Your our Challenge solutions

advertisement

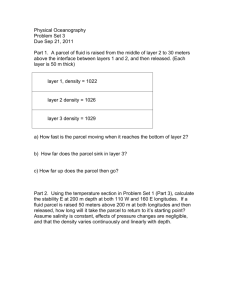

Your Challenge our solutions Parcel & Postal Our value “ Our sorting process had to continue without interruption while the new systems were installed - a task that was like performing open-heart surgery while the patient was awake “ UPS Louisville Fast-changing market demands mean new opportunities in parcel & postal handling. But challenges like labour costs, pressure on space and efficient peak handling remain. It’s a constant search for lower operating costs, more productivity and – most of all – ever higher service levels. Working together Meeting your customers’ changing and intensifying demands has top priority. For example increasing unit volumes and variety, tighter sorting windows, higher delivery frequencies and shorter lead times. At the same time, pressures are increasing: you need to do more in a shorter time, at less cost and in the same space as before. Based on our in-depth understanding of parcel & postal business processes, we provide competitive automated solutions for hubs and depots of all sizes. These enable you to improve your service level at lower operating costs. With our flexible solutions, you’re ready to take advantage of the changing market demands. Our systems and services focus on improving your processes and increasing your performance – today, tomorrow and right through the life cycle. We work closely together with you, from initial business process analysis through to total life-cycle support. To do that, we have in-depth industry knowledge and can offer a wide range of solutions. We posses all the required capabilities – from system design through supply chain management and manufacturing, to information and communication technology, system integration, project management and customer services. Parcel & Postal UNDERSTANDING YOUR business process Our company “ The company implements material handling systems of all sizes, ranging from many local sorting depots, airports and distribution centres to the world’s largest facilities. The company ranks among the top 5 worldwide in its field “ Magazine Modern Materials Handling Parcel & Postal YOUR CHALLENGE, OUR SOLUTIONS Vanderlande Industries is a leader in automated parcel & postal handling solutions, with a track record of over 500 satisfied customers. We are also among the leading suppliers of airport baggage handling systems and integrated logistics systems for warehouses and distribution centres. Global player with local presence We have a proven capability in delivering reliable solutions in teamwork with our customers, as a global player with extensive worldwide experience in the parcel & postal industry. Our headquarters are in Veghel, the Netherlands, and we also have offices in Belgium, Germany, the UK, Italy, France, Spain, USA, South Africa, Russia, India, Canada, Argentina, Australia, the UAE and China. Our local Customer Centres handle all key business functions and maintain direct contact with customers. What drives us is exceeding customers’ expectations, reflected by our core value: ‘building reputation with customers’. Excellent product and software portfolio As well as a complete range of state-of-the-art sorting, transport and loading/ unloading equipment, our systems include modular, scalable software solutions. These provide valuable real-time information on system status, workload and performance, and enable operation to be constantly optimised. At the same time they provide management with the decision support intelligence needed for scheduling, planning and forecasting. CUSTOMER CENTERS AGENTS Our company Putting people first A safe and healthy working environment is paramount in parcel & postal sorting centres. We take this responsibility seriously, and as an industry leader we set ourselves high standards. A key area of employee well being in which Vanderlande leads the industry is ergonomics. We invest significant time, resources and research in designing our systems so they best match the movements and cognitive abilities of individual users. For example, our ergonomic telescopic extendable conveyors increase productivity by minimising the need for manual carrying of products. The drop-off and take-away points are placed directly at the operator’s side, accessible on-demand by simple joystick movements. A number of safety features are incorporated allowing safe and easy operation. Together this creates a fatigue-free working environment for operators, with significantly reduced need to lift heavy products. Parcel & Postal Making a positive impact Optimising energy efficiency is essential. This not only lowers operating costs, it also reduces your carbon footprint. That’s why supporting our customers in improving the energy efficiency of their logistics processes is one of our top priorities. Just one example is our Energy Scan programme, which has proved to achieve energy savings of more than 50%: the first step towards implementing a ‘green hub’. Delivering the highest-quality solutions is our top priority. This extends right through to the materials we use. Our innovation strategy is based on the closed-cycle ‘Cradle to Cradle®’ principles. That means we assess materials not only on their tangible properties, but also by their effects on people and the environment and their capacity for recycling. This approach has already resulted in unique products that save energy and maximise sustainability. For example the BLUEVEYOR next-generation conveyor system that takes a significant step in reducing environmental impact. And the CROSSORTER for flexible sorting of a wide range of products with maximum eco effectiveness. Your challenge “ This highly advanced and modern sorting facility will mean a big quality increase for the Polish express parcel industry “ DPD Poland Vanderlande Industries is dedicated to improving your business processes and your competitive position. We do that with effective, reliable automated material handling systems and supporting services. Our focus is on increasing your logistics performance – today, tomorrow and right through the life-cycle. Increase your service level Meeting your customers’ service level demands is an increasingly tough challenge. For example shorter order lead times, later cut-off times, smaller orders and greater product diversity. Plus the need for maximum delivery reliability with zero-fault performance. While at the same time you need to constantly reduce costs and serve widely varying customers, making your operations increasingly complex. Automating your hubs and depots, based on a thorough understanding of your logistics processes, provides numerous opportunities to save cost and increase your service level. In addition, automation plays a vital role in addressing today’s business challenges, taking advantage of new business opportunities and strengthening your position as a trusted delivery partner. Benefit from growth in e-commerce Fast-growing e-commerce business models mean big changes for parcel & postal operators. Rapid order fulfilment, shorter process timeframes, higher delivery frequencies, even more pressure on cost per item handled – all demand maximum flexibility and logistics performance. Our effective automated systems and software are proven in state-of-the-art parcel & postal hubs around the world. Parcel & Postal IMPROVING YOUR COMPETITIVE POSITION Your challenge Avoiding jams for the highest system availability Ensuring the highest possible system availability is a key challenge in automated hubs and depots. Our innovative PARCELCHECK application uses advanced vision and image-processing technology for in-line parcel characterisation. This allows the conveyability of products to be determined, and can also be used to register the condition of incoming goods at the point of entry. Avoiding jams downstream in the process is a key benefit of this technology. This product identification and detection results in improved overall system performance with higher availability and throughput. And unlike a human operator, it performs consistently and tirelessly all the time. Lowest handling costs per product Pressure on operating costs makes it essential to maximise economy and efficiency. Automating logistics handling makes a big contribution. Not only by reducing manual labour and increasing productivity, but also through more efficient space utilisation and lower energy consumption, all of which have a direct impact on costs and profitability. Parcel & Postal Optimise space utilization Space is scarce and costly. With room for physical expansion frequently limited, it’s necessary to handle higher product volumes in the same facilities as before. Compact and highly productive automated systems are the answer. Our solutions will improve space utilisation in your facility by up to 60%, and can multiply throughput per m2 by as much as three times. Ready for future growth / scalability In today’s market conditions it’s important to prepare for future growth and new business demands. With a system concept that’s productive and cost-effective today, but easily scalable to handle increasing product volumes economically. Our system solutions are designed to be ready for the future, so they can grow seamlessly together with your business needs. Our solutions “ Vanderlande Industries showed a good understanding of our processes and they were capable of translating our requirements into an optimum sorting solution “ TNT Through in-depth understanding of parcel & postal logistics and the underlying business processes, we can provide turnkey automated solutions for hubs and depots of all sizes. Our flexible solutions maximise efficiency, enable continuous process improvement and can easily be adapted to changing market demands. Sortation systems One of the most important challenges is reliable, accurate sorting within the required timeframe and to the right outgoing dock, without the need for manual intervention. Vanderlande Industries offers the full range of sorter technologies. The system that best suits your process depends on the sizes, weights and types of products you handle, as well as on the required capacity, the available space and your building shape. As well as conventional line sorters, we have developed a new generation of loop sorters offering higher capacities with reduced labour requirements. Our sorters can reliably, safely and gentle handle products as diverse as bags, boxes of wine and unstable packages like flower boxes, with capacities as high as 10,000 products per hour or more. Unloading and loading devices A productive automated parcel & postal handling process starts with the ability to load and unload a constant flow of vehicles quickly and smoothly. A wide range of configurations can be used for this purpose, with the choice depending mainly on the types of vehicles. For example for loose-loaded parcels we offer a range of telescopic extendables with belt or roller conveyors. These offer fast loading and unloading with ergonomic working conditions. Extension and retraction are motor driven, load positioning is joystick-controlled, and manual carrying of heavy loads is eliminated. Parcel & Postal MEETING YOUR SYSTEM REQUIREMENTS Our solutions Flexible software solutions for full control Tighter schedules, higher volumes and increasing customer demands make IT an essential part of your logistics process. Vanderlande Industries’ VISION software suite offers a flexible, modular solution for end-to-end planning and control. VISION is a highly reliable, modular and scalable software platform that supports you in optimising your logistics process every day, or even better every hour VISION provides an operational performance dashboard that visualises your daily planning, provides a real-time process overview, and allows remote access to your total automated system. VISION integrates seamlessly with your existing systems and low-level controls. The actual system configuration and dynamics are taken into account to make smart, real-time decisions in sending products to the required physical locations. Parcel & Postal Integrated access to business-critical information VISION provides integrated access to business-critical information. Extensive management information and reporting functions provide a constant indication of system status and workflow progress. Real-time performance information can be used as a tool for process improvement and fine-tuning. The dashboard display showing information on system status can be accessed conveniently online from any PC or mobile device. Your performance Exceeding your customers’ expectations with an effective parcel & postal handling process: that’s the goal of our supporting services. We provide a worldwide network of field service engineering, full remote IT support facilities and a global spare parts supply chain. Day-to-day support Our goal is to keep your logistics process running smoothly and efficiently. We offer maintenance support from periodical inspections and spare parts supply to full 24/7 on-site support by Vanderlande staff. Together with you, we can define a package of maintenance and support services that will most effectively meet your needs. continuous optimisation Our services keep your automated logistics system working optimally, even as your operational requirements change over time. Our supporting services can be extended by performance analysis, tooling and advice. These allow continuous improvement of your system and logistics process performance, and support you in responding to changing business conditions. Parcel & Postal Services to optimise your operations our Track record Vanderlande Industries is among the world’s leading suppliers of automated logistics solutions, with a proven track record of automating over 500 hubs and depots in recent years. We develop solutions in teamwork with our customers. This forms the basis for our solid reputation. references Parcel & Postal LEADING BY EXAMPLE A_DOC167931EN www.vanderlande.com This information is subject to change without notice and should not be construed as a commitment on the part of Vanderlande Industries.