larger ship size – Increased ambient temperature as result of the SOTS • High Temp Cryogenics plants for the HTS generator • Low Temp Cryogenics plants for the Pod Propulsors Final Brief 06 Unclassified 62 Railgun Thermal Management • Cooling Loads and Solutions – Three pronged approach – Pre-cooling the rails with a lower Tinitial allows more time before Tcritical – Using a massive cold storage to cool down the chill water during the firing cycle. – Brute Force cooling: Using conventional chill water heat exchanger to cool the massive cold storage Brute Force Cooling Chill water Plant Final Brief 06 Massive Cold Source Rail Gun Pre-Cooling rails Unclassified 63 Outline • • • • • • • • • • Systems Engineering Overview Power Plant Electrical Plant Hull and Mechanical EP Thermal Management Combat Systems H&M Manning Cost T Risk Management Bridge Building Final Brief 06 SE PP BB R $ CS M Unclassified 64 Combat Systems • Sensor Fusion – Shipboard system data – S band and VHF/UHF radar data – Situational Awareness (real time and near real time) • Human Computer Interface – Data to information geospatially organized for quick reaction Final Brief 06 Unclassified 65 Combat Systems Air/Surface/Sub/Land Target Data Organic Sensor Organic Measurements Track Data Partially Fused Data Remote Sensor/Track Off Board Track Data Data Fully Fused Tactical Scene Displayed in a format that is best for the human Final Brief 06 Unclassified 66 Bridge and Amphitheater CIC Layout CIC: forward, console, and rear view Situational Awareness Pre-Process & Refine Measurement Data Fusion Correlate Tactical Data Correlate Operational Data Generate Integrated Tact. Picture Common Track Services Final Brief 06 Unclassified 67 Skin Of the Ship Radar • Notional Hull: 3,411 per ship side calculated to be 0.694m spacing • Data for DDG-1000: Final Brief 06 Unclassified 68 RCS Calculations • SABR RCS X-Band Emitter Max: abeam SHIP Tonnage (kT) Ave RCS (dBm) CG-47 9.6 46.9 DDG-51 8.3 45.9 SABR 15 54.8 Min: aft quarter • EA Capability Final Brief 06 Unclassified 69 Self Defense Systems • SABR is a standoff system and will have escorts in high risk environments • Hard Kill weapons – 2 Dual Quad mount NATO Sea Sparrow launchers • One Forward and One Aft • Can maintain Pk greater than 90% for up to 8 incoming missiles • Soft Kill and Countermeasures – Flares – Chaff – SLQ-32 V3 Final Brief 06 Unclassified 70 Outline • • • • • • • • • • Systems Engineering Overview Power Plant Electrical Plant Hull and Mechanical EP Thermal Management Combat Systems H&M Manning Cost T Risk Management Bridge Building Final Brief 06 SE PP BB R $ CS M Unclassified 71 Manning • Each crewmember belongs to a home network Daily Routine Watch Sections 1, 2, & 3 Day Schedules • Evolutions use the WQ&SB and the trump matrix to select crew members Scripted Evolution Schedule Final Brief 06 Unclassified 72 Total Crew Model Output Examples: Fatigue & Total Hours Breakdown Blue Gold Rotation 20 • Micro sleep begins ~ 9 • Micro sleep increases in duration & frequency as fatigue climbs 18 16 14 Exhausted Fatigue Level 12 10 OS1 OS2 OS3 OS4 8 6 4 2 Normal 0 -2 -4 0 2 4 6 8 10 Day Personal Needs Final Brief 06 Work Sleep Unclassified 73 Manning Results • Total Crew Size : Set to 130 based on DDG-1000 manning predictions. • The process for DDG-51 revealed that combination of micro and macro models can predict manning levels for small teams and subsequent total ship manning. • IMPRINT and Total Crew Model were micro and macro models implemented respectively Final Brief 06 Unclassified 74 Outline • • • • • • • • • • Systems Engineering Overview Power Plant Electrical Plant Hull and Mechanical EP Thermal Management Combat Systems H&M Manning Cost T Risk Management Building Bridges Final Brief 06 SE PP BB R $ CS M Unclassified 75 Cost Top Down • Tools – – – – CRS Report for Congress CBO (Transforming the Navy’s Surface Combatant Force) VAMOSC Data Base SEA-09 Report Final $ • • • Cost prediction is difficult on a project projected this far into the future with this many new advances. Due to the low confidence interval, a high degree of error needs to be accounted for. As time moves on and DDG 1000 is built and CG(X) progressed, the confidence level will increase. Final Brief 06 Confidence Level Bottom Up • Tools – – – – – Program level Request Component level Request Detailed weight-based CERs, Labor Costs, Specialized Equipment costs Unclassified 76 Top/Down Cost Estimate for BMD(X) Production CG(X) Estimated Cost ($Billion, 2006) BMD(X) Estimated Cost ($Billion, 2006) Detail Design 0.5 0.5 DD(X) estimate Basic Construction 0.8 0.8 Adjusted DD(X) estimate Phase Electronics 0.6 0.6 CHANGE Primary Basis Adjusted DD(X) estimate + skin of the ship radar Hull, Mechanical, and electrical systems 0.1 0.9 Ordnance 0.6 0.8 Adjusted DD(X) estimate + rail gun Other 0.2 0.2 DD(X) estimate Subtotal 2.3 3.3 Change orders 0.4 0.5 Total Production Cost 2.7 3.8 TOTAL COST 3.2 4.3 Final Brief 06 DD(X) estimate + nuclear propulsion Percentage of Production Cost Unclassified 77 Characteristic/Follow-Ship Procurement/O&S Comparison Ship Class Type BMD(X) Ballistic Defense Ship Displacement (tons) 15,000 Crew Size O&S (FY06 $M) Armament Missions 130 Next generation radar system, 4 railguns, Long range missile defense and land attack 4,300 38.0 Long-range air and missile defense, land attack 3,200 48.0 Land attack, ASW *2,700 40.5 1,800 31.2 2,000 38.9 CG(X) GuidedMissile cruiser 16,000 or more N.A Next-generation air and missile defense combat system, 200VLS cells, two helicopters, possible other systems DD(X) GeneralPurpose Destroyer 16,000 130 2 Helo, 2 155-mm AGS, 128 VLS DDG-51 (II) GuidedMissile Destroyer 9,200 340 AEGIS, 2 Helo, 1 5-inch, 96 VLS CG-52 GuidedMissile Cruiser 9,500 410 AEGIS, 2 Helo, 2 5-inch, 122 VLS Final Brief 06 Follow ship procurement cost (FY06 $M) Long-range air and missile defense, land attack, openocean ASW Long-range air and missile defense, land attack, openocean ASW Unclassified 78 Cost $5.2Billion $4.3B Confidence Level $3.4Billion The high and low is based on +/- 20% on $4.3Billion Final Brief 06 Unclassified 79 Outline • • • • • • • • • • Systems Engineering Overview Power Plant Electrical Plant Hull and Mechanical EP Thermal Management Combat Systems H&M Manning Cost T Risk Management Building Bridges Final Brief 06 SE PP BB R $ CS M Unclassified 80 Five Element Risk Management Process Analyze & Prioritize Risks Identify Risks Plan & Implement Risk Handling Approach Report & Control Risks Monitor Risks Risk management is an ongoing, iterative process Final Brief 06 Unclassified 81 Risk Relationships Technical Risk Compressed Schedules Limited Funds Threat Change Programmatic Risk Imposed Budgets Demand Schedules Schedule Risk Cost Risk Schedule Slips Final Brief 06 Unclassified 82 Risk Results Final Brief 06 Unclassified 83 Outline • • • • • • • • • • Systems Engineering Overview Power Plant Electrical Plant Hull and Mechanical EP Thermal Management Combat Systems H&M Manning Cost T Risk Management Building Bridges Final Brief 06 SE PP BB R $ CS M Unclassified 84 Building Bridges ARL Final Brief 06 Unclassified 85 Review • • • • • • • • • • Systems Engineering Overview Power Plant Electrical Plant Hull and Mechanical EP Thermal Management Combat Systems H&M Manning Cost T Risk Management Building Bridges Final Brief 06 SE PP BB R $ CS M Unclassified 86 Questions? Final Brief 06 Unclassified 87