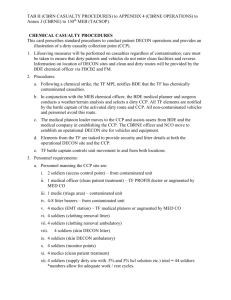

CHEMICAL, BIOLOGICAL, AND RADIOLOGICAL DECONTAMINATION

advertisement