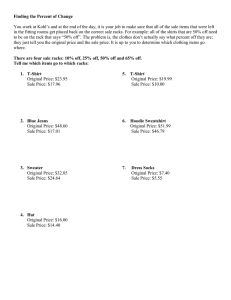

DRIVE-IN / DRIVE THRU RACK

advertisement

DRIVE-IN / DRIVE THRU RACK SpaceRak Drive-in / Drive-thru racks reduce the amount of conventional traffic aisles, permitting maximum use of space for high density, floor-to-ceiling palletized storage. DRIVE IN RACKS Drive In Racks allow vehicles to enter the storage area for pallet placement in a backto-front arrangement, and require the operator to back-out of the rack after pallet placement. Drive In Racks are ideally suited for “FIRST-IN / LAST-OUT” inventory management. Drive In systems can also be designed as "double entry systems" in a back to back arrangement. Double entry systems allow for greater density and allow for entry on both sides of the system. DRIVE THRU RACKS: Drive Thru Racks have two access aisle for loading and retrieval. Lift Trucks can pass through the rack bay, placing loads on supporting rails from one side, and exit in the same direction. Trucks can also enter the rack bay fro the opposite side to remove loads. Drive-Thru Racks are well suited for “FIRST-IN / FIRST-OUT” inventory movement. Designed for High Density Storage utilizing the maximum warehouse storage cube while keeping aisle space to a minimum. Drive In / Drive Thru racks are designed using Structural Steel. PHYSICAL FEATURES • Drive-In available in Single or Double Entry design • System is available in Structural Steel • Load Rails are top-mounted to Arms • Arms are Tapered Structural Angle for clearance & strength • Entry Frames enhanced with Off-Set or Kant-Back Style Both Drive-In and Drive-Thru systems offer the advantages of high-density storage and lower costs. MODEL OPTIONS Frame Types: • Structural Channel Depth Styles • Drive-In Single Entry & Double Entry • Recommended up to 10 Deep, per side • Drive-Thru – recommended up to 10 deep In-Bay Lift Truck Guidance: • Floor-Mount Guide Angle, Rack Mounted Rub Rails Load Rails: • Structural Angle Rail – 3/16" & 3/4" • Column Section – 14ga & 13ga Top Tie Beams & Rail Support Beams: • Top-Ties for systems greater than 3 Deep • Rail Support Beams for rear position of all Drive-In systems Horizontal & Vertical X-Bracing • Required & supplied as needed per design requirements and local codes HARDWARE INCLUDED Simple installation to floor. FOR MORE INFORMATION ON OUR PRODUCTS AND SERVICES VISIT WWW.SPACERAK.COM www.SpaceRAK.com • (800) 336-3926 2420 Wills Street Marysville, MI 48040 P: 810-364-7421 F: 810-364-5610 custsvc@spacerak.net spacerak.com 213 Kelly Street Lodi, CA 95240 P: 209-367-4444 F: 209-367-4445 custsvc@spacerak.net spacerak.com Saf-T-Products 355 Industrial Drive Harrison, OH 45030 P: 513-367-0080 F: 513-367-0081 Toll Free: 800-333-0080 custsvc@spacerak.net spacerak.com SPACERAK STORAGE SOLUTIONS. An industry leader working with material handling distributors for more than 50 years, SpaceRAK puts more storage solutions within your reach. By operating manufacturing facilities in Michigan, Ohio and California, along with distribution points in Pennsylvania, Ohio and Illinois, we deliver your solutions, when you need them, at the right value. For high-quality selective racks, drive-in racks, pushback systems, and cantilever racks, look no further than SpaceRAK. Learn more by visiting us at www.SpaceRAK.com. CANTILEVER RACKS DRIVE-IN / DRIVE-THRU RACKS SELECTIVE RACKS SAF-T-RAILS ENGINEERED SYSTEMS 2420 Wills Marysville, MI 48040 • (800) 336-3926 • (810) 364-7421 • Fax (810) 364-5610 • www.spacerak.net