ME422 Problem 1: FEM Homework #7 Distributed: January 24, 2011

advertisement

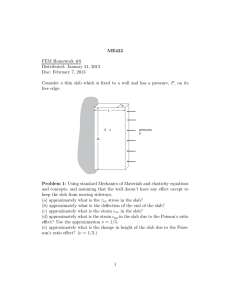

ME422 FEM Homework #7 Distributed: January 24, 2011 Due: January 31, 2011 Problem 1: Consider quenching of a steel slab. Initially, the slab is at a temperature T0 . It is suddenly plunged into oil at Toil . 20W 20W 2W k ρ cp ho Toil T0 W = 43 w/mK = 7801 kg/m3 = 473 J/kgK = 2000 W/m2 K = 20 C = 850 C = 0.01 m These are realistic properties for steel, and fairly reasonable values for the convection coefficient for quenching. Based on your engineering intuition, is the centerline temperature more likely to drop to about 450 C in (a) 1 day (b) 1 minute or (c) 1 microsecond? Describe any experiences you have had that back up your answer. (Just give me a few lines here– you don’t have to write a long description. Pretend you are trying to explain your reasoning to your boss.) 1 Problem 2: Now do this problem in ANSYS Workbench. Because the slab has three planes of symmetry, we can model just one-eighth of the entire slab. (This saves a whole lot of elements!) (a) For your one-eighth model, you should have three faces with convection and three faces that are insulated. Sketch the one-eighth model and show the boundary conditions on your sketch. (b) Run the one-eighth model in Workbench. • You will need to move the “Transient Thermal” application to your toolbox. I believe that you will find that most of the changes for transient analysis are fairly intuitive. • Be sure that you refine the mesh enough to get at least three or four elements through the narrow dimension of the slab. • Rather than using the default values for the time stepping, use a total time of 10 seconds and a time step size of 0.1 seconds. Do this in “Analysis Settings”: – Set “Auto Time Stepping” to Off. – Set “Number of Steps” to 1. – Set “Current Step Number” to 1. – Set “Step End Time” to 10s. – Choose “Define by”, “Substeps” – Set “Number of Substeps” to 100 – Leave “Time Integration” “On” Now solve it. • Workbench can then be used to make some really nice animations of the temperature profiles. Print the plot of the temperature contours at time=1 second so I’ll know that you were able to get this to run. Make sure that the results you get are reasonable, given your answer to Problem 1. (c) Now click on “Solution Information”, which gives you a really old-fashioned looking printout. Click in the printout window and type control-F, use the search function to find the word “THETA” in the document. What value of 2 θ was used with the θ method for the time integration of this problem inside ANSYS? Problem 3: If we want to make a simplified model of the slab, we can just model what happens along the midline (as shown in the sketch below.) Use 2 linear finite elements along with Euler backward time integration to solve for the temperatures in the slab as a function of time. W slab convection (oil) ho T2 T3 T1 T oil (a) Find the 3×3 stiffness matrix for the problem. Don’t forget the convection term. (b) Find the 3×3 mass matrix. (c) Find the forcing vector (3 terms). (d) What is θ for Euler Backward integration? (e) For Euler Backward integration, we can write K̂T|n = F̂ Find K̂ and F̂ for this problem. (f) Solve for T as a function of time and plot T1 (t), T2 (t), and T3 (t). Run oil your calculation until T1 ≤ T0 +T . 2 (g) Does your answer seem reasonable compared to your estimate from Problem 1, and with your Workbench solution from Problem 2? Fix something if it doesn’t seem correct. 3