Document 11612149

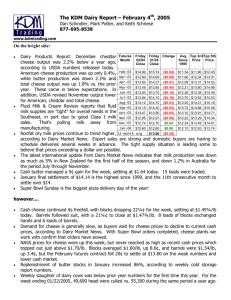

advertisement