ISPE Biopharmaceutical Baseline Guide Jeff Biskup, CRB Omaha, Nebraska April 14, 2005

advertisement

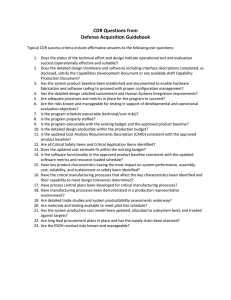

ISPE Biopharmaceutical Baseline Guide Presented by: Jeff Biskup, CRB At Omaha, Nebraska April 14, 2005 Biopharm Baseline Guide Presentation Overview Jeff Biskup, CRB – Background, Intro/Overview and Process Utilities Mark VonStwolinski, CRB – Facilities Issues Pat Hamell, Pfizer – Process Equipment & Manufacturing Issues and Real Life Applications First Some Background Biopharmaceutical Industry Evolution Biopharmaceutical Industry is Evolving – Transitioning from » R&D focus to commercial manufacturing » Small entrepreneurial companies becoming big businesses Biopharmaceutical Baseline Guide will significantly impact industry. Where has it Been? Primarily in R&D, most recently heavy in Development Mostly technology based entrepreneurial operations Mostly located in R&D centers Staffing predominantly PhD’s and highly creative developers Where is it Now? Transitioning to commercial production for blockbusters – Learning how to produce GMP products – Moving to industrial regions Building MEGA plants for large scale production Building clinical production operations Matching up business partners Recognizing the importance of being in manufacturing regions Where is it Going? There will be: – More companies manufacturing GMP biotech product & many larger companies – Multi-product producers with many small products Companies will need to learn to produce cost competitive products for smaller patient markets Some Key Challenges Resulting from the Evolution Needed Resources: – Efficient production facilities » Few licensed facilities – Experienced workers » Development » Construction » Production » Support services Some Key Challenges Resulting from the Evolution What is wrong with existing biotech staff? – Not enough of them – Few are experienced in large scale GMP production Some Key Challenges Resulting from the Evolution Challenges converting existing pharma company staff for biotech – Processes significantly different » More vulnerable to bioburden issues » Not accustomed to processing conditions conducive to developing biological contamination » New or evolving product lines and processes pose challenges And then came the Biopharmaceutical Baseline Guide How will the Biopharmaceutical Baseline Guide help to resolve these challenges? As a Training Tool The Guide provides fundamental information regarding bioprocess operations – Describes general principles of bioprocess operations – Identifies process operations where product is vulnerable – Highlights differences with conventional pharmaceutical operations Helping Harmonize Pharmaceutical Regulators Worldwide ISPE Baseline Guides focus on fundamental principles of GMP – What is critical to producing quality products consistently and reliably? Fundamentals help unify regulators and minimize focus on special/regional interests Providing Background for Evolving Manufacturing Operations Guide presents substantial information relative to: – Multi-product manufacturing » Cleaning operations » Product segregation strategies – Various production scales And Now The Guide Goals & Objectives of the Biopharmaceutical Baseline Guide Balance capital, risk, and operating cost Get CBER, CDER and field buy-in – Understand Team Biologics Consistency in best practices Clarify and document common industry issues Reduce ambiguity in requirements Address multi-product manufacture Reduce start-up and qualification efforts Baseline of critical regulatory issues, not a textbook AND to Promote the BASELINE Philosophy Focus investment on facility issues that effect our goal to produce quality pharmaceutical products and devices reliably and consistently. Avoid unnecessary spending on facility features that do not contribute to that goal. The Steering Team Co-Chairmen – Richard Priester – Mel Crichton – Jan Gustafsson - Novo FDA – Kip Priesmeyer Team – – – – – – – – – – – – – Geoff Attenborough - Amgen Gary Bird - Lilly Jeff Biskup - CRB Ken Jacobson - CRB Tom Keuer - Baxter Steve Miller – Wyeth Biopharma Noshir Mistry – BristolMyers Squibb Mark vonStwolinski – Dowler Gruman Jeff Sarvis – Fluor Patricia Turney - Amgen John Ward – Biogen Depak Agarwal – Jacobs Jeff Odum – CRB Additional Participants in the Biopharmaceutical Baseline Guide Steering Committee = Writers – Industry + Engineers + FDA contact Chapter Teams = primary review Industry review: – Focus Groups – Presentations – Industry Reviewers FDA Reviewers – Content locked in after FDA comment Industry Reviewers Over 100 people – Discussion Team – Writers – Reviewers Representation – – – – – Pharma Biotech Engineering Consultants Contract Manufacturers Equipment Manufacturers FDA Reviewers Supporting Kip Tom Arista - National Expert, Team Biologics - Dallas Janice Brown - CBER reviewer (licensing) - Rockville Mark Brunswick, PhD - CBER Reviewer (prod spec) - Bethesda Earl Dye PhD - CBER Reviewer (prod spec) - Bethesda Jay Eltermann - CBER John Finkbohner PhD - CBER reviewer (licensing) - Rockville Rick Friedman - CDER Office of Compliance - Rockville Jim Giefer - Drug Specialist - St Louis Dennis Guilfoyle, Ph.D. - regional micro lab Mariza Jafary - Team Biologics - Los Angeles Kevin Kallander - Sterility Specialist - Denver Steve Kilker - Investigator - Cincinnati Joe McGinnis, Drug Specialist, North Brunswick, NJ to the FDA Rick Thornton - Team Biologics - Buffalo Chapters of the Biopharmaceutical Guide 1: Introduction 2: Concepts & Regulatory Philosophy 3: Manufacturing Activities / Operations 4: Process & Equipment Considerations 5: Process Support 6: Facility Integration 7: Process Controls & Automation 8: Commissioning & Qualification 9: Glossary 10: (Appendix) European Aspects Chapters 1 & 2 Introduction & Regulatory Concepts Provides broad introduction to Guide and perspective on Regulatory Concepts – Principles of Product Protection – Controlled bioburden processing versus aseptic processing – Open versus closed processing – Multi-product issues Chapters 1 & 2 Introduction & Regulatory Concepts Introduce concepts like – Segregation – Biohazard containment – Cleanability – Area cleanliness classification Chapter 3 Manufacturing Operations Procedural and Operational Controls – Open vs. closed process Bioburden-controlled processing Viral clearance/inactivation Segregation methods Multiple product operations CT materials manufacture Chapter 4 Process and Equipment Organization – PFDs for Typical Biopharmaceutical Processes – Critical Process Parameters – General Considerations for Equipment Design – Specific Equipment Design Considerations Chapter 4 Process and Equipment General Considerations – Integration of equipment design with facility – Process Closure – Materials on Construction – Biohazards – Cleaning – Modular Equipment Chapter 4 Process and Equipment Specific Equipment Design Considerations – Raw Material Storage/Handling/Dispensing – Media/Buffer/Component Prep/Hold – Inoculum Prep – Fermentation/Cell Culture – Recovery/Harvest – Purification BioProcess Equipment Design Consdierations Figure 4.1 - Design Considerations Solution Preparation: Media Buffer C C Cell Culture Microbial Fermentation Recovery: Centrifugation Cell Disruption Microfiltration Depth Filtration Extraction Refold Expanded Bed Chromatography Purification: Ion Exchange Chromatography Affinity Chromatography Hydrophobic Interaction Chromatography Size Exclusion Chromatography High Pressure Liquid Chromatography Precipitation Chemical Treatment Ultrafiltration / Diafiltration Nanofiltration C C Bulk Formulation / Bulk Fill Sterilize-in-Place Clean-in-Place C C C C C C C C C C C C C C C C N N C C C C C C C C N N N N C C N C C C N N N N N C C N N C C N N C C C N N N C C C C C C N C N N N Vis co sit y Om sm o la li ty Co nd uc tivi Ste ty rilit y Bio Bu rde n Gr ow th R a te Ce ll C on ce Pro n tr du ati ct on Co Ce nc ll C en ult t ra ure tio Ot n By he rB -pr od y-p Yie u rod ct ld Pr uc ot e ts ins Sta bili ty Pro du ct Ide Pu nti ri ty ty En do tox in Vir al Cle ara Co nc mp e os iti o no fP Process Steps & Unit Operations Ho mo ge ne Sh i ty ea /U r nifo Te rm mp i ty e ra t u pH re CRITICAL PROCESS VARIABLES C C C C N N C C C N C C C C C C N N C C N N C C C C C C C C C C C C C N C C C C C C C N C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C N N C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C N C C C C C C C C C C C C C C C C C C C C C C C C N C C C C C C C C C C C C C C C C C C N N N N N N C C C C N C N N C C C C C C C C C C C C C C LEGEND: C Typically a critical variable N A design consideration, but not usually a critical variable Usually not a design consideration Rev. St. Louis - April 2003 Chapter 5 Process Support Pharmaceutical Water Systems Cleaning, Sterilization and Depyrogenation Systems Process & Utility Gases Process Temperature Control Systems Bio-waste & Process Waste Handling Seal Support Systems Plumbing & Piping Systems Emergency Power Chapter 5 Process Support Assess GMP impact of each system Methods to minimize product contamination risk – Minimize need to access the process area – System Layout and Routing Potential contamination sources and cures Key concepts for biopharmaceutical water & cleaning systems System Layout and Routing Centralized vs Decentralized Services Centralized Services – Advantages » May reduce capital cost » May improve maintainability and operability » Easier to provide redundancy – Disadvantages » May increase cross contamination risks • May increase operational complexity Decentralized Services – Advantages » Better product segregation » May simplify operations – Disadvantages » May increase cost » Duplicated systems and operations » Redundancy is expensive System Layout and Routing Use of Unclassified Manufacturing Space Minimizes need to access to classified area Reduce gowning time and costs Reduces product exposure potential Creates heightened awareness in critical areas Pharmaceutical Water Systems Reference Baseline Guide to Pharmaceutical Water & Steam Focus on issues unique to Biopharma Nutrient water feed covered as process step Pharmaceutical Water Systems Importance of delivery temperature Methods to achieve low or ambient temp at POU Impact of these issues on design Chapter 5 Process Support Includes discussion of water cooling approaches not in the ISPE Water/Steam Baseline Guide Restriction Orifice (mount in vertical) Hot Loop Hot Loop Coolant Coolant T Point Of Use Point Of Use Installed in Subloop Relative Advantages of Water Cooling Alternatives Table 5.1 . DESCRIPTION Water Guide Fig. 8-10 Single Point of Use Steamed ADVANTAGES DISADVANTAGES COMMENTS Simple connections & operations. Reliable performance once properly flushed and tested. Superior microbial control for intermittent use points. HX is continuously sanitized except when in use. Potentially many HX installations with potentially significant water consumed for flushing. Difficult to control flushing & mirror Higher pressure drop in distribution piping system. See Note A. Most advantageous when few low temperature users. Water Guide Fig. 8-12 Point of Use HX with Multiple Branched Users Water Guide Fig. 8-11 (Modified) Multiple Branched Users Cooling by Process Vessel See Note B Extensive start-up flushing required to sanitize multiple points of use. See Note B Superior microbial control for intermittent use points. HX is continuously sanitized except when in use. Utilizes heat exchanger required by process in lieu of dedicated. Pressure drop in distribution piping from HX’s in series. Most advantageous when a few units can serve most low temp users. Added time to cool down may not effectively utilize installed equipment. May require oversizing of tank cooling systems. Most advantageous when cool down time is available. May not be optimum utilization of critical and expensive process components. Ambient or Cold Distribution Generally lowest cost for operation and installation. May require relatively frequent sanitization and associated time when only high temperature water is available. May require that high temp water be occasionally available through CIP circuit. Most advantageous when 4 hr. period at high temp operation is possible. Water Guide Fig. 8-11 Single Point of Use Installed in Sub-Loop Table 5.1 Notes: A. B. Heat exchanger and associated piping and traps consume critical clean room space. Relatively fewer but larger heat exchangers. Most advantageous with few low temp users and relatively short distribution runs. Conclussion Publication of ISPE’s Baseline Pharmaceuticals Guide will be a great tool for the evolving bioprocess industry Thank You Any Questions???