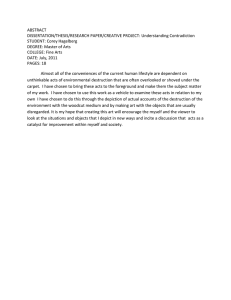

STUDY REPORT Provisional Translation MAY 1999 TECHNOLOGY STUDY GROUP

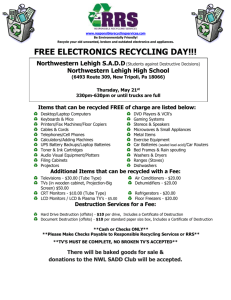

advertisement