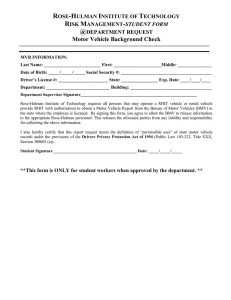

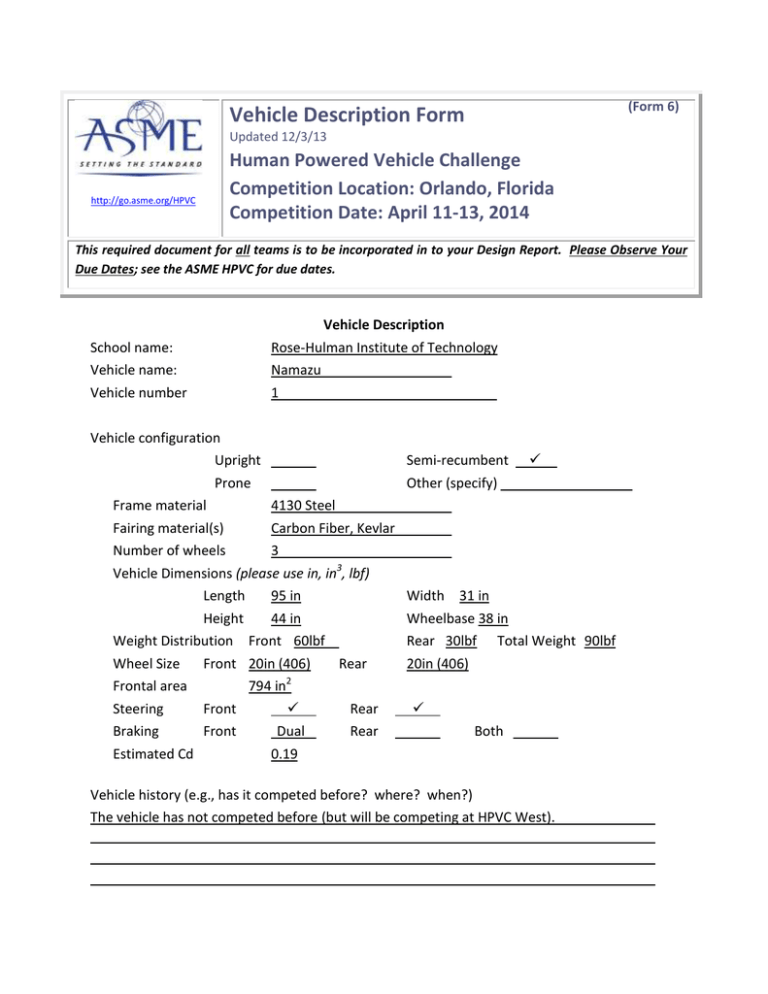

Vehicle Description Form

advertisement