Author(s) Marino, Stephen A.

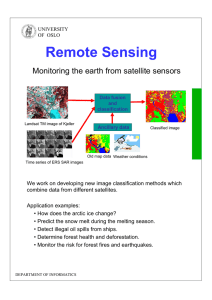

advertisement

Author(s)

Marino, Stephen A.

Title

Operation and calibration of the NPS Ultraviolet Imaging Spectrometer (NUVIS) in the

detection of sulfur dioxide plumes

Publisher

Monterey, California. Naval Postgraduate School

Issue Date

1999-12-01

URL

http://hdl.handle.net/10945/8773

This document was downloaded on May 04, 2015 at 23:43:18

MONTEREY CA

93943-5101

NAVAL POSTGRADUATE SCHOOL

Monterey, California

THESIS

OPERATION AND CALIBRATION OF THE NPS

ULTRAVIOLET IMAGING SPECTROMETER (NUVIS)

LN THE DETECTION OF SULFUR DIOXIDE PLUMES

by

Stephen A. Marino

December 1999

Thesis Advisers:

David

S.

Davis

Richard C. Olsen

Approved

for public release; distribution

is

unlimited.

REPORT DOCUMENTATION PAGE

Public reporting burden for this collection of information

is

estimated to average

1

Form Approved

OMB No.

0704-0188

hour per response, including the time for reviewing instruction, searching

existing data sources, gathering and maintaining the data needed, and completing and reviewing the collection of information.

Send comments regarding

this

burden estimate or any other aspect of this collection of information, including suggestions for reducing this burden, to Washington headquarters Services,

Directorate for Information Operations and Reports. 1215 Jefferson Davis Highway, Suite 1204. Arlington, VA 22202-4302, and to the Office of Management

and Budget Paperwork Reduction Project (0704-0188) Washington DC 20503.

1.

AGENCY USE ONLY (Leave blank)

2.

REPORT DATE

3.

December 1999

REPORT TYPE AND DATES COVERED

Master's Thesis

TITLE AND SUBTITLE OPERATION AND CALIBRATION OF THENPS

ULTRA VIOLET IMAGING SPECTROMETER (NUVIS) IN THE DETECTION OF

SULFUR DIOXIDE PLUMES

4.

6.

5.

FUNDING NUMBERS

AUTHOR(S)

Marino, Stephen A.

7.

PERFORMING

ORGANIZATION REPORT

8.

PERFORMING ORGANIZATION NAME(S) AND ADDRESS(ES)

Naval Postgraduate School

Monterey, CA 93943-5000

9.

NUMBER

SPONSORING / MONITORING AGENCY NAME(S) AND ADDRESS(ES)

10.

AGENCY REPORT NUMBER

N/A

11.

SPONSORING / MONITORING

SUPPLEMENTARY NOTES

The views expressed

in this thesis are

those of the author and do not reflect the official policy or position of the Department of

Defense or the U.S. Government.

12a.

DISTRIBUTION / AVAILABILITY STATEMENT

Approved

13.

for public release; distribution

is

12b.

DISTRIBUTION CODE: A

unlimited.

ABSTRACT (maximum 200 words)

The Naval Postgraduate School's Ultraviolet Imaging Spectrometer (NUVIS) is a hyperspectral sensor with a spectral

response of 300 to 375 nanometers. This thesis research concentrates on the operation and calibration of NUVIS in the

detection of effluent sulfur dioxide (S0 2 ) plumes. NUVIS is capable of detecting and quantifying S0 2 emissions in the

form of effluent smokestack plumes by exploiting S0 2 's unique UV absorption signature. Laboratory comparison UV

spectra of S0 2 were recorded and used to calculate curves of growth for four different S0 2 spectral features. Laboratory

results were employed to analyze field data taken of a coal-burning power plant. Analysis of this plume data yielded a

mean plume S0 2 mixing

assessment of

NUVIS

365 ± 200 ppm,

ratio of

indicates that

its

in

lower limit for

agreement with the

S0 2

in situ stack

value of 400 ppm.

detection in typical field applications

is

Further

approximately 70

ppm.

14.

SUBJECT TERMS

Ultraviolet, Hyperspectral, Spectral Imaging, Spectrometer, Sulfur Dioxide, Pollution,

Remote

15.

Sensing, Environmental Monitoring

17.

SECURITY CLASSIFICATION OF

REPORT

Unclassified

NUMBER OF

PAGES

104

SECURITY CLASSIFICATION

16.

PRICE CODE

LIMITATION OF

19. SECURITY

CLASSIFICATION OF

20.

OF THIS PAGE

Unclassified

ABSTRACT

UL

18.

ABSTRACT

Unclassified

NSN

7540-01-280-5500

Standard Form 298 (Rev. 2-89)

ANSI Std. 239-18

Prescribed by

11

DUDLEY KNOX LIBRARY

N ^VAL POSTGRADUATE

SCHOOL

B

MONTEREY, CA 93943-5101

Approved

for public release; distribution

is

unlimited

OPERATION AND CALIBRATION OF THE NPS ULTRAVIOLET IMAGING

SPECTROMETER (NUVIS) IN THE DETECTION OF SULFUR DIOXIDE

PLUMES

Stephen A. Marino

Lieutenant, United States

B.S., University

Submitted

Navy

of Pittsburgh, 1991

in partial fulfillment

of the

requirements for the degree of

MASTER OF SCIENCE IN APPLIED PHYSICS

from the

NAVAL POSTGRADUATE SCHOOL

December 1999

DUDLFY KNOX LIBRARY

POSTGRADUATE SCHOOL

MONTEREY CA 93943-5101

ABSTRACT

The Naval Postgraduate School's

Ultraviolet

Imaging Spectrometer (NUVIS)

a hyperspectral sensor with a spectral response of 300 to 375 nanometers.

thesis research concentrates

on the operation and calibration of

detection of effluent sulfur dioxide (SO2) plumes.

and quantifying SO2 emissions

exploiting S02's unique

spectra of

different

UV

in the

absorption signature.

spectral features.

value of 400 ppm.

SO2

ratio

in the

capable of detecting

Laboratory comparison

to calculate curves

UV

of growth for four

Laboratory results were employed to analyze field

data taken of a coal-burning power plant.

mean plume SO2 mixing

is

This

form of effluent smokestack plumes by

SO2 were recorded and used

SO2

NUVIS

NUVIS

is

Analysis of this plume data yielded a

of 365 ± 200 ppm, in agreement with the

Further assessment of

detection in typical field applications

NUVIS

is

indicates that

its

approximately 70 ppm.

in situ stack

lower limit for

VI

TABLE OF CONTENTS

INTRODUCTION

I.

MOTIVATION AND OBJECTIVES

OUTLINE

A.

B.

II.

1

1

4

BACKGROUND

REMOTE SENSING AND SPECTRAL IMAGING

A.

ULTRAVIOLET REMOTE SENSING

B.

1.

2.

C.

1.

2.

D.

III.

The Concept

Earth's Atmosphere and

7

7

12

12

Ultraviolet

Wavelengths

13

SULFUR DIOXIDE

15

An Atmospheric Pollutant

An Ultraviolet Absorber

ABSORPTION SPECTROSCOPY

15

18

20

1.

Introduction

20

2.

Terminology

3.

The Curve of Growth

22

26

NUVIS

29

A.

BACKGROUND

29

B.

OPTICAL, OPTOMECHANICAL AND ELECTRONIC HARDWARE

THE COMPUTER, DATA ACQUISITION AND CONTROL SYSTEMS

29

C.

D.

DATA ACQUISITION, CONTROL AND DATA DISPLAY SOFTWARE

35

IV.

LABORATORY CALIBRATIONS OF NUVIS

32

41

A.

PURPOSE

41

B.

WAVELENGTH CALIBRATION

EXPERIMENTAL OVERVIEW

41

C.

43

LABORATORY MEASUREMENTS OF S0

D.

1.

Gas Test

45

2.

Calibration Source and Reflective Screen

49

3.

Test Cell Preparation

51

4.

Data Acqusition

52

5.

First Results

.

GENERATING EXPERIMENTAL CURVES OF GROWTH

E.

53

55

1.

Approach

55

2.

Experimental Results

56

3.

Analysis of Experimental Data

59

APPLICATION OF LABORATORY CALIBRATIONS TO FIELD DATA

V.

44

2

Cells

63

A.

FIELD EXPERIMENTS

63

B.

RESULTS

67

VI.

CONCLUSIONS AND RECOMMENDATIONS

vii

75

APPENDIX A. NUVIS FIELD CHECKLIST

79

APPENDIX

B.

NUVIS OPERATIONAL CHECKLIST

81

APPENDIX

C:

RANGE EFFECTS AND NUVIS ANOMALIES

87

LIST OF

REFERENCES

91

INITIAL DISTRIBUTION LIST

93

Vlll

ACKNOWLEDGEMENTS

The author would

motivator in

my

Stephen Finney,

analysis.

thank Dr. David Geary whose enthusiasm was a major

decision to begin this

USAF,

Thanks

to

during this research.

love, devotion

like to

work with NUVIS.

Special thanks to Major

for assisting in the 1999 field experiments

NPS

staff

and subsequent data

members Jay Adeff and Don Snyder

Finally, the author

would

and patience.

IX

like to

for their support

thank his wife, Michelle, for her

INTRODUCTION

I.

MOTIVATION AND OBJECTIVES

A.

Remote sensing instruments

are critical to the areas of technical intelligence, the

remote sensing of hazards, and support to military operations. In an

capabilities available to the

pursued a

we have

came, in

Analysis

remote sensing community as well as

used portion of the electromagnetic spectrum.

little

part,

Over

wavelengths.

we have

the last three years,

Our motivation

from the success of the school's Middle Ultraviolet SpecTrograph

of Nitrogen

Spectrometer

enhance the

to the military,

designed and constructed an ultraviolet hyperspectral imager.

instrument.

This

Gases

resulted

(NUVIS),

NUVIS

is

a

in.

(MUSTANG),

the

rocket-borne

research

UltraViolet

Imaging

NPS

imager

operates

first

that

for

atmospheric

development of the

hyperspectral

one of the

a

at

near-ultraviolet

such instruments of its kind: a portable, ground-

based, hyperspectral imager that operates at ultraviolet

to

effort to

(UV) wavelengths: nominally 300

375 nanometers (nm).

From

the onset,

NUVIS

designers recognized that ultraviolet remote sensing

could be used as an important tool in effluent analysis. Through the efforts of Dr. David

Cleary,

LT Todd Hooks and Major Andrew MacMannis, NUVIS was

school, and fabrication of the instrument

was

to focus research

effluent plume.

communities.

was completed

on the instrument's

Such

ability to

in the fall

designed

at the

of 1997. The next step

analyze and characterize a chemical

capabilities are of interest to both the civilian

and military

As

testing

initial

was about

to get

underway, a major question arose: Could

gaseous effluents emitted from smoke stacks be detected, imaged, identified, and

quantified using hyperspectral remote sensing techniques at

thesis research set out to

answer

that question

capability to perform such a mission.

dioxide

(S0 2 ), was

Numerous

using

and

UV

wavelengths?

This

to further define the instrument's

In support of these efforts, the trace gas, sulfur

targeted for study.

studies have focused

spectroscopic

monitoring

on the topic of remote sensing of trace gases

Supporting

techniques.

literature

indicates

that

considerable attention has been placed on the study and techniques of infrared remote

sensing. Until

little

attention.

now, remote sensing

at ultraviolet

wavelengths has received compartively

This study sets out to challenge such thinking by exploring

new ways

to

exploit the ultraviolet region of the electromagnetic spectrum utilizing the recently

developed technique of hyperspectral imaging.

Although

ultraviolet

ozone absorption than do

wavelengths suffer more from atmospheric scattering and

others,

study

this

will

show

that

demonstrated dual-use imaging and spectroscopic capabilities and

at short range, the effluent trace

determine whether effluent

longer distances using

UV

S0

2

gas

S0

2

.

With

this initial success,

NUVIS

is

it

has

already

capable of detecting,

became necessary

to

could reliably be identified, measured and quantized over

remote sensing.

An

approach was taken such that laboratory

experiments, calibrations, and operational field testing would lead to an evaluation of

NUVTSTs

capabilities to detect the trace gas

and the

utility

of such technology.

This thesis project focuses on calibrating the spectrometer for the detection of

gaseous sulfur dioxide. Laboratory experiments were conducted

of S0 2 to measure changes

SO2

is

in its absorption

at

known

concentrations

spectrum as a function of gas concentration.

a triatomic molecule that has a set of strong absorption signatures between 300

and 325 nm.

The

number of

detailed spectrum across this spectral region exhibits a

For each observed

identifiable absorption lines.

spectral absorption, called

its

equivalent width,

line,

may be

an associated measure of

easily measured.

its

Calibration

curves of the lines' equivalent widths versus gas concentration, called curves of growth,

can then be generated.

During

analysis,

four

this research,

six sets

of calibration data were analyzed.

absorption

individual

lines

were

identified

for

From

equivalent

this

width

measurements. Four curves of growth were successfully generated from these laboratory

experiments.

These calibration curves were then applied to

attempt to quantify effluent

It

all

S0 2

should be noted that

of the instrument's

initial

the process of leaving.

field data in

an

concentrations.

my

involvement with

designers had either

Because of

this,

NUVIS came

moved on from

at a

time when nearly

the school or were in

a period existed where Dr. Cleary had done a

considerable amount of work with the instrument himself, and the majority of this

had gone unpublished.

initial

work

Because Hooks and MacMannis were unable to complete

laboratory and field testing of the instrument, a detailed operating procedure had not yet

been developed. This

thesis will not only present the

work involved with generating

the

S0 2

curves of growth but will also outline the basic operating procedures for the

Such documentation had not existed

instrument.

prior to this study.

an attempt to maintain continuity with the work done by Hooks and

In

MacMannis,

this thesis also includes certain portions

as background material. This

is

due to the

in part

undergone certain improvements from

inclusion of such material

In

1998,

is

its

of Dr. Geary's unpublished work

original configuration.

experiments

were

preliminary spectroscopy and spectral imagery of effluent

accompanying

data analysis have

resultant

detection,

analysis

is

appropriate, the

all

conducted

and resulted

S0 2 -producing

targets.

calibration, a follow-on field experiment,

been accomplished

in

and characterization with respect

involved in this study

Where

system has

clearly indicated.

ground-based field

thesis research, the

NUV1S

fact that the current

a follow-on to the

initial

to

This

and the

support of chemical plume

The work

sulfur dioxide.

experimental research initiated in 1998.

OUTLINE

B.

This thesis

is

divided into six chapters and three appendices.

the necessary background material

on

Chapter

the topics of remote sensing

II

provides

and hyperspectral

imaging, ultraviolet remote sensing, sulfur dioxide and absorption spectroscopy.

NUVIS

instrument will be presented in Chapter

calibration

S0 2

in

III.

The

Chapter IV details the laboratory

of NUVIS and includes resultant curves of growth, one for each of the four

absorption lines selected for analysis.

Field data

is

briefly analyzed

application of these laboratory calibrations developed in Chapter IV.

by a simple

This process and

the

accompanying

results are presented in

are contained in Chapter VI.

field operation.

Appendix

B

Appendix

Chapter V. Conclusions and recommendations

A provides

a

recommended

checklist for

briefly details the system operating procedure.

provides additional data that should be considered in future reasearch.

NUVIS

Appendix C

THIS PAGE INTENTIONALLY LEFT

BLANK

BACKGROUND

II.

REMOTE SENSING AND SPECTRAL IMAGING

A.

Remote sensing

at a

a generic term used to describe

is

distance from an object to be observed.

is

carried

If the source

If the source

remote sensing (Lenoble,

is

a

man-made

lists

some

emitter, then the process

of these waves

1993).

It

wavelengths (200-400nm) with which

Table 2.1

Typically the information being

by electromagnetic waves, although other means are sometimes used.

of these waves

remote sensing.

of the measurements made

involves collecting information about an

It

object without being in direct contact with that object.

collected

all

is

is

NUVIS

is

sensing

dubbed active

known

natural, the process is

passive remote

is

at

as passive

near-ultraviolet

most concerned. As a quick reference,

typical wavelength, frequency

and wavenumber ranges for various

regions of the electromagnetic spectrum.

Name

Wavelengths

Frequencies

(nm)

(Hz)

8

13

Radio

~10 -10

Microwave

~10 7 -10 8

Infrared

~10 3 -10 7

700-400

Visible

4

~3x 10 -3x 10

-3xl0 9 -3x 10 10

~3x 10 10 -3x 10 14

4

-400-50

-7.5 x 10' -6.0x 10

XRay

Gamma Ray

-50-0.1

-(0.6-300) x 10

<0.1

To3x

2. 1.

10

1

)

10' -0.1

0.1-1

1-10

14

Ultraviolet

Table

(cm"

6

9

-(4.3-7.1) x 10

Wavenumbers

4

(1.4-2.4)

15

16

18

x 10

(2.5-20) x 10

4

4

(0.2-100) x 10

>10

6

8

Typical wavelengths, frequencies and wavenumbers for various regions of the

electromagnetic spectrum.

Over the

last

decade, a

number of instrument platforms have been developed

the express purpose of optical remote sensing.

number of

field operations, ranging

based applications.

quickly

These platforms have been employed

from space-based and air-based missions

to

for

in a

ground-

Spectral imagers are one such instrument family, and they have

become workhorses of the remote sensing community.

Spectral imagers measure

both the 2-D image produced by a scene and the spectral content of each picture element

(pixel)

of the image.

These spectral imagers are

bands they record. Figure

2.1 provides a brief

The motivation behind

classified

by the width of the spectral

overview of such

the development of

classifications.

NUVIS was

a perceived need to

explore the near-UV wavelength region with an operational hyperspectral imager.

Such

an instrument would be capable of collecting data from tens to hundreds of bands

much

at

a

smaller bandwidth resolution than that of a conventional multispectral sensor.

WAVELENGTH (ran)

400

700

nil

MULTISPECTRAL

4000

2000

1000

6000

14000

aitifgii

Spectral identification of major features,

Wide Bandwidth

ije.,

trees, grass, roads

Moderate Spectral Resolution

HYPERSPECTRAL

Spectral discrimination by species

Narrow Bandwidth

High Spectral Resolution

materials, and environmental conditions

ULTRASPECRAL

Very Narrow Bandwidth

Very High Spectral Resolution

Figure

2. 1.

Spectral imager classifications.

Identification

and discrimination of subtle

spectral details of materials, vapors and aerosols

From

Multispectral Users Guide, 1995.

NUVIS

Related research that began in 1996 resulted in the

hyperspectral imager with a spectral bandwidth of 300 to 375

instrument of today, a

nm

at

a resolution of

approximately 0.3 nm. (Geary, 1998)

A

hyperspectral imager produces a spectral image of a scene, which

displayed in a format

known

use a two-dimensional array

a

CCD) and

typically

Imaging spectrometers typically

as a hyperspectral cube.

(e.g.,

is

produce the three-dimensional data cube

containing two spatial dimensions and a third spectral dimension. The third dimension

is

obtained by scanning either the spectral dimension or one of the two spatial dimensions.

NUVIS

is

the latter type.

illustrated in Figure 2.2.

A

sample of NUVIS output

A

large

number of images

demonstrated in the image cube

is

are created

from contiguous, rather

than disjoint regions of the spectrum. This technique typically yields finer resolution than

is

possible with a multispectral imager and in doing so, provides

to the data analyst.

energy

at a specific

It is

from

this series

much more

of images, each measuring the level of incident

wavelength, that a combined image

is

formed.

Today, countless airborne hyperspectral sensors are employed

2.2 provides a

summary of many of these

relative non-existence of

UV

information

instruments.

hyperspectral imagers.

in the field.

Table

This table also demonstrates the

Thus,

NUVIS

based, passive remote sensor capable of hyperspectral imaging at

is

a portable, ground

UV

wavelengths; a

prototype instrument that could someday possibly be employed as an airborne sensor.

Figure

2. 2.

NUVIS

hyperspcctral cube.

Image

illustrates the

two

dimension comprising the image cube.

10

spatial

and one spectral

Sensor

(Agency)

AAS (ASTER)

Number

Spectral

Bandwidth

IFOV

FOV

of Bands

Range(nm)

FWHM(nm)

(mrad)

(deg)

760-850

1

20

3000-5000

8000-12000

AHS.Daedelus

48

AIS-1

128

(DAIS-2815)(GER)

3

90

600-700

1.0,2.5,

or 5.0

Data

•

Period of

Operation

28.8,65

Image

Since(s)

,

Cube

1991

(IC)

440-12700

200

20-1500

2.5

86

IC

1994

990-2100

9.3

1.91

3.7

IC

1982-85

10.6

2.05

7.3

IC

1986-87

or 104

1200-2400

128

AIS-2

800-1600

1200-2400

(NASA/JPL)

1-286

450-900

AMSS

32

(Geoscan)

8

A1SA

1.56-9.36

1

21

IC

SI 993

490-1090

170-240

2.1x3.0

92

IC

SI 985

2020-8500-

430-440

12K

550-590

(KarelsilvaOy)

6

Sensor

Number

Spectral

Bandwidth

IFOV

FOV

(Agency)

of Bands

Range(nm)

atFWHM

(mrad)

(deg)

Data

Period of

Operation

(nm)

ARES

ASAS

(AIP)

Upgraded

ASAS

(NASA/GSFC)

AVIRIS (JPL)

CASI

75

2000-6300

25-70

1.17

3x3

IC

29

455-873

15

0.80

25

IC

62

400-1060

11.5

0.80

25

224

380-2500

9.7-12.0

1

30

IC

288

400-1000

650

1.3,1.6

37.8

Profile

44.7

Image

80deg

IC

SI 993

1992

19

nominal

CIS

64

400-1040

10

1.2x3.6

(China)

24

2000-2480

3530-3940

20

410

1000

1.2x1.8

(Itres

Research)

1

S1985

1987-91

S1991

S1987

SI 990

1.2x1.2

2

10.5K-12.5K

CHRISS,SAIC

40

430-860

11

0.05

10

IC

AHIS,(SAIC)

DAJS-7915

288

440-880

3

1.0

11.5

IC

1994

32

10-16

3.3,2.5,

64-78

IC

SI 994

8

400-1010

1500-1780

36

or5.0

32

1970-2450

3

78

IC

SI 994

5

±45

IC

SI 994

1.3

70

Profile

1984-90

(GER/DLR)

3000-5000

36

2000

6

8.7K-127K

600

1

DAJS-16115

(GER)

DA1S-3715

(GER)

76

400-1000

8

32

32

1000-1800

25

2000-2500

16

6

3000-5000

333

12

8K-12K

333

2

400-1000

stereo

32

360-1000

20

1000

1

1

2175-2350

3000-5000

1

8K-12K

2000

4000

430-805

2.5

2

>288

FLI/PMI

1000-2000

1.2x1.2

50

Image

(Moniteq)

FTVHSI

256

440-1150

67cm-'

0.8

15

IC

1996

90

IC

SI 986

(Kestrel)

24

400-1000

25

2.5,3.3,

Scanner

4

1500-2000

125

4.5

(GER)

29

2000-2500

17.2

6

8K-12.5K

750

GER-63

Channel

Continued on next page.

11

or

Sensor

(Agency)

Number

Spectral

BandwidthF

IFOV

FOV

of Bands

Range(nm)

YVHM(nm)

(mrad)

(deg)

HYDICE

206

400-2500

(NRL/ER1M)

ISM

(DESPA/IAS/OPS)

64

64

MAS

Data

Period of

Operation

7.6-14.9

0.5

8.94

IC

1994

800-1600

12.5

3.3x11.7

40

IC

S1991

1600-3200

25.0

50

547-14.5K.

31-517

2.5

85.92

IC

SI 992

MISI(RIT)

60

400-1000

10

2

±45

IC

S1996

MIV1S

20

433-833

20

2.0

70

IC

1993

(Daedalus)

8

1150-1550

50

64

2000-2500

10

8

90

90

2500-7000

25-70

0.5

1.3

IC

1989

6K-14.5K.

60-1400

ROSIS (MBB/

DLR/GKSS)

SFSI (CCRS)

SMIFTS

84

430-830

4-12

16

IC

SI 993

115

1200-2400

10.4

75

1000-5200

lOOcm"

(U. of Hawaii)

35

3200-5200

50cnr'

128

430-850

460-880

(Daedalus)

MUSIC

(Lockheed)

8

2K-12 7K

400-500

0.56

(<2400)

TRWIS-A

TRWIS-B

90

80

TRWIS-II

TRWIS-III

384

(32)

0.4

9.4

IC

SI 994

06

6.0

IC

SI 993

3.3

1.0

15

IC

1990

4.8

1.0

15

IC

1991

1500-2500

12

0.5/1.0

7.5/15

IC

1992

300-2500

5/6.25

0.9

15

IC

1995

1

(TRW)

IC

Hybrid VIFIS

(U. of

Dundee)

WIS-FDU

WIS-VNIR

WIS-SWIR

(Hughes SRBC)

Table

30

30

440-640

10-14

1

31.5

620-890

14-18

1

31.5

64

400-1030

1.36

129.265

400-1000

0.66

81+90

1000-2500

0.66

2. 2.

Summary of hyperspectral

IC

Test 1994

10&15

IC

Test 1992

19.1

IC

1995

12.0

IC

1995

airborne imaging spectrometers.

From Kramer, 1996.

B.

ULTRAVIOLET REMOTE SENSING

The Concept

1.

Passive remote sensing at ultraviolet wavelengths

spectral distribution of the solar irradiance at

in Figure 2.3.

ultraviolet

From

this

wavelengths

wavelengths.

diagram,

is

NUVIS was

it

relatively

is

ground

level.

is

quite dependent

This distribution

on the

is illustrated

easy to see that the solar irradiance available at

low compared

to

that

at

visible

and infrared

designed to operate in the daytime, using ambient scattered

UV radiation in the 300 to 400nm spectral band.

12

25

Energy curve

2

for

blackbody

at

6000° K

Solar irradiance curve outside atmosphere

Solar irradiance curve at sea level for a zenith angle of 0°

15

2

1.0

0.5

_UV/

200 400

600

2000

1600

800 1000

2600

3000

Wavelength (nm)

Figure

Spectral distribution of the solar irradiance (flux). Notice that the magnitude

2. 3.

of the available flux

absorption,

with

its

which

off rapidly

below 400nm. This decline

From

will be discussed later.

is

due, in part, to ozone

Finlayson-Pitts

& Pitts,

earth's atmosphere can be divided into a

own

approximate

unique characteristics.

behavior

number of atmospheric

layers each

Figure 2.4 illustrates these layers and provides the

of temperature

characteristic of the earth's

atmosphere

over

is

nonreactive major component gases (N 2

,

that

2,

these

it is

regions.

generally a

One

2.3.

13

distinguishing

homogeneous mixture of

noble gases) superimposed upon variable

concentrations of minor volatile and/or chemically reactive gases,

Table

1986.

Earth's Atmosphere and Ultraviolet Wavelengths

2.

The

falls

as

indicated

in

130

at

110

4>

u

VI

IB

o

"

E2-

_

*,

—

The rrri o s phe re

zL

90

" o

d

l.

o

*"*

.

-

-

S

-

-

A

Mesosph«r«

^"~^^^

>

V

<u

"

*i

—

50

-

Stratosphere

jS

30

e

Figure

Name

/

2. 4.

"

Oxygen / (Permanent)

Argon / (Permanent)

(Variable)

Carbon Dioxide

/

(Variable)

Z

layers.

(K)

From Lenoble,

T993.

% by volume

Formula

Molec. Mass

N

o

2

28.0134

78.084

2

31.9988

20.9476

Ar

39.948

0.934

H,0

18.0160

0-7

C0

44.00995

0.01-0.1

2

Ozone / (Variable)

Neon / (Permanent)

Helium / (Per. .anent)

Methane / (Permanent)

o,

47.9982

0-0.01

Ne

He

20.183

0.001818

4.0026

0.000524

16.04303

0.0002

Sulfur Dioxide

SO,

64.064

0-0.0001

Hj

2.01594

0.00005

46.0055

0-0 000002

Hydrogen

/

(Permanent)

Nitrogen Dioxide

Table

Since

CH

(Variable)

/

/

2. 3.

NUVIS

4

N0

(Variable)

-

300

Atmospheric

(type)

-

,r

250

Nitrogen/ (Permanent)

"

a;

Troposphere

Temperature

/

o

E

<a

3

^—_^_

_

200

Water Vapor

a.

o

E

\Tropopause

10

Constituent

o.

:

Atmospheric constituents. From Durkee, 1999.

currently operates at ground level, the properties of ultraviolet

radiation in the lower troposphere are of paramount interest.

radiation can reach the troposphere,

it

must

14

first

Before any solar ultraviolet

pass through the various overlying

atmospheric

layers.

Far ultraviolet wavelengths are strongly absorbed at higher altitudes

(above 100km) by molecular and atomic oxygen and nitrogen. More importantly, a great

majority of

UV absorption is caused by oxygen in the mesosphere and upper stratosphere,

principally in the form of ozone.

NUVIS

(~300nm). Figure

2.5

These absorbers are active

summarizes these

ii

in the spectral

bandpass of

effects.

—

1

l

i

i

150

E

o

100

-

Z>

»-

50

<

i

i

50

100

150

WAVELENGTH

Figure

2. 5.

Depth of penetration of solar

attenuation of Me.

C.

II

i

i

1

250

200

300

(nm)

radiation.

Altitudes correspond to an

From Lenoble,

1993.

SULFUR DIOXIDE

1.

An Atmospheric

Pollutant

Absorption of ultraviolet radiation by atmospheric gases

cases of nitrogen, oxygen and ozone alone.

atmosphere that absorb

at

these shorter

not limited to the

There are a number of trace gases

(UV) wavelengths.

15

is

in the

Nitrogen dioxide (NO2)

and sulfur dioxide (S0 2 ) are two such examples. For the purpose of

work, only the

this

trace gas, sulfur dioxide, will be studied.

Sulfur

dioxide,

suffocating odor.

in the

It is

Figure

2.6,

extremely

is

a

colorless

fuels

major atmospheric pollutant. This trace gas

cycle illustrated in Figure 2.7.

pollutant

emitted by

fuel

and

is

in the smelting

characteristic

tract.

It is

formed

of sulfide ores and

only a small part of the

This cycle not only demonstrates that

much

S0

2

is

is

emitted as

A^

*

larger sulfur

is

a primary

2. 6.

S0 2

(Finlayson-Pitts and Pitts, 1986).

Sulfur (S)

Oxygen

(O)

Sulfur dioxide molecule

(SO : )

-Gother

PMs

]

~ C OS

J

^-

f

(

(

H 2 S }—I—f SQ 2 }— HSQ3 }— [ SQ 3

[

)

[n 2 SQ4 ]

(

JOlSj

t *

biogenic

Figure

volcanic

2. 7.

a

combustion (from coal burning power plants) but also

demostrates that most volcanic sulfur

Figure

which has a

eyes and respiratory

irritating to the

combustion of sulfur-containing

gas,

anthropogenic

Sulfur cycle demonstrating volcanic and

16

man-made sources of S0 2

.

Monitoring of sulfur dioxide has become a global concern as data are routinely

from a number of

collected

Monitoring

activity,

S0

SO

2

:

is

different

sensors

to

monitor

of interest for a number of reasons.

see Figure 2.8

ground

worldwide.

For years now, the Correlating Spectrometer (COSPEC), a non-

).

Such monitoring

is

to

monitor effluent

warn of a

rise in

2. 8.

COSPEC

instrument

at

17

2

SO, concentrations

level.

Figure

S0

important, especially in densely populated

regions, to aid in predicting volcanic activity and to

at

levels

In regions of high volcanic

imaging spectrometer, has been employed by vulcanologists

(

:

monitoring can provide yet another valuable tool to assist in the study of

volcanic activity.

levels

SO

a volcanic

site.

From USGS,

1999.

The Environmental Protection Agency (EPA) has long been

A

monitoring anthropogenic (man-made) sources of sulfur dioxide.

been placed on coal burning power

plants.

The

EPA

has established

interested

primary focus has

strict

guidelines for

allowable types and levels of emissions that these plants can produce.

effluent levels

the

power

from these sources can be accomplished

plant's

either

by sensors

stacks themselves (in situ measurements) or

in

Monitoring

installed within

by remote sensing

techniques.

With these

factors in mind,

NUVIS

designers set out to build an instrument

capable of detecting SO, emissions from both natural and

S0

Since typical

power plants

to

2

ppm

An

S0

2

effluent sources.

in the case

of regulated

NUVIS would

hundreds or even thousands of ppm for volcanic vents,

required to detect

2.

concentrations range from only tens of

man-made

be

over a very wide range of absorption column densities.

Ultraviolet

Absorber

Sulfur dioxide was chosen for study because the gas exhibits a strong absorption

signature in the near-ultraviolet (200-400nm).

Although

S0

2

absorbs to some extent over the entire 240 to

the region longward of

atmosphere.

This signature

300nm

This region

is

is

(see Figure 2.3).

A

Figure 2.9.

320nm wavelength

of most interest for measuring

S0

2

range,

concentrations in the

advantageous because the illumination source for doing

absorption spectroscopy in the field

level, this scattered radiation

is illustrated in

is

Rayleigh scattered solar

diminishes sharply

further advantage

is

at

UV

At ground

wavelengths shorter than about

that if in this region,

18

radiation.

S0

2

300nm

spectra can be

readily distinguished

from the spectra of other absorbers (see Figure

chose to concentrate on laboratory and

350

nm

wavelength range.

—

200

field

measurements of

A

Figure

2. 9.

S0 2

2.10).

Hence,

we

spectra in the 300 to

/nm

Gas phase absorption spectrum of S0 2

.

The

extinction coefficient sis

proportional to the absorptivity coefficient presented in section ID. 2.

From

Atkins, 1990.

PHOTOABSORPTION CROSS SECTIONS

T

Yoshino + Freemon O.

1

I

95K

SOLSTICE (scoied)

lO"

,-18

10"

lO"

lO"

O (Amoruso

et ol)

_i

i

i_

_i

240

Figure

2. 10.

i

i_

_i

260

i

L

j

280

Wavelength (nm)

»

30O

Photoabsorption cross sections of atmospheric

cross section data obtained from the Solar Stellar Irradiance

(SOLSTICE)

is

also displayed.

19

From

320

UV absorbers.

340

Solar

UV

Comparison Experiment

Strickland, 1999.

ABSORPTION SPECTROSCOPY

D.

Introduction

1.

Absorption spectroscopy

radiation from a continuum

is

the study of the wavelength-dependent absorption of

some chemical

source by

species of interest.

laboratory, this technique usually involves working with a calibrated

source.

In

NUVIS

Rayleigh scattered

The

UV

5800

proportional to

effect of these

source in the

I

striking

the atmosphere has

is

light

the ambient

approximately the spectral

blackbody (see Figure

4

where X denotes wavelength (Lenoble, 1993).

,

two natural phenomena

300nm wavelength

also utilizes this

background continuum source

K

A,

continuum

solar radiation, as discussed above.

solar irradiance

distribution of a

is

field applications, the

In the

region.

to

is

The

2.3).

The Raleigh

scattering cross section

The combined

provide a useful background continuum

COSPEC

instrument previously mentioned

continuum radiation source.

Understanding

how

molecular absorption spectroscopy

is

used to

measure

molecular concentrations requires a basic knowledge of the energetics of the molecules of

interest.

The

total

energy

E of a molecule

arises

from four contributions, represented by

the following equation:

E=E

E

rot

is

rot

+ E vib + E elec + E trans

the rotational energy of the free molecule about

its

(

center of mass.

E vib

is

2" 1

the

vibrational energy of the constituent atoms, typically in one of the molecule's vibrational

normal modes.

E

elec

is

the electronic energy analogous to that of the electronic energy of

20

atoms.

isolated

E

molecule's overall translational

the

is

trans

kinetic

energy.

In

spectroscopic applications, the rotational, vibrational and electronic energy levels are of

interest, since

energy

is

quantized for these

modes of free atoms and molecules. Because

of the bond energies, masses and moments of inertia of small molecules, transitions

between

rotational

states

are usually observed at infrared

Vibrational transitions are typically observed,

at

Electronic transitions generally occur at visible and

visible

and longer wavelengths.

and infrared wavelengths.

UV wavelengths.

(Lenoble, 1993)

Figure 2.11 provides a generalized representation of these energy levels for a

simple molecule.

characteristic

Like

many

UV absorption

Figure 2.11.

other molecules, gaseous

S0

2

exhibits

its

own

unique

spectrum. If an incident radiation field induces photons

Molecular energy curves for two electronic

states.

These curves

demonstrate the relationship between vibrational, rotational and electronic levels.

(This general depiction

is

not to scale.)

21

From Eisberg and

Resnick, 1985.

whose energies correspond

the molecule

may

to the difference

absorb a photon and

between two energy

jump

to a higher energy level.

wavelength-dependent absorption, or absorption spectrum, that

quantum

is

The

result is a

characteristic

of the

structure of the absorbing species.

Terminology

2.

Transmittance

is

the term used to describe the fraction of the energy of the

incident radiation that passes through an absorbing

beam of

levels of the molecule,

parallel radiation before

medium having

is

after

it

Figure 2.12

illustrates a

has passed through a layer of absorbing

a thickness of d and a concentration of c of an absorbing species.

to the interactions

intensity I

and

medium.

between the incident photons and the absorbing

attenuated to an exiting intensity / (Skoog, 1985).

particles,

Due

an incident

The transmittance

T

of

Absorbing medium

of concentration:

Path length:

Figure

2. 12.

*"

d

A parallel beam of incident radiation before and after

it

has passed through

a layer of absorbing medium.

the

medium

is

thus defined as the ratio

T = IIIn

22

(2.2)

A

Absorbance,

is

defined as

A=-log(T)=log(I

If the likelihood

(2.3)

of multiple absorptions and reemissions along the path

linear relationship

by Beer's

/I).

is

small, there

a

between absorbance and concentration of an absorbing species given

Law

A=a(X)dc

(Skoog, 1985).

The function a(X)

Law, the attenuation of a

is

(2.4)

called the absorptivity coefficient.

signal can be given

From

a is the absorption cross

Absorption

is

(2.5)

section and TV is the molecular

a quantity that differs from absorbance.

of the Einstein probability coefficient,

Bn

,

Beer's

by

I=I exp(-crNd),

where

is

but in practice,

number

It

density.

can be described in terms

it is

more often described

in

terms of an absorption coefficient, k(v). This parameter describes the fractional decrease

in flux density (intensity) at frequency

v per unit path length through the absorbing

medium:

-5I(v)=I(v) k(v) Sx,

where I(v)

is

incident

upon the layer of thickness

Sx.

(2.6)

Assuming

a

homogeneous

layer of

thickness d, integration yields

Id(v)=I (v)exp(-k(v)d),

23

(2.7)

where k(v) d

is

known

as the frequency-dependent optical depth, z(v).

increasing optical depth on an isolated absorption line profile

(Thome

et al.,

From

The

is illustrated in

effect

of

Figure 2.13.

1999)

a practical standpoint,

it

is

the effective area of an absorption line that gives

the most useful measure of spectral absorption that

absorption lines (curves) of Figure 2.13,

may be

is

taking place.

The areas under the

defined by the following equation,

"o

Figure

2. 13.

Hypothetical absorption line profiles demonstrating the effect that an

increase in optical depth has on a line shape. Lines

increasing optical depths, t(v)

which

is

.

a, b,

and c represent shapes

From Thorne

et. al.,

for

1999.

normalized to the incident flux density,

W=L

e

(l-exp(-k(v)j)dv.

24

(2.8)

Equation 2.8 equates well to transmittance through the following relation,

W = f Jl-T(v)]dv,

(2.9)

n

where

W

is

called the line's equivalent width, and T(v)

transmittance from equation 2.2.

spectral line

the

where the shaded area

continuum baseline,

Figure

Figure 2.14

2. 14.

is

the frequency dependent

further depicts the equivalent

width of

equivalent to the area between the line profile and

1(0).

Equivalent width measurement. Note that the shaded area

area between the line profile and continuum baseline, 1(0).

It

is

is

From Thorne

equal to the

et. al.,

1999.

should be noted that the actual absorption of an isolated spectral line can be

spread over a broad range of frequencies by natural, Doppler and pressure broadening

(Thorne

et al.,

1999).

Furthermore, the relation between the absorbance and I(v)

logarithmic, not linear, so equation 2.9 does not hold true for

individual equivalent line widths

is

all

cases.

thus a more detailed process than

overall trend of the absorption cross section of Equation 2.5.

25

However,

it

is

Measuring

measuring the

can be shown

that linearity applies as long as the absorbing line is not highly saturated

profile's center

utilized

widths

equivalent

using

nonsaturated

This

lines.

accomplished without correcting for any line shape effects and assumed

2.9

was applicable

see Thorne

et. al,

*

l(v)

at the

Therefore, for the purposes of this thesis research, Equation 2.9 was

).

calculating

in

(

to all equivalent width

that

was

Equation

measurements. For a more detailed approach,

1999.

The Curve of Growth

3.

In spectrochemical analysis by

means of absorption spectroscopy,

it

has become

standard practice to quantify the effects of an absorbing species abundance on the profile

of an absorption

line as

growth for a spectral

an empirical graph called a curve of growth.

line describes the

concentration of the absorbing species.

illustrated in Figure 2. 15.

known absorber

1-5

behavior of the equivalent width as a function of

It

normally takes the form of a log-log plot as

In practice, the equivalent widths are

concentrations in the laboratory.

measured

Figure

2. 15.

1.5

2.0

3.0

Typical curve of growth. (Also

curve.)

26

for a series

The equivalent width of lines found

r_

1.0

The curve of

known

5.0

as a calibration

of

in

field data

may be

subsequently compared to the curve of growth, which then yields the

molecular abundance of the

field sample.

Remarkably, curve of growth analysis has been found

to different line profile shapes

(Thome

et. al.,

1999). Hence,

a wide variety of spectroscopic instruments and conditions.

line shapes,

Figure

Gaussian and Lorentzian, are illustrated

2. 16.

Gaussian and Lorentzian

profiles.

From Thorn

in

to

it is

be relatively insensitive

of general

Two commonly

Figure

2. 16.

utility

across

encountered

This study will only

Areas under each curve are the same.

et.al.,

1999.

involve calculations based on Gaussian line profiles that

may be

represented by curves

having the generalized form:

F(x)=A

exp{-[(x-

27

AtfAf/21

(2.

10)

where F(x)

is

the profile,

A

is

the height of the Gaussian,

and A 2 is the width of the Gaussian. Equation

calibration of the

NUVIS

2.

A

}

is

the center of the Gaussian

10 will be utilized in the curve of growth

instrument and in the analysis of field data presented in

Chapters IV and V.

28

NUVIS

III.

BACKGROUND

A.

NUVIS was

NPS

designed, developed and constructed by former

Professor Dr. David Cleary and students,

MacMannis (MacMannis,

1997).

Todd Hooks (Hooks, 1997) and Andrew

the

is

It

Associate

latest

spectroscopic instruments developed by Dr. Cleary and

a

in

is

succession

of ultraviolet

the first to incorporate spectral

imaging capabilities (Cleary, 1998). For a more detailed account of some of this

work done on

UV instruments such as MUSTANG and DUUVIS, see Johnson,

In principle, the

NUVIS

instrument of today

developed by Hooks and MacMannis.

is

identical to the instrument first

Designed and

.

1996.

HARDWARE

OPTICAL, OPTOMECHANICAL AND ELECTRONIC

B.

earlier

built

to

test

the

utility

hyperspectral imaging at ultraviolet wavelengths, the instrument's optical design

classic

Rowland

scanner.

As

it

circle spectrograph

appears in Figure 3.1,

and are summarized

its

imaging design follows

NUVIS

is

in

The instrument

wavelengths.

of a push broom

a portable instrument capable of field

Table

3.1.

itself is

comprised of nine basic components, which are

Figure 3.2. Light enters the instrument through a

UV

that

a

Instrumental parameters remain as originally detailed by Dr. Cleary

operation with ease.

in

and

is

of

It

filter

window, designed

then encounters a scanning mirror assembly.

comprised of three sub-components:

1) the

mirror

29

itself,

2) a stepper

illustrated

to pass

only

This assembly

motor

driver,

is

which

mm M'Ssrtm

Figure 3.1.

NUVIS

instrument.

NUVIS PARAMETERS

Optical Design

Rowland

Imaging Design

Push Broom Scanner

Spectral

Response

300

Spectral Resolution

Full Field

to

Circle Spectrograph

375nm

0.3 run

of View

20° x 6° (350mrad x lOOmrad)

Bands (Spexels)

~ lmrad

640

Positions

480

Lines (available)

351

Mode of Operation/

SNAP/ 640x480x1 data array

SCAN/ image cube (640 x 480

Angular Resolution

DATA

output

Table

3.1.

NUVIS

>ZZZ

parameters.

30

From

x

ZZZ)

Cleary, 1998.

Figure 3.2.

NUVIS

components. Top: Schematic of NUVIS:

scanning mirror assembly, 3) baffles, 4) telescope mirror, 5)

grating, 7)

image

intensifier, 8)

CCD camera,

1) filter

slit,

window,

and 9) cable connectors.

Bottom: Photo of NUVIS instrument components, (with cover removed)

31

2)

6) diffraction

and 3) the

rotates the mirror,

Light reflected by the scanning mirror strikes a

the angular position of the mirror.

which focuses the beam onto the entrance

telescope mirror,

Rowland

optimized for

image

From

circle.

The

grating.

which provides feedback information about

shaft encoder,

the

slit,

image

intensifier.

operation, optically amplifies the signal

intensifier" s

output

is

which

is

C.

intensifier,

The

.

lum by 13um

pixels.

NTSC

lines.

1

30 frames per second

is

(fps) analog

video

limited to an eight bit grayscale and a

(Hooks, 1997)

THE COMPUTER, DATA ACQUISITION AND CONTROL SYSTEMS

The next major component of

The 233

MHz PENTIUM

Pro

PC

includes

equipped with standard 3.5 floppy and

256Mb Ram and

CD-ROM

is

an

NUVIS

data

supporting peripherals.

a 3.0

GB

drives as well as a

is

the

is

1

hard drive.

It is

GB

JAZ

internal

processed into digital form by a

PC

grabber interface card. Interfaces to the stepping motor controller and

shaft position encoder are provided

monitor

system

CPU, monitor and

The video output from NUVIS's camera

IMAQ-1408 frame

NUVIS

the total

acquisition and control computer, including the

drive.

The image

(CCD)

conventional

by 480

on the

coupled to a Pulnix TM-745e charge coupled device

through a standard RS-170 interface and

resolution of 640

located

by a factor of nearly 10 6

video camera. The camera has 768 by 494 pixel resolution with

The camera output

is

light travels to a field-flattened spherical diffraction

diffracted light then goes to an

UV

slit,

NEC

Multisync

LCD

by DAC-02 and PIO-24ISA/EISA

15 inch flat screen display.

external views of the computer system.

32

cards.

Figure 3.3

The

illustrates

Lh'U, Monitor, Keyboard, ana mouse. Mote

that all

still

components are

tsacK panel 01

c^u

witn network nuo

DAC-02 PIO-24ISA/EISA &

PC IMAQ-1408 frame grabber cards

easily operated while

attached.

inside the customized shipping case.

,

the

displayed from the bottom up.

Figure 3.3.

NUVIS

control computer.

Control of the scanning mirror drive mirror drive-is provided by the

stepper motor controller that

NUVIS

system deployed

is illustrated in

in the field,

involved with on-site operations.

A

Figure 3.4.

demonstrating

detailed account

required for field operation can be found in the

Figure 3.4.

Max-410

33

NUVIS

MAX-410

Figure 3.5 shows the complete

some of

the logistics and setups

of suggested system components

field checklist

stepper controller.

of Appendix A.

Left:

Volcanic Site

Figure 3.5.

NUVIS

Right:

system components and

34

Power Plant

Site

field logistics.

DATA ACQUISITION, CONTROL AND DATA DISPLAY SOFTWARE

D.

As NUVIS was being develpoed,

for instrument control, data acquisition

several key software routines

and data

display.

were developed

Various modules of

this

software were written in Microsoft Visual Basic and Interactive Data Language (IDL),

which

is

a Research Systems, Inc. (RSI) product.

in the following references:

in

Appendix

Hooks, 1997; Aitken, 1997; and Using IDL, 1997 as well as

B.

In essence, the acquisition of spectral

algorithmic loop.

interest falls

light

may be found

Specifics of the software

The scanning mirror

is

on the instrument's entrance

from the

slit

across the camera.

NUVIS

is

a simple

rotated so that one edge of the target scene of

slit.

The

diffraction grating then disperses the

Because the Rowland

stigmatic (image-preserving), the resultant

along the dispersion axis as a function of

image data with

2D image

ID scene

circle spectrometer is

consists of spectral information

height along the orthogonal axis.

In

other words, an image frame consists of a set of spectra for each scene pixel focused on

the entrance

strip

is

slit.

Each of these scene

pixels,

however, belongs to only a narrow vertical

of the whole target scene. So, the camera frame

is

stored, then the scanning mirror

rotated slightly to position the next vertical strip of the scene onto the exit

frame acquisition procedure

is

repeated.

This sequence of operation

is

slit,

and the

repeated until

data from the entire scene has been acquired. Subsequent off-line processing can then be

used to generate a hyperspectral cube data

set

35

and to display the data

in various formats.

Sample output from a

This particular set

is

Two

deployment

is

provided in Figures 3.6 through 3.8.

drawn from data taken of an

The image scene includes

some

field

industrial coal burning

three operating smokestacks.

level of sulfur dioxide emissions, as well as a

of the stacks have modern to contain

third (dirty) stack emits

S0

2

at levels

S0 2

(Further detail of this field collection

number of other

be found

The black and white image of Figure

effluent products.

scrubbers that reduce emission levels.

on the order of ten times the

may

plant.

All three stacks are producing

This particular collection was conducted on

scrubbed stacks.

power

3.6

in

is

site at

ppm

The

values of the

a range of 1.5 km.

Chapter V.)

produced directly from the sensor's

recorded digital signals through a transpose, rotation and resizing of the data array.

Although the stacks are quite

visible, this

format does not provide enough information to

allow for the isolation and identification of SO, signatures in the data.

Figure 3.6.

NUVIS

IDL

black and white image.

false-color

This image was produced by the

procedure, Bw_roughimage.pro.

36

A

From Cleary,1998.

image can also be created to survey the

This was done for the power plant work,

data.

using color assignments:

Red

:

350-375nm,

Green: 325-350nm,

Blue

This approach results

in the false

:

300-325nm.

color image of Figure 3.7, in which potential regions of

sulfur dioxide appear yellow in color.

Figure 3.7.

NUVIS

false-color image.

"color_image.pro". Regions of

Field operation of

data

in

NUVIS

S0 2

This

is

appear yellow

necessitates a

to

allow

this.

modeled absorption cross section of

illustrated in Figure 3.8.

It

in color.

means of obtaining quick looks

order to ascertain whether or not the instrument

procedure was developed

IDL procedure,

From Cleary, 1998.

a product of the

is

functioning properly.

performs a least-squares

SCX

fitting

Output displays from

this

37

An IDL

of the data to a

procedure are

This corresponds to 200 different spatial (altitude)

(wavelength) slices of the hyperspectral image cube.

at the

vs. spectral

For presentation purposes, data

midway through

processing has been interrupted

windows presented

the output

of Figures 3.6 and

that

actively displayed

presented and

is

3.7.

from from

the scene at line

to the data analyst.

Window

During the execution of

right to

left.

A

1

number 99

shows a display similar

this procedure,

full false-color

to illustrate

processing

image of the scene

to

is

is first

then actively processed, scan by scan (line by line) within the window.

The display labeled

as

Window

2 represents the raw data or digital

number

that is

recorded for each individual pixel in the spatial (altitude) vs. spectral (wavelength) slice

corresponding to line number 99.

(plane),

The raw data displayed on

corresponds to the line dividing the color and black and white images in the

the

This line marks the point

left.

Within

display.

opposite

is

Window

2, the

at

This raw display

during system operation. Feedback

of the same data

scan

sliced to produce such a

The

is

is

at a

time

the only real-time feedback provided

provided through the

later in analysis

Thus, Figure 3.8 also

process

presented to the user

is

NUVIS

displayed by the Visual Basic instrument control program

and two.

window on

darker pixels represent lower levels of detection.

2 also parallels the actual raw data display that

during instrument operation.

is

right,

true for the brighter pixels.

Window

which

which the image cube was

the

is

operational

NUVIS.EXE.

presented in the lower

illustrates the representative

window,

A view

windows one

output at the 150"' vertical

line.

In the field, the data acquisition

and control

PC

can be networked to another

computer, typically a laptop PC. The various IDL data analysis and display procedures

38

can then be run on the laptop while the host

instrument.

PC

is

otherwise occupied with running the

This provides a quasi- real- time means of verifying

NUVIS's

operation

in the

field.

Window

1

Window

I

Figure 3.8.

for the

99

th

SO^ algorithm

vertical line scan

"assay_image.pro."

the 150

th

output.

Upper Windows demonstrate output

of the image scene during execution of the algorithm,

Lower windows demonstrate processing some

scan position.

In

Y)

displays

each case, altitude

direction.

From

39

is

displayed

Cleary, 1998.

time later at

in the vertical (spatial-

THIS PAGE INTENTIONALLY LEFT

40

BLANK

LABORATORY CALIBRATIONS OF NUVIS

IV.

PURPOSE

A.

In order for

NUVIS

to

be applied to

field

measurements of

of calibrations must be performed, either beforehand or on

First,

site

S0

2

plumes, two types

during field deployment.

an approximate spectral wavelength scale must be established, so that spectral

signatures of interest can be reliably and reproducibly identified.

Second, the relevant

curves of growth for the signatures must be available so that the instrument can be

employed

for reliable

and credible spectrochemical abundance measurements.

This

chapter summarizes the laboratory calibrations that were performed in these contexts.

The next chapter discusses applications of the

B.

calibrations to actual field data.

WAVELENGTH CALIBRATION

Before continuing onto generation of the curves of growth,

discuss the association of instrument spectral samples (sometimes

wavelength.

it

is

necessary to

known

as spexels) with

This phase of calibration was conducted by Dr. Cleary, just prior to

involvement with the

NUVIS

project.

first

my

Results of the wavelength calibration were saved

MB data file entitled wl_cal.dat.

in a 1.2

The

source.

calibration

was accomplished using a standard spectroscopic emission

The source used was a platinum

(Pt)

hollow cathode lamp, whose characterisitics

and calibration are traceable to the National

(NIST).

This source was chosen because

emissions in the 300 to

line

400nm wavelength

41

Institute

it

of Standards and Technology

exhibited a

range.

number of

useful spectral

This particular lamp

is

used in

conjunction with a Harrison 6522

set at

400

volts

15mA. Nine

DC

power supply. For operation, the supply

and 0mA. The current

is

is initially

gradually increased to the operational level of

Pt emission lines were identified and utilized in the calibration.

These lines

are listed in Table 4.1.

Wavelength

Line

Table 4.1

.

Line

Wavelength

Wavelength

Line

504.26

337.82

359.36

506.47

340.81

369.42

54.54

352.05

372.71

Nine platinum emission

lines

chosen for the wavelength calibration.

FromCleary, 1998.

As with any

diffraction grating instrument, the grating equation applies. (For

further explanation see both

MacMannis, 1997 and Hecht, 1998.)

This means that the

actual wavelength of a spectral feature should be a sinusoidal function of

(spectral sample) in the

measured data frame.

It

the sinusoid could be adequately approximated

range. This behavior

is

summarized

in

its

position

was found experimentally, however,

that

across the 300 to 400

nm

by a

linear

fit

Equation 4.1

Y=(0.118)x + 300.775,

where x

is

the spexel number,

spexe! and

Y

is

m the spectral dispersion,

(4.1)

b the wavelength of the '"zeroth"

the corresponding wavelength in nanometers.

illustrated in Figure 4.1.

This calibration was applied in

all

This behavior

instances

necessary to associate wavelength to a corresponding spectral sample.

42

where

It

it

is

also

became

also provided a

simple means for calibrating the wavelength scales of spectra measured with

NUVIS,

provided that the optomechanical configuration of the instrument remained stable.

Wavelength Calibration

200

300

600

4C

Spectral Sam pie

Figure 4. 1

.

Wavelength calibration associating band number/spexel

to

wavelength.

C.

EXPERIMENTAL OVERVIEW

As

stated earlier, only absorption lines existing longwards

for laboratory

measurement because absorption

shorter wavelengths

were

lines that

of 305nm were chosen

appeared in the field data at

either saturated or subject to severe noise because

decreasing background illumination.

of rapidly

Figure 4.2, vividly demonstrates the relatively

closely spaced group of absorption lines that were targeted for calibration.

In the end,

four absorption lines were identified as suitable for equivalent width measurements in the

calibration.

The

spectral

sample numbers and wavelengths corresponding to the centers

of each of these absorption lines are

listed in

Table 4.2. Because

43

NUVIS was

expected to

operate over a wide range of column densities, the decision was

on the instrument's lower

made

to first concentrate

sensitivity limits.

Measured S02 Absorption Lines

c

.2

0.8

%

0.6

-

X>

<

«

0.4

Is

13

0.2

-*

200

100

400

300

Spectral

500

600

Sample Number

Figure 4.2. Example of SCVs closely spaced absorption

plot,

lower spectral sample numbers equate to higher

and higher numbers equate

Measured

700

to

In this

lines.

UV wavelengths

lower ones. See Figure

4. 1.

1

2

3

4

535

554

572

590

313

310.9

308.8

306.5

Absorption Line

#

Spectral Sample

Number

Center

Wavelength

(ran)

Table

D.

4.2.

Absorption lines targeted for measurement.

LABORATORY MEASUREMENTS OF SO,

There are two contraints on the gas concentrations

calibration studies.

First,

that are useful for laboratory

the experimental noise floor sets a practical lower limit to the

instrument's sensitivity. That

is,

weak

spectral features that are buried in the noise

44

must

simply go unmeasured.

This translates into a lower useful limit to

used in the laboratory. Second, as discussed

earlier,

S0

2

concentrations

highly saturated spectral features do

not provide reliable measurements of spectrochemical abundance, and so should be

This sets a practical upper limit on laboratory gas concentrations.

avoided.

S0 column

weighing such considerations,

six

summarized

4.3.

They

are

in

Table

abundances were decided upon for study.

2

Column abundance

Sample

(oc

concentration)

[(#molecules/m

Table 4.3. The six

After

5.33

3A

3A

7.48

4B

4B

2.25 x 10

5.61 x 10

4.24

)

m)]

xlO 21

1A

2B

1.07

3

21

xlO 21

xlO 22

22

xlO 22

test cell concentrations utilized in

generating the curves of

growth.

Gas Test

1.

S0 was

2

UV

placed in transparent test cells of various lengths and illuminated with

continuum radiation

1.55 meter long

Cells

PVC

to

produce laboratory spectra. The

tube with quartz

windows

first test cell

(see Figure 4.3).

employed was a

Once evacuated with a

conventional fore pump, the cylinder could be filled through a pressure regulator with

0.11

%

sulfur dioxide in an inert dilution gas

pressure gage

Figure 4.4.

(

to

760

mm Hg

)

that

(N 2 ).

were both

For various reasons, the 1.55

m

45

The valve manifold and Matheson

utilized in this process are illustrated in

cell

proved

to

be cumbersome, prone to

leaks,

and too long for producing low column abundances of

test cell

S0

2

was designed.

Figure 4.8. Pressure gage and valve manifold.

Figure 4.4.

1

.55

m gas test cell #1