Agomet® P 970, english

advertisement

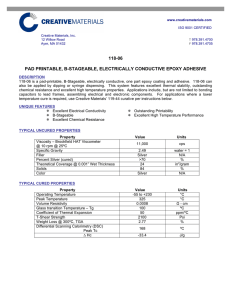

Adhesives and Tooling Structural Adhesives Agomet® P 970 One component, heat curable gap filling epoxy Properties Agomet P 970 is a modified hot curing one component epoxy adhesive for bonding of metals and temperature resistant rigid plastics. Bonds produced with Agomet P 970 feature excellent strengths and long-time durability. Being hard and tough, Agomet P 970 withstands alternating stress particularly well. Agomet P 970 comes ready-to-use. The adhesive fills gaps up to a width of approximately 5 mm. It cures under heat, generated for example in a circulating hot air furnace, by an infrared heater or by induction. Agomet P 970 does not react at room temperature. Bondable materials Metals such as aluminium, stainless steel, iron, galvanised steel, copper, brass, zinc, ferrites. Plastics such as phenolic, melamine or urea formaldehyde resins and unsaturated polyester parts. Viscosity approximately 165 Pa.s Specific gravity Approximately 1.45 Processing Surface Preparation To optimise bonding results, all surfaces of the parts to be joined should be free of loose impurities such as dust, oxides, grease, release agents or plasticizers. A simple wipe with a solvent such as ethyl acetate or - for plastics - alcohol is sufficient. Normal residues of rolling or drawing oil are compatible with Agomet P 970 and need not be removed. Bonding Apply Agomet P 970 to one of the two surfaces to be bonded, then join the parts and fix in place under contact pressure. Cure the bonds with heat, ranging from 140 °C for a time of 60 minutes up to 200 °C (highest advisable temperature) for only 20 minutes. Agomet P 970 is very convenient to process and dispense: The adhesive comes in cartridges which fit into any standard "silicone gun". Under a pressure of 5 bar, about 50 - 65 g adhesive/minute are dispensed through the 3 mm nozzle tip. A 3 mm ∅ bead of adhesive will flow only 2 mm at 23°C/30 minutes and just 4 mm at 200 °C/60 minutes. Agomet P 970 meets the automotive industry's requirements for bonding of body parts: - Inductive pre-gelling = heat-up from 23° to 160°C within 5 seconds, hold at 160°C for 9 seconds. - The pre-gelled adhesive does not wash out in pretreatment baths or during electro-dipcoating - Welding poses no problem, it does not stimulate any development of corrosion. - The bond absorbs almost no water and hardly degasses while curing. Publication Number A 486 a GB Provisional Page 1 of 2 Bonding Performance Tensile Shear Strength Aluminium/Bondur F 44 (AlCuMg2pl) Steel ST 37 Steel V4A Steel, hot galvanized (only degreased) Copper Brass Test specimen 100 x 25 x 1.6 mm, bonded area: 300 mm², bond line thickness: 0.2 mm curing conditions: 25 minutes/170°C tensile shear test according to DIN 53 283 Surface preparation: degreased, roughened. Dependence of tensile shear strength on test temperature Aluminium standard test specimen 100 x 25 x 1.6 mm AlCuMg2pl (typical mean values) 23 N/mm² 22 N/mm² 28 N/mm² 20 N/mm² 18 N/mm² 20 N/mm² Tensile Shear Strength [N/mm²] 30 25 20 15 10 5 0 -50 -30 -10 10 30 50 70 90 110 130 150 Test Temperature [°C] Advice Shelf Life Please see labels: a minimum of 4 months in the original unopened container. Handling Precautions Caution Vantico products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed. The uncured materials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and measures should be taken to prevent the uncured materials from coming into contact with the skin, since people with particularly sensitive skin may be affected. The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection. The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water. The use of solvents is to be avoided. Disposable paper – not cloth towels – should be used to dry the skin. Adequate ventilation of the working area is recommended. These precautions are described in greater detail in Vantico publication No. 24264/3/e Hygienic precautions for handling plastics products of Vantico and in the Vantico Material Safety Data sheets for the individual products. These publications are available on request and should be referred to for fuller information. All recommendations for the use of our products, whether given by us in writing, verbally, or to be implied from the results of tests carried out by us, are based on the current state of our knowledge. Notwithstanding any such recommendations the Buyer shall remain responsible for satisfying himself that the products as supplied by us are suitable for his intended process or purpose. Since we cannot control the application, use or processing of the products, we cannot accept responsibility therefor. The Buyer shall ensure that the intended use of the products will not infringe any third party’s intellectual property rights. We warrant that our products are free from defects in accordance with and subject to our general conditions of supply. Vantico Adhesives and Tooling Duxford, Cambridge England CB2 4QA Tel: +44(0)1223 832121 Fax: +44(0)1223 493322 www.Vantico.com © V a n ti c o , 2 0 0 2 ® Agomet is a registered trademark of Vantico AG, Basel, Switzerland Publication Number A 486 a GB Provisional Page 2 of 2