Synthesis and Magnetic Properties of Copper Borates in Preparation for... Doping Studies S. M. Madison

advertisement

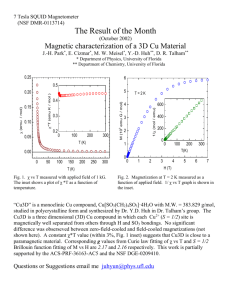

Synthesis and Magnetic Properties of Copper Borates in Preparation for Electrochemical Doping Studies S. M. Madison*, D. C. Johnston, and J. M. Hill Ames Laboratory and the Department of Physics and Astronomy Iowa State University, Ames, IA 50011 I. INTRODUCTION This research project was part of Iowa State University’s 2002 Research Experience for Undergraduates (REU) program. The specific objective of the research project was to synthesize and characterize insulating copper oxide materials. First, a single phase sample of the compound SrCu2(BO3)2 was made. Second, a powder x-ray diffraction pattern was used to correctly identify and characterize the structure of the sample. Third, a superconducting quantum interference device (SQUID) magnetometer was used to measure the magnetic moment of the sample as a function of temperature and field. Fourth, accurate analyses of the SQUID results were performed. Fifth, the results of the research project were presented in the form of this paper and a poster session. The overall goal of this research project was to create single phase samples of SrCu2(BO3)2, β-Sr2Cu(BO3)2, and Sr2CuO3, which are insulators. These samples would then be evaluated further for the possibilities of different doping techniques, including hole-doping and electron-doping,1,2 to develop a material that is a metal with potentially interesting and important physical properties. * Permanent Address: Department of Physics, Fort Hays State University, Hays, Kansas 67601 1 Fig. 1: (a) Lattice structure of the Cu2+ spins of SrCu2(BO3)2. The nearest-neighbor bonds are expressed by solid lines and the next-nearest-neighbor bonds by broken lines. (b) Elementary unit for the interaction between a pair of nearest-neighbor bonds (taken from Ref. 3). The compound SrCu2(BO3)2 was of particular interest for this research project because it is a physical realization of a model which has been known to scientists in low dimensional magnetism for years. The crystal structure is made up of alternating planes of Sr2+ ions and Cu2(BO3)2 planes containing the Cu2+ dimers.4 Fig. 1(a) shows a layer of orthogonal arranged 2 dimers and Fig. 1(b)3 illustrates the geometrically frustrated antiferromagnetic interaction between Cu2+ ions. The nearest-neighbor bond length is 2.905 Å and has an intradimer exchange interaction of J/kB = 100 K,3,5,6 for an assumed Heisenberg interaction Hamiltonian r r H = J ∑ Si ⋅ S j < ij > . (1) Here, each pair of interacting spins occur once in the sum, and Jif > 0 (<0) corresponds to r r S S antiferromagnetic (ferromagnetic) interactions between spins i and j . The next-nearest- neighbor bond length is 5.132 Å and its interdimer exchange interaction is J′/kB = 68 K.3,5,6 The dimer sublattice in SrCu2(BO3)2 forms a two-dimensional, spin-½, spin gap system with an exactly solvable ground state.3 Miyahara and Ueda, in 1998,5 showed that the solution is equivalent to the Shastry-Sutherland model,7 proposed in 1981. SrCu2(BO3)2 is an insulator, but the properties of doped samples are of prime interest, given the similarities between SrCu2(BO3)2 and the high-Tc cuprates. Can SrCu2(BO3)2 be made metallic through doping, and if so, will it exhibit superconductivity? To our knowledge, there exists only one report of successfully doping SrCu2(BO3)2 in the literature,1,2 and the physical properties of the doped samples were not well characterized. In this paper, we discuss the synthesis and magnetic properties of undoped SrCu2(BO3)2 samples, which were made as precursors for future doping studies. The XRD pattern produced for the first sample of SrCu2(BO3)2 consisted of traces of the compound β-Sr2Cu(BO3)2. Sr2Cu(BO3)2 undergoes a transition from a monoclinic lowtemperature α-form to an orthorhombic high-temperature β-form at approximately 800 °C.8 The β-phase was of more interest due to the presence of isolated Cu2+ dimers in the unit cell, as shown in Fig. 2. It was therefore synthesized in pure form and the magnetic properties were characterized. 3 Fig. 2: Crystal structure of β-Sr2Cu(BO3)2. Cu atoms are blue, B atoms are yellow, O atoms are black, and Sr atoms are red. The Cu-Cu dimer bonds are solid lines. Finally, the orthorhombic compound Sr2CuO3 is an intermediate material in the synthesis of β-Sr2Cu(BO3)2, and is interesting in its own right. This material contains chains of Cu2+ ions and has been well-characterized previously in the literature. A brief review of the physical properties of Sr2CuO3 can be found in Ref. 9 (and references therein). Synthesis details are given in Section II and magnetization measurements are presented 4 and discussed in Section III. X-ray powder diffraction (XRD) patterns were collected on a Rigaku x-ray diffractometer using Cu Kα radiation. Magnetic susceptibility and magnetization measurements below 300 K were collected for SrCu2(BO3)2 samples SMM7.41 and SMM8.43, Sr2CuO3 sample SMM6.33, and β-Sr2Cu(BO3)2 sample SMM6.33 using a Quantum Design SQUID magnetometer. A gelcap and straw holder with known background signals were used. II. EXPERIMENTAL DETAILS SrCu2(BO3)2 Seven samples of SrCu2(BO3)2 were synthesized for analysis. Because of the complications caused with powdered B2O3, several different procedures were attempted in order to find the most ideal and reliable synthesis method. Only sample SMM1.2 was made with powdered B2O3 (Alfa Catalog Chemicals, 99.99% pure (metals basis)). The six additional samples of SrCu2(BO3)2 were made with anhydrous B2O3 (Alfa Aesar, 99.9995%, 200 ppm water). In addition, CuO (Alfa Aesar, 99.995%) and SrCO3 (Aithaca Chemical Corp., 99.995%) were used for all samples. The samples are identified by the initials of the author, followed by the consecutive numbering of samples and the page number in the research notebook in which they were begun (SMMx.xx). A variety of side experiments were performed due to complications arising from the water content of the powdered B2O3. The first sample of SrCu2(BO3)2 (SMM1.2) lost a significant amount of weight beyond the calculated expected weight loss due to the release of CO2. This extra weight loss was assumed to be water loss and doubts began forming about the exact composition of that B2O3. The XRD pattern of this B2O3 did not match the accepted pattern for B2O3,10,11 but rather that for B(OH)3.12 5 Two large samples of the B2O3 were “dried” in air at 200 °C and 110 °C, but in both cases the samples gained weight and partially melted. Several samples of B2O3 were also analyzed in a Perkin-Elmer thermogravimetric analyzer (TGA) for water content. The TGA records the weight change of a sample with respect to temperature and time. The first sequence was run in air for 5 hours with a maximum temperature of 400 °C; the melting point of B2O3 is 460 °C. Although the B2O3 sample lost weight, it melted, complicating the results. The total mass loss was 16.15% of the total initial sample mass, which is close to the 20.87% extra mass loss experienced by sample SMM1.2. The melting point of B(OH)3 is 170 °C, much lower than that for B2O3. Assuming that B(OH)3 is the compound that has formed in place of the B2O3, the following reaction can be written: B(OH)3 → HBO2 +H2O. The melting point of HBO2 is 236 °C. A second sample of B2O3 was heated in air in the TGA to 200 °C to prevent the sample from melting. The total mass loss was 14.23% of the total initial sample mass, which is fairly consistent with the previous run at 400 °C. The third TGA analysis of B2O3 was run in flowing oxygen with a maximum temperature of 200 °C. The total mass loss was only 11.94% of the total initial sample mass. Although this mass loss is less than those previously recorded, it is still acceptable because the exact homogeneity of the B2O3 in the original bottle is not known. It is within reason to state that the water content of the powdered B2O3 ranges between 12 - 16 wt. %. Therefore, glassy, anhydrous B2O3 was specially ordered and used for the remaining sample preparations. Sample SMM1.2 was synthesized by heating stoichiometric quantities of the powdered B2O3, CuO, and SrCO3 at 850 °C in air for 4 days with one intermediate grinding. (SrCu2(BO3)2 decomposes at 970 °C.) Figure 3 shows the XRD pattern, which matches that 6 obtained from the JCPDS database (#85-2420 tetragonal SrCu2(BO3)2)4 with very few extra peaks. The extra peaks are CuO and monoclinic β-Sr2Cu(BO3)2. SMM1.2 was heated at 850 °C for 2 more days and then analyzed by powder XRD again. The x-ray pattern showed the same impurity peaks, but at a lower intensity. SMM1.2 was then heated at 900 °C for 1 day and another XRD pattern was collected. The ratio of impurity peaks to Sr2Cu(BO3)2 peaks decreased again, signifying the approach to a single phase sample. 3500 SrCu (BO ) 2 3000 SMM1.2 CuO β-Sr2Cu(BO3)2 3 2 I (Counts/s) 2500 2000 1500 1000 500 0 0 20 40 60 80 100 o 2θ ( ) Fig. 3: Cu Kα x-ray powder diffraction pattern of SrCu2(BO3)2, sample SMM1.2. The solid curve is intensity I versus diffraction angle 2θ. Impurity CuO (•) and β-Sr2Cu(BO3)2 (o) reflections are indicated. Sample SMM2.16 was synthesized by heating a stoichiometric mixture of B2O3, CuO, and SrCO3 at 850 °C for 2 days as a powder and then at 900 °C for 1 day as a pellet. The expected mass loss due to CO2 release was exceeded by ~5%. The XRD pattern, shown in Fig. 7 4, is primarily SrCu2(BO3)2 with some CuO and other unidentifiable phases. The presence of extra CuO starting material may be due to the fact that some of the B2O3 used was lost because of difficulties in grinding it and its propensity to shatter. SMM2.16 was repressed into a pellet, and heated at 900 °C for 1 day. A second XRD pattern showed little to no differences from the first. 2500 I (Counts/s) 2000 SrCu2(BO3)2 CuO SMM2.16 1500 1000 500 0 0 20 40 60 80 100 o 2θ ( ) Fig. 4: Cu Kα x-ray powder diffraction pattern of SrCu2(BO3)2, sample SMM2.16. The solid curve is intensity I versus diffraction angle 2θ. Impurity CuO (•) reflections are indicated. For sample SMM3.18, a pellet was pressed with the correct stoichiometric quantities of CuO and SrCO3, and a piece of the crystalline B2O3 was placed on top of the pellet. This procedure was used so that no B2O3 would be lost while trying to grind it. This sample was heated at 500 °C for 2 hours, after which it was observed that the B2O3 had melted on top of the pellet. SMM3.18 was then heated at 500 °C for 1 day, and then at 600 °C for 6 hours. At this 8 3500 SrCu (BO ) 2 3000 SMM3.18 CuO 3 2 Unknown I (Counts/s) 2500 2000 1500 1000 500 0 0 20 40 60 80 100 2θ (o) Fig. 5: Cu Kα x-ray powder diffraction pattern of SrCu2(BO3)2, sample SMM3.18. The solid curve is intensity I versus diffraction angle 2θ. Impurity CuO (•) and unknown (o) reflections are indicated. point, it appeared as if the surface tension of the B2O3 was breaking up because the melted B2O3 was more spread out, as opposed to a single bead sitting on top of the pellet. Also, the B2O3 appeared to have tiny bubbles in it, which could be caused by the release of CO2 gas from the CuO/SrCO3 pellet. The mass loss was 1.5% of the initial sample mass; the expected mass loss due to CO2 release was 0.034 g, or 12.57% of the total initial sample mass. SMM3.18 was heated at 600 °C for another day, but no significant change in appearance or mass was observed. SMM3.18 was then heated at 700 °C for 7 hours. The mass loss at this point was 33.24% of the expected mass loss. SMM3.18 was heated at 700 °C for 1 day; there were no significant changes. SMM3.18 was heated at 750 °C for 7 hours. The CuO/SrCO3 pellet was a greenish color, with a few bluish spots. The total mass loss at this point was 57.65% of the expected mass 9 loss. SMM3.18 was then heated at 800 °C for 3 days. The B2O3 finally reacted with the pellet and the entire pellet was green. The total mass loss had exceed the expected mass loss by ~12%. We believe the excess mass loss may be due to the evaporation of B2O3. SMM3.18 was ground up, pressed into a pellet, and heated at 850 °C for 3 days. The bluish gray pellet continued to lose weight. The XRD pattern shown in Fig. 5 is quite clean, with only a few lines of the starting material CuO and other unidentifiable peaks. SMM3.18 was then heated at 900 °C for 4 days with one intermediate grinding and pelletizing. The XRD pattern did not change. For sample SMM 4.29, CuO and SrCO3 were pre-reacted in pellet form at 900 °C for 5 days, immediately followed by 950 °C for 1 day. The total mass loss was ~86% of the expected mass loss. The hope was that by pre-reacting the CuO and SrCO3, all of the CO2 would be released before the B2O3 was added, thus facilitating the reaction of B2O3. SMM4.29 was then heated at 1050 °C in the high temperature tube furnace for 1 day, but the sample melted and formed a shiny black compound. The SrO-CuO phase diagram, shown in Fig. 6, shows that at 66.67 Mol % CuO, a phase transition takes place at temperatures above 960 °C to SrCuO2 + liquid.13 Sample SMM5.30 was prepared similarly to SMM3.18 and heated at 750 °C for 3 days. The B2O3 melted and was on top of the pellet as well as around the bottom of the crucible. The reason the B2O3 didn’t stay on top of the pellet may have been because a larger piece was used and the surface tension was not strong enough to hold that big of a piece together. The pellet appeared green, possibly because of a reaction with the B2O3. The total mass loss was ~7% of the expected mass loss. SMM5.30 was heated at 750 °C for 1 more day; there were no significant changes in either appearance or mass. SMM5.30 was then heated at 800 °C for 1 day; there were no significant changes in appearance, but the total mass loss was now ~12% of the 10 expected mass loss. SMM5.30 was heated at 850 °C for 1 day; there were no significant changes. SMM5.30 was heated at 950 °C for 1 day. The sample melted and was black and dark green in color. No additional analysis of the sample was possible. Fig. 6: SrO-CuO phase diagram (taken from Ref. 13). Sample SMM7.41 was made by pre-reacting CuO and SrCO3. Throughout the heating process, the sample was reground so that the homogeneity could be maintained, 11 hopefully helping the CO2 to be released more rapidly. A 10% excess of CuO and SrCO3 was added to the stoichiometric starting mixture to compensate for any that might be lost in the grinding and pelletizing process. A pellet was heated at 900 °C for 3 days and cooled in He. The gray pellet had lost ~80% of the expected mass loss from CO2 release. SMM7.41 was then heated at 950 °C for 7 days with intermediate grindings and weighings. At this point, the pellet still had to lose 44 mg of CO2 before the B2O3 could be added. The sample was ground and reheated at 950 °C for 2 days in powder form. The sample had 26 mg of CO2 remaining to release. At this point, it was determined that the B2O3 could be added to the reground powder. SMM7.41 was then heated at 500 °C for 1 day. The B2O3 melted and was situated on the middle of the powder in a pool of liquid. It was heated at 750 °C for 1 day. The B2O3 was no longer in liquid form. It had reacted with the powder, which was a greenish color. This mixture was ground, pelletized, and heated at 900 °C for 3 days. The blue pellet was reground, repressed, and reheated at 900 °C for 1 more day. SMM8.43 was prepared by pre-reacting CuO and SrCO3 in powder form, as opposed to the pellet form used in SMM7.41. This procedure would help to determine the most efficient way of releasing the CO2 before the addition of B2O3. Stoichiometric quantities of the CuO and SrCO3 were heated, uncovered, at 900 °C for 4 days with three intermediate grindings. At this stage, there was still 15 mg of CO2 left to be released, however the B2O3 was added to the powder. SMM8.43 was then heated at 500 °C for 3 days. The black powder had liquid B2O3 on top of it. This mixture was ground, but it was determined that the B2O3 was too hard to grind effectively. Therefore, the powder was mixed with the smaller pieces of B2O3 that could not be ground. This mixture of SMM8.43 was heated at 600 °C for 1 day, ground into a homogeneous mixture, and heated at 700 °C for 1 day. There was some mass loss experienced, which was 12 assumed to be B2O3 loss. The black powder was ground, and it was observed that a small spot on the bottom had begun to turn a bluish color. SMM8.43 was heated at 800 °C for 1 day with no significant changes and then heated at 900 °C for 1 day. The blue powder was almost completely uniform in color. SMM8.43 was then reheated at 900 °C for 3 days. The blue pellet was ground and a portion mixed with a small amount of Si for the x-ray. The XRD pattern, shown in Fig. 7, is single phase except for a single CuO peak. This excess CuO may be attributed to the additional mass loss, possibly B2O3, experienced by the sample. It shows the reported tetragonal structure with lattice parameters a = 8.9872(8) Å and c = 6.6475(9) Å, which are consistent with literature values.4 Not enough Si was mixed with the sample to be able to clearly identify its peaks, so the lattice parameters were determined by fitting to a constant angle offset. 10000 SrCu (BO ) 2 I (Counts/s) 8000 CuO Si 3 2 SMM8.43 6000 4000 2000 0 0 20 40 60 80 100 2θ (o) Fig. 7: Cu Kα x-ray powder diffraction pattern of SrCu2(BO3)2, sample SMM8.43. The solid curve is intensity I versus diffraction angle 2θ. The space group is tetragonal I42m (#121) with a = 8.9872(8) Å and c = 6.6475(9) A. Impurity CuO (•) and Si (o) reflections are indicated. 13 A test was performed to determine if the compound SrCu2(BO3)2 would react with water. A piece of sample SMM8.43 was placed in a vial of deionized water. No reactions were observed immediately. However, after several days the lid popped off, due to the release of a gas, and there was a white substance floating in the water, indicating a chemical reaction had occurred. In electrochemical cells, samples are not exposed to the solution for long periods of time, so aqueous electrochemical doping may still be possible with SrCu2(BO3)2. Sr2CuO3 3500 Sr CuO 2 3 3000 SMM6.33 I (Counts/s) 2500 2000 1500 1000 500 0 0 20 40 60 80 100 o 2θ ( ) Fig. 8: Cu Kα x-ray powder diffraction pattern of Sr2CuO3, sample SMM6.33. The solid curve is intensity I versus diffraction angle 2θ. The space group is orthorhombic Immm (#71) with a = 3.9114(9) Å, b = 3.4984(7) Å, and c = 12.701(4) Å. The synthesis procedure for making β-Sr2Cu(BO3)2 included making an initial sample of Sr2CuO3. Stoichiometric quantities of SrCO3 and CuO were heated in powder form at 900 °C for 14 1 day. The sample was cooled in a He atmosphere because Sr2CuO3 reacts very quickly with air.9 The brown powder lost all of the expected mass loss from CO2 release. SMM6.33 was then annealed at 950 °C for 1 day. The sample is single phase according to the XRD pattern shown in Fig. 8, and has the reported orthorhombic structure with lattice parameters a = 3.9114(9) Å, b = 3.4984(7) Å, and c = 12.701(4) Å, in good agreement with literature values.14 β-Sr2Cu(BO3)2 SMM6.33 was initially the compound Sr2CuO3. Once the CO2 gas was released, which was determined by the mass loss, a stoichiometric piece of B2O3 was added to the pellet of Sr2CuO3, and the sample was heated at 500 °C for 1 day. The B2O3 melted and stayed on top of the dark pellet. SMM6.33 was heated at 550 °C for 1 day; there was very little change in the appearance. SMM6.33 was heated at 650 °C for 2 days; there was no change in the appearance of the sample. SMM6.33 was heated at 750 °C for 3 days. The pellet appeared to have spots on it that may be reactions with the B2O3. SMM6.33 was heated at 800 °C for 1 day. The pellet had spots of bright blue on its top. Since the α-phase did not form at temperatures below 750 °C, the β-phase was formed at temperatures above 800 °C. SMM6.33 was heated at 850 °C for 1 day. The pellet had shades of blue and green on its top. SMM6.33 was heated at 900 °C for 1 day. The pellet was bright blue and green with a glossy B2O3 top. The bottom and sides of the pellet were light purple. The bottom of the pellet was cracked. SMM6.33 was ground and pelletized. SMM6.33 was heated at 900 °C for 1 day. The lavender pellet was ground and pelletized once again. SMM6.33 was heated at 900 °C for 3 days. The XRD pattern, shown in Fig. 9, shows the reported high temperature, orthorhombic β-form, with lattice parameters a = 7.626(3) Å, b = 10.839(2) Å, and c = 13.517(3) Å, in good agreement with literature values.8 15 Two impurity peaks are also present in the XRD; one was identified as CuO, but the other could not be identified. 2500 I (Counts/s) 2000 Sr2Cu(BO3)2 CuO Unidentified SMM6.33 1500 1000 500 0 0 20 40 60 80 100 o 2θ ( ) Fig. 9: Cu Kα x-ray powder diffraction pattern of Sr2Cu (BO3)2, sample SMM6.33. The solid curve is intensity I versus diffraction angle 2θ. The space group is orthorhombic Pnma (#62) with a = 7.626(3) Å, b = 10.839(2) Å, and c = 13.517(3) Å. Impurity CuO (•) and unidentified (o) reflections are indicated. III. DISCUSSION AND RESULTS SrCu2(BO3)2 Magnetization measurements on the compound SrCu2(BO3)2 provide information about the features of the spin-singlet ground state and the magnetic excited states.3 Magnetization M versus field H for SMM7.41 is shown in Fig. 10 and for SMM8.43 in Fig. 11. The saturation magnetization Ms was obtained from fits to the high field data (1 to 5 T). Ms for sample SMM7.41 was set to zero after considering the significance of the error and the parameter ranges 16 used in the fit. The Ms(0) values obtained were very small and oscillated about zero, depending on the range of temperatures fit. The error bars were on the order of ± ~0.009 Gcm3/mol. The insignificance of these values compared to the data made it possible to assume that the range of parameters caused more of an error than was actually reported in the fit, and allowed us to set Ms(0) to zero for all temperatures. A zero value for Ms signifies no detectable ferromagnetic impurities present in magnetization M. Fig. 12 shows Ms versus T for sample SMM8.43. A linear fit yielded an average saturation magnetization Ms(0)ave of 0.119(7) Gcm3/mol. This value was subtracted from the magnetization M versus temperature T data to eliminate the ferromagnetic impurity contribution. 300 M (Gcm3/mol) 250 200 SrCu2(BO3)2, SMM7.41 300 K 200 K 100 K 50 K 150 5K 1.8 K 100 50 0 0 1 2 3 H (T) 4 5 6 Fig. 10: Magnetization M versus field H for SrCu2(BO3)2, sample SMM7.41 at 1.8 K (∆), 5 K (+), 50 K (×), 100 K (♦), 200 K ( ), and 300 K (~). 17 300 3 M (Gcm /mol) 250 200 150 SrCu2(BO3)2, SMM8.43 300 K 250 K 200 K 150 K 100 K 50 K 5K 100 50 0 0 1 2 3 H (T) 4 5 6 Fig. 11: Magnetization M versus field H for SrCu2(BO3)2, sample SMM8.43 at 5 K (ϖ), 50 K (∆), 100 K (+), 150 K (×), 200 K (♦), 250 K ( ), and 300 K (~). The magnetic susceptibility χ(T) was calculated from the following formula: χ (T ) = M − M s (T ) H app , (2) where Happ is the applied magnetic field (10 kOe). The magnetic susceptibility, shown for sample SMM7.41 in Fig. 13 and SMM8.43 in Fig. 14, shows a strong dependence on temperature. This most likely signifies the geometric frustration experienced by the system.6 Another characteristic is a significant, rapid decrease in χ with decreasing temperature at around 20 K. This suggests the presence of a spin gap3 rather than long-range antiferromagnetic order. 18 0.16 0.15 SrCu2(BO3)2, SMM8.43 0.13 3 Ms (Gcm /mol) 0.14 0.12 0.11 0.10 Fit: Ms = Ms(0) + bT 0.090 0.080 0 3 Ms(0) = 0.119(7) Gcm /mol 50 100 150 200 T (K) 250 300 350 Fig. 12: Saturation magnetization Ms versus temperature T for SrCu2(BO3)2, sample SMM8.43. The solid line is a fit to the data by the function shown in the figure, yielding the Ms(0) parameter also shown in the figure. χ(T) above 100 K was fitted to the Curie-Weiss law, χ = χo + C T −θ , (3) where θ is the Weiss temperature and C is the Curie constant, given by Ng 2 µ B2 S ( S + 1) C= , 3k B (4) in which N is the number of spins in the sample, g is the effective g-factor, µB is the Bohr magneton, S is the spin of the Cu2+ ion (assumed to be ½), and kB is the Boltzmann constant. In the units of Figs. 10-17, N is set to NA (Avogadro’s number). The temperature independent χo term is the sum of the contribution from the diamagnetic cores of the atoms, χcore, the 19 paramagnetic Van Vleck susceptibility of the Cu2+ ions, χVV, and the intrinsic spin susceptibility of SrCu2(BO3)2 at T = 0 K, χspin, χ o = χ core + χ VV + χ spin . (5) 0.006 SrCu2(BO3)2, SMM7.41 0.005 H = 10 kOe χ (cm3/mol) Data 0.004 High T Fit Low T Fit 0.003 Low T Fit, 1.8 - 5 K: −5 χ = 1.9x10 cm /mol 3 0 0.002 3 C = 0.005(1) cm K/mol θ = −1.6(6) K imp imp 0.001 High T Fit, 100 - 300 K: 3 χ = −0.00034(2) cm /mol 3 0 A = 0.14(2) cm /mol 3 C = 1.03(1) cm K/mol θ = −134(2) K T = 25.9(9) K g 0 0 40 80 120 160 T (K) 200 240 280 320 Fig. 13: Magnetic susceptibility χ versus temperature T for SrCu2(BO3)2, sample SMM7.41 (~). The solid line is the “High T Fit” to the data by Eq. (3), which yields the listed parameters. The dashed line is the “Low T Fit” to the data by Eq. (6), which yields the listed parameters. The fit to the data for sample SMM7.41 yielded θ = −134(2) K, C = 1.03(1) cm3K/mol, g = 1.66 per Cu atom, and χo = −0.00034(2) cm3/mol. The fit to the high temperature data for sample SMM8.43 yielded θ = −137(2) K, C = 1.05(1) cm3K/mol, g = 1.68 per Cu atom, and χo = −0.00036(2) cm3/mol. These g values are lower than expected for cuprates, indicating a deficiency in the Curie-Weiss model for this temperature region. Also, χo is larger than the χcore value of −1.23 × 10-4 cm3/mol,15,16 which is unphysical. Another indication that the model is 20 only approximately representing the data is that the parameters were strongly dependent on the temperature range that was fit. The anisotropic Heisenberg model includes only the intradimer exchange interaction J. For the geometrically frustrated system of orthogonal Cu2+ dimers that SrCu2(BO3)2 exhibits, the interdimer exchange interaction J′ must also be included. 0.006 SrCu2(BO3)2, SMM8.43 0.005 H = 10 kOe χ (cm3/mol) Data 0.004 High T Fit Low T Fit 0.003 Low T Fit, 1.8 - 5 K: χ = −0.0002(2) cm3/mol 0 0.002 C = 0.007(2) cm3K/mol θ = −2.5(7) K imp imp 0.001 High T Fit, 100 - 300 K: χ = −0.00036(2) cm3/mol 3 A = 0.14(2) cm /mol 0 3 C = 1.05(1) cm K/mol θ = −137(2) K T = 26.4(8) K g 0 0 40 80 120 160 T (K) 200 240 280 320 Fig. 14: Magnetic susceptibility χ versus temperature T for SrCu2(BO3)2, sample SMM8.43 (~). The solid line is the “High T Fit” to the data by Eq. (3), which yields the listed parameters. The dashed line is the “Low T Fit” to the data by Eq. (6), which yields the listed parameters. The data for samples SMM7.41 and SMM8.43 below 5 K were fit using χ = χo + Cimp T − θ imp + Ae − Tg T , (6) where Ae-Tg/T is the low temperature approximation of the intrinsic magnetic susceptibility for SrCu2(BO3)2. A is a proportionality constant and Tg = ∆/kB, where ∆ is the spin gap. The upturn, 21 which is due to paramagnetic impurities in the sample and/or structure defects, producing nearlyfree paramagnetic Cu2+ ions,3 is fit with the Curie-Weiss law. The fit for SMM7.41 gave θimp = −1.6(6) K, Cimp = 0.005(1) cm3K/mol, corresponding to 1.22% of nearly free S = ½ impurities and a spin gap ∆/kB = 25.9(9) K. The fit for sample SMM8.43 gave θimp = −2.5(7) K, Cimp = 0.007(2) cm3K/mol, corresponding to 1.77% of nearly free S = ½ impurities and a spin gap ∆/kB = 26.4(8) K. The values obtained for ∆/kB are in close agreement with published results.3,5,6,17 Sr2CuO3 3.5 M (Gcm3/mol) 3.0 2.5 2.0 1.5 Sr2CuO3, SMM6.33 300K 250K 200K 100K 50K 1.0 0.5 0.0 0 1 2 3 H (T) 4 5 6 Fig. 15: Magnetization M versus field H for Sr2CuO3, sample SMM6.33 at 50 K (+), 100 K (×), 200 K (♦), 250 K ( ), and 300 K (~). Orthorhombic Sr2CuO3 was made as an intermediate material in the synthesis of βSr2Cu(BO3)2. Magnetization M is shown as a function of field H in Fig. 15. The saturation 22 magnetization Ms(0) values were obtained as before and Ms versus T is shown in Fig. 16. Data from 5 K, 100 K, and 150 K were not included. The unweighted fit produced an average saturation magnetization Ms(0)ave of 0.003(2) Gcm3/mol. This value was subtracted from the M versus T data to eliminate the ferromagnetic impurity contribution to the susceptibility. 0.035 0.030 Sr CuO , SMM6.33 2 3 s M (Gcm3/mol) 0.025 0.020 Fit: M = M (0) + bT 0.015 s s M (0) = 0.003(2) Gcm3/mol 0.0100 s 0.0050 0.0 -0.0050 0 50 100 150 200 Temp (K) 250 300 350 Fig. 16: Saturation magnetization Ms versus temperature T for Sr2CuO3, sample SMM6.33. The solid line is a fit to the data by the function shown in the figure, yielding the Ms(0) parameter also shown in the figure. The magnetic susceptibility χ(T) is shown in Fig. 17. The data from 1.8 to 100 K were fit to the Curie-Weiss law, Eq. 3, yielding θ = −1.37(3) K, C = 0.00148(1) cm3K/mol, and χ0 = 2.36(5) × 10−5 cm3/mol. The core contribution to the magnetic susceptibility χcore was calculated to be −7.70 × 10−5 cm3/mol.15 The Curie constant corresponds to 0.39% nearly-free spin ½ paramagnetic impurities. 23 0.0005 Sr2CuO3, SMM6.33 H = 10 kOe 0.0004 3 χ (cm /mol) Fit: 1.8 - 100 K 0.0003 χ = χ0 + Cimp/(T − θimp) −5 χ0 = 2.36(5)x10 cm /mol 3 0.0002 0.0001 0 0 3 Cimp = 0.00148(1) cm K/mol θimp = -1.37(3) K 40 80 120 160 T (K) 200 240 280 320 Fig. 17: Magnetic susceptibility χ versus temperature T for Sr2CuO3, sample SMM6.33 (~). The solid curve is a fit to the data by the function shown in the figure [Eq. (3)], with parameters also listed in the figure. β-Sr2Cu(BO3)2 Fig. 18 shows M versus H isotherms for β-Sr2Cu(BO3)2. Fits of the high field data (1 to 5 T) yielded Ms = 0. The magnetic susceptibility is shown in Fig. 19. At first glance, the curve highly resembles that for SrCu2(BO3)2. However, a closer analysis of Fig. 2 confirms that the nearest-neighbor intradimer exchange interaction bond length is approximately 4.27 Å. This relatively large Cu2+ bond length is a sign that the intradimer interaction is not very big, compared with that for SrCu2(BO3)2. The fact that the Cu2+ dimers are isolated8 suggests that the interdimer exchange interaction is small enough to essentially be ignored. The data was therefore fit to a mean field spin dimer model plus an impurity Curie-Weiss term, 24 χ = χ0 + C imp T − θ imp + 1 N Aµ g k BT 2 B 2 1 Tg T + e 3 +λ , (8) where λ is the mean field coupling constant and g was fixed at 2. The term λ takes the interdimer exchange interaction into account in the fitting constraints, and therefore the fit represents the data completely. The fit yielded θimp = −1.3(1) K, Cimp = 0.00164(6) cm3/mol, corresponding to 0.44% of nearly free S = ½ impurities, λ = 26.1(5) mol/cm3, ∆/kB = 100.2(1) K, and χ0 = −5.8(3) × 10-5 cm3/mol. The core contribution to the magnetic susceptibility χcore was calculated to be −1.274 × 10−4 cm3/mol.15,16 Allowing the g value to vary resulted in a fit that was not quite as accurate as the one presented and a g value less than 2. 150 100 300 K 200 K 100 K 50 K 3 M (Gcm /mol) β-Sr2Cu(BO3)2, SMM6.33 5K 1.8 K 50 0 0 1 2 3 H (T) 4 5 6 Fig. 18: Magnetization M versus field H for β-Sr2Cu(BO3)2, sample SMM6.33 at 1.8 K (∆), 5 K (+), 50 K (×), 100 K (♦), 200 K ( ), and 300 K (~). 25 0.0030 β-Sr Cu(BO ) , SMM6.33 2 3 2 χ (cm3/mol) 0.0025 H = 10 kOe Fit: χ = χ0 + Cimp/(T − θimp) + 0.0020 spin dimer with mean field approx. 0.0015 0.0010 0.00050 −5 Tg = 100.2(1) K 3 3 Cimp = 0.00164(6) cm K/mol λ = 26.1(5) mol/cm θ g = 2, fixed imp 0.0 0 3 χ = −5.8(3)x10 cm /mol 0 40 = −1.3(1) K 80 120 160 T (K) 200 240 280 320 Fig. 19: Magnetic susceptibility χ versus temperature T for β-Sr2Cu(BO3)2, sample SMM6.33 (~). The solid curve is a fit to the data by the function shown in the figure [Eq. (8)], with parameters also listed in the figure. IV. SUMMARY AND CONCLUSIONS We conclude that the powdered B2O3 used to synthesize sample SMM1.2 is not a reliable material to use because of its unknown water content. The anhydrous B2O3 used to make the remaining samples was found to be much more effective. We determined a dependable method for synthesis of SrCu2(BO3)2 with the hard, glassy B2O3 in order to make a single phase compound. We have studied the magnetic properties of the compounds SrCu2(BO3)2, Sr2CuO3, and β-Sr2Cu(BO3)2. The properties of our SrCu2(BO3)2 samples agree with the literature.3,5 The high temperature data was fit to the Curie-Weiss law, resulting in θ = −134(2) K, C = 1.03(1) 26 cm3K/mol, g = 1.66 per Cu atom, and χo = −0.00034(2) cm3/mol. The low temperature data was fit to the Curie-Weiss law plus the low temperature approximation for χspin, giving θimp = −1.6(6) K, Cimp = 0.005(1) cm3K/mol, and a spin gap of ∆/kB = 25.9(9) K. In addition, this compound was found to have no reaction with water for approximately 1 to 2 days, which makes it a possible candidate for electrochemical doping. The compound β-Sr2Cu(BO3)2, which was well fitted by the mean field spin dimer model, is a system of nearly isolated Cu2+ dimers. The interaction between dimers cannot be ignored, but it is very weak. The fit gave θimp = −1.3(1) K, Cimp = 0.00164(6) cm3/mol, λ = 26.1(5) mol/cm3, ∆/kB = 100.2(1) K, and χ0 = −5.8(3) × 10-5 cm3/mol when g = 2. The magnetic properties of this compound, to our knowledge, have not previously been reported in the literature. ACKNOWLEDGMENTS Ames Laboratory is operated for the U.S. Department of Energy by Iowa State University under Contract No. W-7405-Eng-82. This work was supported by the Director for Energy Research, Office of Basic Energy Sciences. The Iowa State University Research Experience for Undergraduates was funded by the National Science Foundation. REFERENCES 1 A. Kawaguchi, A. Koga, K. Okunishi, and N. Kawakami, J. Phys. Chem. Solids 63, 1431 (2002). 2 B. S. Shastry and B. Kumar, cond-mat/0204228. 3 H. Kageyama, K. Yoshimura, R. Stern, N. V. Mushnikov, K. Onizuka, M. Kato, K. Kosuge, C. 27 P. Slichter, T. Goto, and Y. Ueda, Phys. Rev. Lett. 82, 3168 (1999). 4 R.W. Smith and D. A. Keszler, J. Solid State Chem. 93, 430 (1991). 5 S. Miyahara and K. Ueda, Phys. Rev. Lett. 82, 3701 (1999). 6 H. Kageyama, M. Nishi, N. Aso, K. Onizuka, T. Yosihama, K. Nukui, K. Kodama, K. Kakurai, and Y Ueda, Phys. Rev. Lett. 84, 5876 (2000). 7 B. S. Shastry and B. Sutherland, Physica B 108, 1069 (1981). 8 R. W. Smith and D. A. Keszler, J. Solid State Chem. 81, 305 (1989). 9 J. M. Hill, D. C. Johnston, and L. L. Miller, Phys. Rev. B 65, 134428 (2002). 10 S. L. Strong and R. Kaplow, Acta Crystallogr., Sec. B 24, 1032 (1968). 11 S. V. Berger, Acta Crystallogr. 5, 389 (1952). 12 M. Gajhede, S. Larsen, and S. Rettrup, Acta Crystallogr., Sec. C 42, 545 (1986). 13 T. A. Vanderah, R. S. Roth, and H. F. McMurdie, Phase Diagrams for High Tc Superconductors II (The American Ceramic Society, Westerville, Ohio, 1997). 14 T. Ami, M. K. Crawford, R. L. Harlow, Z. R. Wang, D. C. Johnston, Q. Huang, and R. W. Erwin, Phys. Rev. B 51, 5994 (1995). 15 P. W. Selwood, Magnetochemistry (Interscience, New York, 1956), 2nd ed. 16 E. Konig and G. Konig, in Landolt-Bornstein: Numerical Data and Functional Relationships in Science and Technology, edited by K.-H. Hellwege and A. M. Hellwege (Springer-Verlag, Berlin, 1976), vol. 8. 17 H. Kageyama, K. Onizuka, Y. Ueda, N.V. Mushnikov, T. Goto, K. Yoshimura, and K. Kosuge, J. Phys. Soc. Jpn. K. Sparta, G. J. Redhammer, P. Roussel, G. Heger, G. Roth, P. Lemmens, A. Ionescu, M. Grove, G. Guntherodt, F. Huning, H. Lueken, H. Kageyama, K. Onizuka, Y. Ueda, cond-mat/0012383. 28