How do AGV Systems Work? On-Line Training Program Module 4b AGVS Product Section

advertisement

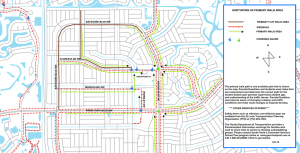

On-Line Training Program Module 4b How do AGV Systems Work? AGVS Product Section of MHI © 2012 MHI®. All rights reserved. Summary • • • • • • • Host computer/Server Graphical user interface Communication (RF, IR, Wire, etc) Order creation Traffic control Charging Integration into facility hardware (doors, conveyors and the like) and software (WMS, WCS, and the like) 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 System components Operator interfaces System controller AGV 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Host system OPC IO Common system functions • • • • • • • • • • • • Order handler AGV handler Traffic handler Digital I/O handler Communications – AGVs and other units Simulator Gather statistics Generate reports Diagnostics System visualization Backup and redundancy Black box / “Flight” recorder 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Server • Usually PC based • Network connected • Database backend • Backup 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Graphical user interface • Desktop, laptop or mobile device • Graphical overview of the system • Tracking of AGVs • Visualization of peripheral I/O units (OPC) • Event logs • Order buffer • System health • Statistics and reports 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Server connectivity • Connected to the AGVs through • Wireless network • Radio • Connected to other systems through • Ethernet • I/O • Utilizes OPC 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Basic communication with AGVs Server Traffic and order control Command to a location and perform an operation Vehicle position & status 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Flexible I/O with OPC Server can connect to an OPC server. OPC supports a number of field bus standards: CAN bus Profibus Interbus Devicenet….. Read about the standard at: www.opcfoundation.org 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Layout 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Layout Defined drive paths, where the AGVs are allowed to drive. Divided into segments/tracks and points – The points are valid targets – The segments are parts of the drive paths Some systems use stations where load operations are allowed 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Layout-less systems Some systems run without a layout created in a definition tool These systems are typically based on magnetic tape or wire guidance 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 System Control Choose best AGV for transport Routing; Choose best path Manage blocking – Other AGVs in the drive path – Stationary equipment (automatic doors, stretch wrappers and the like) 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Traffic rules - Blocking • To maximize the movement of AGVs, there must be a set of rules that meters the flow of AGV traffic and eliminates the potential for traffic jams. This is often called blocking. • Before the AGV is allowed to drive on the calculated path, it is checked to make sure that the path is free using the traffic rules set up for the system. The path, or a suitable part of the path, will then be allocated to that AGV. • Auxiliary blocking will control the AGV as it interacts with external objects (doors, active machines, and the like). This is achieved by interacting with the objects through OPC or other I/Os. 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Traffic decision points - Blocking A second approach to blocking involves decision points or tags Every time an AGV passes a tag, a script is run to evaluate the traffic situation and destination before acting accordingly 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Order handler – Manages order assignment to AGVs Simple transports – Move container from location A to location B More complex multi-part order - Pick order – Move AGV through warehouse while operator manually places goods on the pallet. Automatically moves AGV to finish point when complete. Automatically deploys new AGV when needed. Charging – Move AGV to charger when AGV is idle or needs power and charger is available. Idling – Manages AGVs that have no order 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Order • An order defines one or several movements, to be executed by the AGV • A typical order contains a pick-up-location and a dropoff-location • When used in a pick application, an order may contain several stops, where items are manually added to AGV 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Charging • An automatic order for an AGV to go charge can be generated by the system • Low voltage may trigger a charge • Opportunity charging may also be used based on: • AGV being idle • AGV being close to a charger • Other customizable triggers 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Programmability • PLC or scripts on system level • Customized logic • Events and alarms • Debugging • Interaction with host systems 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Host Integration • AGV orders are commonly initiated by a host system such a WMS, WCS, MES or ERP (*) • Standard or custom interfaces are defined for the host system to start orders, move AGVs and other tasks • Integration options include standards such as SQL databases, message queues (MQ), Web services, FTP, TCP/IP sockets and more * WMS = Warehouse Management System, WCS = Warehouse Control System, MES = Material Execution System, ERP = Enterprise Resource Planning system 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 Handling of Idle AGVs • Home location • A home location is a place where the AGVs go when not executing orders. • Queues, parking and intermediate locations 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 AGV Allocation • The best AGV for a specific order may be selected by the system manager • Host systems may select an AGV for an order • AGVs can manually be selected 8720 Red Oak Blvd., Suite 201 | Charlotte, NC 28217-3992 USA Phone: (704) 676-1190 | FAX: (704) 676-1199 For More Information: Contact the AGVS Product Section of MHI http://www.mhi.org/agvs © 2012 MHI®. All rights reserved.