Document 11705120

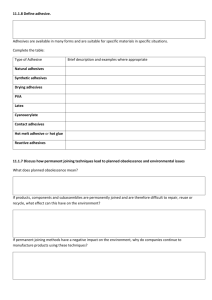

advertisement