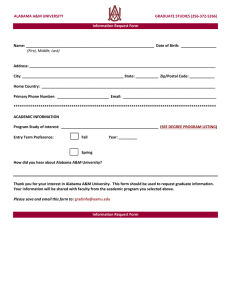

ALABAMA A&M UNIVERSITY NOTICE AND INSTRUCTIONS TO BIDDERS

advertisement