AN ABSTRACT OF THE THESIS OF

advertisement

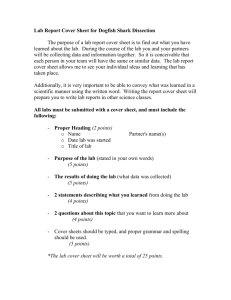

AN ABSTRACT OF THE THESIS OF Jeffry Dean Culbertson for the degree of Master of Science in Food Science and Technology presented on "TTtnnPyU ID, IQ05? Title; ACID STABILIZATION OF AUTOLYZED FISH; STORAGE AND NUTRITIONAL CHARACTERISTICS Abstract approved; rr-™-- „,,—.^^ Dr. David 1^. Crawford The effects of ambient temperature storage on the chemical and nutritional characteristics of phosphoric and sorbic acidstabilized fish autolysates were determined. Variations in sample composition due to autolysis, deboning, and acidification were also evaluated. Autolysates of English sole (Parophrys vetulus), true cod (Gadus macrocephalus), Dover sole (Microstomus pacificus), and orange rockfish (Sebastodes pinniger) carcass wastes, whole Pacific hake (Merluccius productus) and dogfish shark (Squalis acanthias), and a hake/tuna viscera (70/30 wt/wt) mixture were utilized in the investigation. Samples were acidified to ca. pH 3.25 with phosphoric acid (85% w/v) and contained potassium sorbate at the 0. 2% (wt/wt) level. Screen separation of bone reduced the ash levels of samples, with the exception of dogfish shark. Loss of bone minerals, spe- cifically calcium and phosphorus, was responsible. Phosphoric acid addition elevated ash and phosphorus contents to higher levels than for raw materials. Acid-stabilized autolysates were stable to microbial outgrowth throughout 8 months of ambient temperature storage. creases in pH levels were generally observed. Slight in- Sorbate levels de- creased at an apparently exponential rate with respect to time (r=-.9146, P > .005). Hydrolytic rancidity did not proceed during storage. Stability towards microbial outgrowth, inactivation of endogenous lipases during pasteurization, and maintenance of acidic environmental conditions enhanced fat stability. Oxidative rancidity, as measured by 2-thiobarbituric acid (TBA) numbers, progressed during storage. Carcass wastes showed higher rates and overall levels of oxidation. Initial free fatty acid levels correlated in a linear manner with 0 and 4 month TBA numbers (r=:. 9548, P > . 005; r=. 9187, P >. 005, respectively). The regression of TBA numbers at 4 months on zero time values increased in a linear manner (r=. 9346, P > . 005). Proteolysis during storage, as monitored by free amino groups, was not detected. Inactivation of native proteases during processing and the microbial stability of samples were responsible. Levels of available e-amino lysine and tryptophan were stable throughout storage. The protein quality of acidified hake, dogfish shark, orange rockfish, and English sole autolysates, stored for 0, 4, and 8 months, was evaluated using protein efficiency ratio (PER) determinations. Protein quality was not affected by storage in samples of acidified hake, English sole, and orange rockfish (P=.05). Ratios for all samples of hake and the 0 and 8 month samples of dogfish shark did not vary significantly (P=.05) from the casein control. English sole and orange rockfish samples yielded PER values that were inferior to casein and round fish samples (P=. 05). The regression of feed consumption and PER values on TBA numbers decreased in a linear manner (r=-. 7999, P > . 005; r=-.8424, P > . 005, respectively). Higher contents of nutritionally inferior visceral proteins and increased rates of oxidative rancidity in the carcass waste samples probably were responsible for their reduced protein qualities. Acid Stabilization of Autolyzed Fishs Storage and Nutritiojial Characteristics by Jeffry Dean Culbertson A THESIS submitted to Oregon State University in partial fulfillment of the requirements for the degree of Master of Science June 1978 APPROVEDs Professor of Food Science and Teoeiiology in charge of major Head of Department of Food Solence and Technology Dean of Graduate School Date thesis is presented n^c\^oV> \ O ^ lOj^lfi Typed by Opal Grossnicklaus for Jeffry Dean Culbertson ACKNOWLEDGMENT The author wishes to express sincere gratitude to Dr. David L. Crawford for his many years of guidance and support. Thanks are also given to Duncan K. Law, Dr. Dennis T. Gordon, Dr. Jerry Babbitt, and the staff of the Astoria Seafoods Laboratory for their worthy advice, cooperation, and endless patience. I am also indebted to Dr. A. F. Anglemier and Dr. W. D. Davidson for their timely contributions to a balanced education. Appreciation is extended to Bioproducts, Inc. , Warrenton, Oregon and to the National Oceanic and Atmospheric Administration (maintained by the U. S. Department of Commerce) Institutional Sea Grant 04-6-158-44094 and 04-7-158-44085 for partial support of this investigation. TABLE OF CONTENTS INTRODUCTION 1 REVIEW OF LITERATURE 4 Industrial Fish Products Meals, Oils and Solubles Direct Animal Feeds Non-edible products Fish Silage Production Storage Characteristics Fish Protein Concentrates Processes Nutritional Characteristics Autolysis of Fish Proteins MATERIALS AND METHODS Preparation of Samples Apparatus Autolysis and Stabilization of Samples Mineral Composition Storage Characteristics Stability towards Microbial Outgrowth Lipid Stability Protein Stability Protein Quality Stability RESULTS AND DISCUSSION Sample Composition Storage Characteristics Stability towards Microbial Outgrowth Lipid Stability Protein Stability Protein Quality Stability 4 4 6 7 7 8 9 10 11 12 13 16 16 17 17 18 18 19 19 21 22 23 23 28 28 37 43 49 SUMMARY 56 BIBLIOGRAPHY 59 LIST OF FIGURES Figure 1. 2. 3. Page Loss of sorbic acid during storage of acidstabilized autolysates. 32 Log of % sorbic acid retained (based on initial contents) versus storage. 34 Malonaldehyde levels (mg/kg) in stored acidstabilized autolysates. 41 LIST OF TABLES Table 1. Page Proximate composition of raw, autolyzed and deboned, and acid-stabilized fish samples. 24 Macromineral content of raw, autolyzed-deboned, and acid-stabilized samples. 26 Micromineral composition of raw, autolyzeddeboned, and acid-stabilized samples. 27 4. Effect of storage on pH. 29 5. Sorbic acid levels (% wt/wt) of stored acidstabilized autolysates. 31 Regression of the log % sorbic acid retained on storage time (mos). 35 Stability of acidified autolysates toward microbial outgrowth (organisms/gm x 10 ). 36 Free fatty acid levels (% wt/wt in total lipid expressed as oleic acid) in stored acid-stabilized autolysates. 38 Malonaldehyde levels (mg/kg) in stored acidstabilized avitoly sates. 40 Proteolysis (mg glycine equivalents/16 gm total N) in stored acid-stabilized autolysates. 44 Available e-amino lysine content (gm/16 gm total N) of stored acid-stabilized autolysates. 46 Tryptophan content (gm/16 gm total N) of stored acid-stabilized autolysates. 48 Protein efficiency ratio (PER) of stored acidstabilized autolysates. Summary of analysis of variance; factorial design. 50 2. 3. 6. 7. 8. 9. 10. 11. 12. 1 3. Table 14. Page Protein efficiency ratio (PER) of stored acidstabilized autolysates. Summary of analysis of variance. Randomized block design; ranking of individual treatment means. 52 ACID STABILIZATION OF AUTOLYZED FISHs STORAGE AND NUTRITIONAL CHARACTERISTICS INTRODUCTION The increasing population of the world has sharpened the demand for high quality protein and made it imperative that none of our potential harvest from the ocean be wasted. While there remains consider- able disagreement about the extent to which the seas can provide increasing amounts of food for man, there is general agreement that the present catch can be substantially increased. The 197 3 world landings of 145 billion pounds of seafoods represented an approximate 20 percent harvest of the estimated resource (U. S. Fish and Wildlife Ser. , 197 3). Increasing the total catch is not the only method of providing more fish protein. Solid waste from fish processing plants consti- tutes a significant portion of the highly nutritional catch from the sea. The overall loss of protein for fish processed for human consumption is estimated to be approximately 50 percent (Finch, 1970). The annual U. S. volume of solid fishery wastes thus gener- ated is about 1.2 billion pounds (Soderquist et al. , 1970) and only 50 percent of this waste is recovered for animal feeds. Based on an estimated mean protein content of 14 percent, the remaining 600 million pounds of waste would represent approximately 84 million pounds of protein. The under utilization of fishery waste not only represents a significant loss of high quality protein, but creates environmental and economic problems. Until recently, solid fishery wastes were disposed of in one of the following manners? incineration, dumping into waterways, or landfills (Kreag and Smith, 1970). In these days of increasing environmental concern, public pressure and more stringent pollution control laws have caused more emphasis to be placed upon developing methods for transferring seafoods processing waste into saleable products (Crawford, 1976). Marketable products for which fishery waste could be utilized as a raw material include meals, pelletized animal or fish foods, silage, fertilizers, fish glues, oils and protein concentrates (Brody, 1965). Upgrading or recovering the high grade proteins from seafood wastes (or more appropriately expressed "secondary raw materials") will, directly or indirectly, assist in solving the world protein shortage and reduce pollution problems. , For the past several years various research projects at the Oregon State University Seafoods Laboratory, Astoria, Oregon have been undertaken to find avenues of utilization for various fishery wastes, as well as for "trash" or undesirable species of fish. Fish with this unappropriate designation include hake, spiny dogfish, dogfish shark (mammal), and starry flounder. Although the abundance of "trash" fish, particularly the Pacific hake (Merluccius productus ), was once ignored and often irritating, it is now recognized that such fish could make a substantial contribution to the Pacific fishery, particularly as a raw material for protein concentrates (Finch, 1970). The production of fish protein concentrates (FPCs), based upon the hydrolytic or autolytic digestion of fishery wastes or "trash" fish, has been under investigation for several years. Normally, preservation of such concentrates depends upon the energy intensive removal of water to produce a dry powder. The objectives of this investigation were to (1) evaluate the stabilization of autolyzed fish and fishery wastes using phosphoric and sorbic acids for storage at ambient temperatures and (2) to determine the chemical and nutritional effects of such treatment. LITERATURE REVIEW Industrial Fish Products At the present time the bulk of industrial fish products is produced from species too small, boney, or oily for direct human consumption (Bucove and Pigott, 1976). The term "industrial fish" has been used to define fish which are processed directly into feedstuffs for the production of livestock such as chicken, beef, and pork. This classification includes species such as herring, menhaden, anchovie, and sprat (Windsor and Thomas, 1974). Slightly over 50 percent of the 4. 8 billion pounds of fish caught in the U. S. in 197 3 was converted directly into industrial products (U. S. Fish, and Wildlife Ser. , 197 3). Meals, Oils and Solubles Fish meal, which has won wide acceptance in the feed trade because of its proved nutritional value, is obtained through the "fish reduction process" which consists essentially of grinding, cooking, pressing and drying of whole fish or fishery waste (Brody, 1965). Depending on the raw material and the desired end-products, two general types of reduction, wet and dry, can be used. The wet reduction process utilizes live steam under pressure to soften the flesh and bones and to release the oil. Pressing the cooked material expels the liquid portion, known as the "press liquor," and 5 produces a "presscake" which is subsequently dried and ground. The "press liquor" is processed by continuous centrifugation to obtain fish body oils and "solubles." In the past the "solubles, " containing water soluble vitamins and a variety of proteins, were discarded (Brody, 1965). However, current technology involves either concen- tration to yield a product with approximately 50 percent solids which can be marketed separately, or complete dehydration and restoration to the presscake meal (Karrick, 196 3). As the name infers, dry reduction utilizes dry heat to cook and dehydrate raw fish material which is subsequently ground to produce a meal. The process has several advantages over the wet reduction process; namely, the water soluble materials are retained in the meal and batch processing allows for changes in operating conditions when a variety of raw materials is processed (Brody, 1965). How- ever, the high fish oil content of meals produced in this manner has limited their use in animal feeds. The protein content of fish meals varies from 55 to 70 percent by weight. Herring meals have the highest protein content, while fish scrap meals exhibit the lowest values (Nilson, 1950). Fish meal proteins contain all of the essential amino acids and are particularly nutritionally valuable because of their relatively high content of lysine (McBride et al. , I960). Supplementation of animal feeds, whose pro- tein content is based primarily on cereal sources and are deficient in this amino acid, represents the largest current use of fish meals (Finch, 1970). Direct Animal Feeds Industrial fish and fishery wastes have wide application in the broad field of animal feeding. They are utilized extensively in pet food formulations, particularly for cat food, in rations for fur bearing animals, and for the preparation of pelletized rations for various species of fish (Brody, 1965). European technology also includes the production of fish silage which is used extensively in swine production (Tatterson and Windsor, 1974). In 1973 over 116 million pounds of pet foods was produced in the U.S. (Fishery Statistics, 1973). Comparing this value with the 1958 production of 3 million pounds (Jones, I960) indicates the dynamic nature of the pet food industry. Although the lower protein content and high mineral content of most fishery wastes limits its scope of utilization in certain pet food formulations, machine separation of skin, flesh, and bone could yield highly nutritional proteinaceous raw materials for such products (Crawford jit ah (1972). Crawford ^t al. (1972) found the protein quality, as measured by protein efficiency ratio (PER) evaluations, of machine separated flesh from fillet carcass wastes to be superior or equal to casein. The use of fishery wastes in the preparation of rations for domestically reared fish for human consumption or governmental propagation efforts represents a means of recycling protein resources. Fillet carcass waste, generated in large quantities during the processing of groundfish for human consumption, was found to be a satisfactory replacement for round fish (such as turbot) in the formulation of Oregon moist pellets (Crawford, 1976). Non-edible Products A wide variety of non-edible products can be produced from industrial fish and fishery wastes. These include liquid fish glues, gelatin, leathers, and fertilizers (Brody, 1965). Numerous proces- sing techniques and patents have been developed for the manufacture of non-edible products, however, with the increased food demands of today, greater economic emphasis has been placed on the utilization of fishery wastes as protein sources for consumption by fish, livestock, and man (Tannenbaum et al. , 1974). Fish Silage Fish silage is commonly defined in the literature as a liquid product made from whole or parts of fish to which no other material has been added other than an acid. Liquification of the fish mass is carried out by enzymes already present in the fish. True ensilage differs from this in that the breakdown is accomplished by the action 8 of lactic acid bacteria (McBride et ah , I960). Liquification of fish silage usually occurs over a period of several weeks; the rate of autolysis being dependent on the ambient temperature, pH, and the relative amount of visceral organs present (Mackie, 1974). Ensilage processes have been most extensively studied in the Scandinavian countries where liquified fish products are utilized primarily as protein supplements for swine (Tatterson and Windsor, 1974). Several advantages of having animal ration supplements in liquid, rather than solid form, are apparent. transported in bulk. Liquid products can be readily Secondly, liquid protein supplements can act as binders in otherwise dry rations. A third advantage is that a liquid product could theoretically be produced at a lower cost since the energy costs of drying and grinding could be saved. The trans- portation of bulk water is one obvious disadvantage for liquid products. Production The principle involved in the manufacture of fish silages is based upon the rapid action of endogenous enzymes spread throughout the fish mass by grinding and mixing and accelerated by favorable conditions of acidity. Acid conditions also inhibit bacterial out- growth during the process. been used. Various acids or mixtures of acids have The first successful process, developed in Finland in the 1920's, utilized acidification to pH 2. 5 with a mixture of sulfuric and hydrochloric acids (Tatterson and Windsor, 1974). Work done by Hanson and Lovern (1951) indicated that acidification to pH 4 with formic acid produced an acceptable product which was superior to those produced by mineral acids because neutralization prior to feeding was not required. (1974). This was confirmed by Tatterson and Windsor McBrideetal. (I960), however, found that liquification occurred more rapidly in silages acidified to pH 3 with mineral acids and that neutralization was not necessary if the supplement did not exceed 20 percent of the diet. Storage Characteristics The effects of storage on freshly prepared silage are primarily reflected in changes in the protein and lipid fractions. Studies by various workers show an increase in soluble nitrogen levels, indicating that a rapid breakdown of proteins to low molecular weight peptides and free anaino acids occurs. Tatterson and Windsor (1974) found that the rate of change decreased greatly after approximately one month of storage when 75 to 85 percent of the total nitrogen content was soluble. McBrideetal. (I960) and Mackie (1974) indicated that the rate of protein hydrolysis was dependent upon the pH, ambient temperature and relative amounts of visceral organs present. The level of free fatty acids, as dictated primarily by the action of endogenous Upases, rises rapidly during the first month of storage, reaching 10 levels as high as 20 percent of the total lipid present (Tatterson and Windsor, 1974). Fish Protein Concentrates Fish protein concentrates (FPCs), often containing over 90 percent protein, have been proposed for use in various parts of the world as an important source of inexpensive complete protein for both man and animals (Finch, 1970). There is no singular FPC, rather a family of products each with its own characteristic balance of physical, nutritive, and sensory properties and cost which makes it applicable to one particular area of usage. Processes for the pro- duction of FPCs consist primarily of stages of separation and concentration. They have in common the concentration of protein; the stabilization of the product against the growth of microorganisms, mostly by reduction of the water level; and its stabilization against chemical change, especially lipid oxidation, by removal of the lipid fraction (Tannenbaum et al. , 1974). In the United States, the produc- tion of FPC for human consumption is limited by the Food and Drug Administration to the species of fish (hake and hake-like fish, menhaden, and herring of the genus Clupea) and the solvent extraction process (extraction with isopropyl alcohol or with ethylene dichloride followed by isopropyl alcohol) used and requires the product to meet certain chemical and nutritional specifications (Kreag and Smith, 1973), 11 FPC Processes The processes involved in the production of FPC can be categorized into the following general classifications; 1) solvent extraction, 2) non-solvent extraction, and 3) biological (Finch, 1970). The solvent extraction processes utilize lipid solvents to extract nonpolar compounds, such as oils, and may or may not remove water from the ground, deboned raw material. Various solvents, including isopropyl alcohol, ethylene dichloride, acetone, and hexane, have been utilized (Tannenbaum et al« , 1974). The extracted material is then dehydrated yielding a product with 80 to 95 percent protein (Yanezetal. , 1967). Problems stemming from the use of solvents in FPC production, namely residual solvent toxicity and loss of protein functionality due to denaturation, have precipitated research into FPC production using non-solvent techniques. Various patents have been developed which rely on the use of alkali to dissolve the protein in the raw material. Freed oil is separated by centrifugation and protein is recovered by subsequent acid precipitation (Tannenbaum, 1970). Surface active agents have also been proposed as alternatives to the use of solvents, but the procedures currently suffer from technological problems (Connell, 1969). Three biological approaches have been studied in the manufacture 12 of FPC. These include the use of microorganisms and the use of endogenous or exogenous enzymes (Finch, 1970). Regardless of the approach, the main objective is to hydrolyze or solubilize the proteins present in the raw material so that oil separation is facilitated and a maximum of protein functionality is retained. Burkholder jst al. (1965) reported the discovery of two microorganisms which were able to hydrolyze fishery wastes and produce acceptable products. The use of Aspergillus species followed by yeast to ferment fish has been investigated by Jeffreys and Krill (1965). Nutritional Characteristics Numerous references to studies on the nutritional quality of FPCs prepared from different species and various processes have been reported. With few exceptions, FPCs have been shown to be high in protein with a quality at least equivalent to casein when evaluated by laboratory animals (Finch, 1970). The amino acid pattern of an "average" FPC compares favorably with those of egg and milk; methionine, isoleucine and total aromatic amino acids levels are somewhat lower and lysine levels higher (FAO, 1965). Methionine has been shown to be the first limiting amino acid in FPC (Miller, 1956, Yanez^tal. , 1967, and Stillings et al. , 1969). A variety of studies have amply demonstrated that FPC supplementation at levels from 3 to 8 percent can effectively enhance the 13 quality and quantity of protein in foods that contain proteins of vegetable origin (Finch, 1970). The addition of 3. 5 percent FPC to either rice, wheat, or corn increased protein efficiency ratio by 35, 100, and 300 percent, respectively (Sidwell _et al. , 1970). Power (1964) compared the nutritive value of FPC prepared from whole fish, fillets, headed and eviscerated fish, and processing scrap. The use of either headed and eviscerated fish or fish scrap had little effect on the protein quality of FPC as compared to that made from whole fish. Tarkey jst al. (197 3) and Pigott and Chu (1969) have produced FPC from fishery wastes that are nutritionally equivalent to casein. Autolysis of Fish Proteins The preparation of liquified fish products based on autolytic activity has been extensively studied in Japan, where a variety of products for human consumption are produced, and in various Scandinavian countries which utilize fish silages as animal feeds. Ensilage processes depend primarily upon the addition of acids to modify the environmental pH to enhance the activity of various endogenous proteolytic enzymes and to prevent microbial growth. Wide variations in the time required for autolysis or liquification have been reported (Tatterson and McBride, 1974). Autolytic activity of various species of fish has been found to be affected by several parameters 14 including season of the year and dietary intake (Kaiwai and Ikeda, 1973). Freeman and Hoogland (1956) found that the quantities of digestive enzymes present in cod and haddock viscera were sufficient for autolysis at native pH in a 48 hour period. McBride jet al. (1961) reported the complete autolytic digestion of whole Pacific herring in 72 hours. The entire mixture was acidified to pH 2 with hydrochloric acid and maintained at 37 C. Liquification of ground whole herring, acidified to pH 4. 0 with formic acid, was accomplished in 48 hours by Tatterson and McBride (1974). Sullivan (1975) reported that extracts of whole tuna viscera yielded protease activity optimums at pH 1.5, 3. 1-3. 5, and 9-5, with an approximate 30 fold increase in activity from pH 6. 0 to 3. 5. Work by Timmerman (1977) indicated that the optimum pH for hydrolysis of whole hake was approximately pH 3. 5-3. 6 at 55 C. A pH 3. 0 optimum at 30 C was obtained in similar work by Koury (1971). The optimum pH for the liquification of whole hake based upon viscometric properties was found to be between 4. 3 and 5. 1 which varied considerably from that for overall proteolytic activity (pH 3. 6-3. 7) (Timmerman, 1977). It was theorized that since the connective tissue of the fish was degraded releasing bone, protease systems specific for connective tissues with higher pH optimums may have been responsible for the enhanced liquification. 15 The optimum temperature for the broad mix of proteases contained in whole hake has been shown to be near 60 C (Timnnerman, 1977 and Koury, 1971). Proteases contained in the pyloric caeca of albacore tuna showed activity near 60 C, but were rapidly inactivated at higher temperatures (Sullivan, 1976). 16 MATERIALS AND METHODS Preparation of Samples Samples of Dover sole (Microstomus pacificus), true cod (Gadus macrocephalus), English sole (Parophrys vetulus), and orange rockfish (Sebastodes pinniger) carcass wastes were obtained through Astoria Seafoods, Inc. , Astoria, Oregon. Round Pacific hake (Merluccius productus) and dogfish shark (Squalis acanthias) samples were obtained from Pacific Shrimp, Inc. , Warrenton, Oregon. Twenty-four hours prior to digestion, samples were passed through a dual-cut meat chopper equipped with a 1/2" plate, packed into 1" x 4" x 24" stainless steel trays, and frozen at -34.4 C (-30 F). Immediately prior to processing, the frozen blocks were removed from the trays and passed twice through a 1/4" plate of the chopper. The resulting minced material was then held at 2 C until digestion. A sample of albacore tuna (Thunnus alalunga) viscera was obtained soon after evisceration of thawed frozen fish from Bumble Bee Seafoods, Inc. , Astoria, Oregon. The viscera sample was immediately frozen (-34.4 C), cut into slabs, vacuum sealed in moisture-vapor proof film, and held at -17.7 C (0 F). The frozen viscera was passed twice through the chopper equipped with a 1/4" plate prior to its use. 17 Apparatus Samples were digested using a reaction unit developed by Duncan K. Law of the Oregon State University Seafoods Laboratory, Astoria, Oregon. The digestion unit consists primarily of an open sample vessel, equipped with a stirring device, a pump, and a simple shell-in-tube heat exchanger. Hot water served as the exchange medium during digestion, while live steam was introduced into the heat exchange system to achieve pasteurization temperatures. Reac- tion mixture temperatures were controlled by thermostatically activating the water flow through the heat exchange system. Autolysis and Stabilization of Samples Processing waste from Dover and English sole, orange rockfish and true cod and round dogfish shark and hake and a hake/tuna viscera (70/30 wt/wt) mixture were included in the investigation. Approxi- mately 125 kg of minced sample was utilized in each digestion run. Samples were heated to 55 C in the digestion unit and held at this temperature for a period of 1 hr. to effect liquification. Bone par- ticles were subsequently removed by passing the liquified material through a 30 mesh screen. The sample was then heated to 83. 7 C o (180 F) for five min to inactivate native enzyme systems and effect pasteurization. Using cold water as the exchange medium, the 18 sample was cooled to ca. 25 C, pumped into 50 gal plastic drums, and held at 2 C overnight. quantities of H PO The cooled material was stabilized with (85% wt/wt) required to achieve a pH of ca. 3. 25 and 0.2% potassium sorbate (wt/wt). The samples were then stored at ambient non-heated room temperature. Mineral Composition The mineral composition of the initial raw material and their resulting deboned and acid stabilized autolysates was determined. Approximately 500 gm of each sample was dried in vacuo at 65 C and passed through a 1 mm sieve of a high speed mill (with dry ice when necessary). Mineral composition was determined by emission spec- troscopy (WARF Institute, Madison, Wisconsin). The moisture con- tent of raw and autolyzed samples was determined by AOAC (1970) procedures so that mineral composition could be expressed on a wet weight basis. Storage Characteristics Various chemical and biological assays were performed at 0, 2, 4, 6, and 8 months of storage to determine the stability of the acidified autolysates towards microbial outgrowth and to assess deteriorative changes in their protein and lipid fractions. At appropriate times samples were placed in styrofoam containers, frozen at -34. 4 C 19 (-30 F), vacuum sealed in moisture-vapor proof film and stored at -17.70C (0OF) for later analysis. Stability toward Microbial Out-growth Changes in acidic conditions and microbial numbers were determined during storage to evaluate the degree of autolysate stability. The pH of each sample was determined at 0, 1, 2, 3, and 4 days and at 2, 4, 6, and 8 months of storage. Sorbic acid levels were moni- tored using a spectrophotometric method developed by Wilamowski (1974). The method relied on the ether extraction of the protonated form of the acid, followed by a quantification based on absorption at 250 nm. A sample of the potassium sorbate used to stabilize the autolysates, dried under vacuum at 65 C for 4 hr, was used in the preparation of a standard curve. Total aerobic plate counts were determined according to AOAC (1970) procedures. Serial dilutions 2 3 4 5 6 9 of IslO , IslO , IslO , IslO , 1;10 and 1; 10 were used and plates exhibiting between 30 and 300 colonies after 2 days of incubation at o 37 C were counted. Lipid Stability The level of hydrolytic and oxidative rancidity that developed during storage was estimated by the determination of free fatty acid and malonaldehyde (2-thiobarbituric acid numbers) contents, 20 respectively. A modified Folch (1957) procedure was used to extract lipid from which sample free fatty acid levels were determined. A 5-10 gm sample was. homogenized for 2 min in a Virtis blender with 20 volumes of CHCl ;CH OH (2/1 v/v). Solids were separated by vacuum filtration through a Buchner funnel fitted with Whatman No. 1 filter paper. The filtrate was quantitatively transferred to a 500 ml glass stoppered graduated mixing cylinder. (w/v) CaCl A volume of 0. 05% solution equivalent to 20%-of the filtrate volume was added and mixed by gentle inversion. The phases were allowed to separate overnight at 0 C and the interfacial volume of the CHCl layer was recorded. The aqueous phase was removed and a 100 ml aliquot of the CHCl phase was placed in a pre-weighed 250 ml rour^d bottomed flask. The sample was dried under nitrogen on a rotary evaporator and the flask weighed to determine the total lipid weight. Free fatty acids were determined by direct titration according to procedures outlined by Smith et al. (1957) and expressed as % free oleic acid based on total lipid weight. A procedure described by Sinnhuber and Yu' (1977) was used for the determination of 2-thiobarbituric acid (TBA) numbers. The procedure is based upon the reaction of malonaldehyde (released during the oxidative deterioration of polyenoic fatty acids) in the intact sample lipid fraction with 2-thiobarbiturate yielding a pigment 21 which is spectrophotometrically quantified at 5 35 nm. TBA numbers represent the milligrams of malonaldehyde present per kilogram of sample. Protein Stability The degree of protein hydrolysis occurring during storage was evaluated by determining the formation of free amino nitrogen. Free amino nitrogen was determined using the ninhydrin analysis carried out according to Moore and Stein (1954) and reported as mg glycine/16 gm total sample nitrogen. Total nitrogen content was determined using the semi-micro Kjeldahl procedure (AOAC, 1970). The levels of available lysine were estimated using the spectrophotometric method developed by Carpenter (I960). The analysis is based upon the formation of dinitrobenzene derivatives of the constituent amino acids. Lysine derivatives were separated on the basis of their water solubility and quantified by their absorbtion at 435 nm. Values were expressed as gm lysine/16 gm total sample nitrogen. A standard curve was prepared using free e-amino lysine hydrochloride, obtained from Nutritional Biochemicals Corp. , Cleveland, Ohio. The tryptophan content of samples was estimated using a method outlined by Spies (1950). The procedure involved the reaction of p-dimethylaminobenzaldehyde with tryptophan residues, under 22 strongly acidic conditions, to produce a chromophore which absorbs at 590 nm after exposure to light. Tryptophan hydrochloride obtained from Nutritional Biochemicals Corp. , Cleveland, Ohio was used to prepare a standard curve. Results were expressed as gm tryptophan/ 16 gm total sample nitrogen. Protein Quality Stability Acid stabilized autolysates of English sole, dogfish shark, hake, and orange rockfish, stored for 0, 4, and 8 months at ambient temperatures were selected for nutritional evaluation. At appropriate storage times, approximately 7 kg samples were frozen into blocks at -34.4 C (-30 F), placed in large plastic lined storage bags, and o o held at -17. 7 C (0 F) prior to analysis. Autolysates were mixed approximately 2s 1 (wt/wt) with corn starch, drum dried, and passed through a 0. 02 in. sieve of a high speed hammermill for incorporation into rations. The addition of corn starch facilitated drum drying and assured thorough milling. The protein efficiency ratio (PER) of samples was determined by AOAC procedures using a ANRC reference casein (Humko Sheffield Chemicals, Lyndhurst, N. J.) control and ten male rats per assay group. Data were analyzed by analysis of variance and the differ- ences in means determined by Duncan's multiple range test. 23 RESULTS AND DISCUSSION The utilization of fishery wastes and "trash" fish as sources of high quality protein represents a significant means by which rising world food demands may be satisfied. This investigation was designed to assess the effects of phosphoric and sorbic acid stabilization on autolyzed fish materiaL Stabilization by this method would allow preservation without costly refrigeration or dehydration. Parame- ters evaluated included the effect of processing and acidification on sample mineral and proximate composition, and the effects of ambient temperature storage of acid-stabilized autolysates with regards to microbial outgrowth, lipid and protein stability, and nutritional characteristics. Sample Composition The proximate compositions of raw, autolyzed and deboned, and acid-stabilized fish samples are shown in Table 1. The removal of bone fragments following autolysis resulted in decreased ash levels for all samples except dogfish shark. This observation would be ex- pected since members of the shark family rely on collagen, rather than bone, for supportive structures. Acidification of samples with phosphoric acid (85% w/v) to pH 3. 25 resulted in the elevation of ash levels to values higher than for the raw materials. Although moisture (0 en J3 I T) ■H O <i a o XI <u a •v 0 u o to o 6 o u o u ft (ti XI (U u ft a •H (U 4-> O u ft (ti 03 XJ < 3 (U O U NO ON oo m rj m o on so "^ en en in Tt1 ON oo m ■^ [^- oo NO vD in oo »-( o ^f c^C^ oo ■—i en oo c") NO (\j —< ON roo o r- M m in in in Tj( m in ON NO ON ON NO ON ^ <M NO en (M CM oo ON o oo c^ O M N£> r^ ■^ m eo -^ (\j TJI rj* ^H [NON NO (\J t-H oo en en o en oo ^ en 00 in (M M O ON nH oo r~ oo '^ oo ^H en .-H Tjt vO (M NO rt< T}< O •st* en so oo •* oo -^ O in r(M Tf r^ ^ (M in r^ oo <\j ON ON^Hvoeor-enm I-H ND ON oNenf-eoooenm oo o oo ■<* m t- ON r~<N^-(MNO(\jin p-H O •—< ^ ^H fNJ ^H eo o NO oo r~- ON ON (\J ^H (\J r- m ^ oo oo (\j -^ o rj en t— oo -H oo oo en (\j Tf en r-H -X) t- en in ON NO eO r- ON m ON oo <\j ■-< NO ^H ON 00 O 00 (M NO O ^H ON O C^ <M O ri p p a w H a NO NO 00 NO ON ON en so NO vo r^ NO NO r^ o > r-n ON m oo m oo rr- ND r^ r^ r^ r^ 1^- Ui in rt Q Q Sg w H x 2 a a aG ffi tr! ffi o en o •<# oo r~ r- r- oo r^ r^ r^ ON NO h w U > (2j Q Q K W H ffi pci pd pi tf pci crj a5 M 24 (U a (ti XI (ti to XI xj to •H >+H CuO O o m P u « p •^ p o .. ^1 TJ <u o M ti 0) (ti 3 M u 0 +> II II ft U rt H •«» •• <u -H o m T3 (1) • r-l 4-1 Tt XI W u CO (ti on II ti < W n »o. G O ^^^ X3 +> -(-> <u * Tt >N OJ (ti u T) & 0> N o >, en XT ■--. o o r)-l XI X) II (0 a • ow • •. > £ (ti (ti (ti J* jj II -u |H cd a ii <D XI ^H a 6 (ti w 25 and protein levels decreased upon acidification of autolyzed samples, close inspection reveals that this observation is probably due to a replacement or dilution effect caused by the addition of phosphoric acid. The levels of macrominerals (P, K, Ca, Mg, and Na) for samples of raw, hydrolyzed-deboned, and acidified fish materials are listed in Table 2. Autolysis and deboning resulted in decreased levels of phosphorus and calcium as cpmpared to starting raw materials for all samples except dogfish shark. Magnesium levels also decreased slightly for all samples at this stage of processing. Acidification of autolysates with phosphoric acid resulted in increased levels of phosphorus; all samples except orange rockfish exhibited levels decidedly higher than those for raw fish materials. Acid stabilization decreased levels of calcium, magnesium, and sodium in relation to those for autolyzed-deboned samples reflecting the dilution of the ash contents by added phosphoric acid. The precipi- tation of insoluble calcium and magnesium phosphate complexes may have complicated sampling techniques and might have been a factor in this observation. Potassium levels, overall, did not substantially decrease after acidification. The addition of 0.2% (wt/wt) potassium sorbate at the time of acidification probably contributed to the finding. Table 3 lists the micromineral (Al, Fe, Sr, B, Cu, Zn, Mn, and Cr) composition of the raw fish materials, autolyzed-deboned, (0 —I m ID n) J3 I O a) T3 C <4 a o A (U T) I T» <U N n5 -p o o —I a! u <D O u o (VJ (U H •4-) M u a a •H o u o z so flj U W ^ T3 O u o o f—i sD in i—i o r—( (M p—H • i—1 r-H vO i-H ■* i-H CM oo r~ 1—1 i-H CO sO o CM i—i o o ^ in d d d d d co m ^ r- ■* oo oo o CM i—i d o d odd cr- m i—i o in ro CM (M o o 00 ^H sO sO m ^H <\J 00 o vO r-H r-H O CVJ r—t f! O NO o oo o CM i—i i—i (M o -x> • 00 oo 00 OO •<*< o (M ■* i-H vO CM I—H d d in r- o rO 00 o 00 (M —i o oo m r- CM ■* o in CM i-H OO r-H ■* oo rt< o CM ■—i i-H i-H CM CM CO CM o CM a^ in « d o m oo o ■* •* -* (M 00 CO o i-H i-H d d CM r-H o m in m r~ 00 i-H r-H vO d odd d d d d d d odd d d d d d ,-H CM o r- r- CM i—t d d o d d MOO sD in CO T^ r—( o o 00 oo CO (N] tCM o in o co r- ■—i in o CO r^- a- rg t- -o o m CM <M •* oo o co og o oo i—< o OO CM o "tf -i o (M CM o o o o o o o o o o o o o o o O O o o o o d d d odd d <M O oo o o o ■* a O •* O r-H oo oo sO o M m o o m C\] cr> f\] oo CM i—i sO <\j vO CM ro t- in CM o o in T—1 00 oo r—t OO CM CM O o d i-H CM i-H i-H a* vO oo d d d ^ oo cr- -t ^X) en m ■—i vO oo m oo CO in oo oo co oo CM o d d d odd h h h U U u > > > X X X Q Q Q 0 Q P ffi pci PJ H H H W H W oi X < Pi X < oi X < rt x <; PS X < Pi X < d d d d d *! d d odd d d d d d d odd d d d d d d CO oo m 00 o (M M 00 (M CO oo d odd 00 o m oo rr~ (M o d ^h oo ro o O vD .—( Tf O ffi ffi ffi rt ffi < o OO o c^ «J M D U M 'si a 0) n 26 CO xl (U <-> bo o lH O 0 -a •rH ^! VI U co w 0 n n CO o CO X! ao •rH —H n Q n g a W n X! T) M UJ ^H m o > w fc u W ffi Q BS H T) D a O XI <u tJ T) <V N T) >s (U o ^ fll n > u Q U Xj >s (t) II CCi M XI II P II II Pi X < ffi 6 27Table 3. Micromineral composition of raw, autolyzed-deboned, and acid-stabilized samples. Micromineral (ppm wet weight) Al Fe Sr B Cu Zn Mn Cr RH 22.2 23.4 34.2 1.4 1. 3 11.6 2.4 1. 3 HH 13.6 26.9 12.9 1.0 4.8 19-9 1. 3 0.9 AH 77.4 11. 5 7. 1 1.8 2.9 8. 1 0. 3 1.0 RHV 11.8 38.9 16. 1 1.0 2.5 19.1 1.4 0.9 HHV 10.4 39.2 4.6 0.7 4.0 18.6 0.8 0.6 AHV 64.6 27.8 2.5 2.0 1.2 14.4 0. 3 0.9 RD 26.0 39.9 37.2 1.6 1. 3 18.8 2.6 1.6 HD 15.4 55. 3 10.1 1. 1 3. 1 14.2 1.0 0.6 AD 154.2 19.5 3. 3 3. 1 2.4 12. 3 1.0 1.6 RDS 19- 6 21.0 21.0 1.4 1.5 8.6 1.0 1.5 HDS 28,9 81.7 10. 1 1. 1 1.8 8.7 1.2 0.9 ADS 142.8 5.7 5.7 2.5 1.0 6.6 0.2 1.6 RRF 27. 6 18.6 55.6 2. 1 1.5 9-6 0.6 2.7 HRF 12.8 36.7 28.0 1.0 2.5 4.9 0.2 1. 1 ARF 70.2 5.9 2. 5 1.6 1.6 4.8 0.3 1.5 RTC 24.6 29.0 61.8 1.7 1. 5 ■ 12. 1 1.7 1.8 HTC 13.4 36.7 20.9 0.8 2.7 10.9 0.8 0.6 ATC 58.4 16.6 12.8 5.2 3.8 15. 3 1.4 3.4 RE 107.0 193. 1 87.6 3.6 2. 1 18. 3. 5.9 3.9 HE 85.6 163.0 24.8 1.9 2.7 14. 6 3.6 1.9 AE 104.6 30.7 7.4 2.4 1.0 8.5 2.0 1.9 Code 1 ■ Samples R = rav/, H = hydrolyzed/deboned; A = acidified; H = hake; D = Dover sole; HV = hake/tuna viscera (70/30 wt/wt); DS = dogfish shark; RF = orange rockfish; TC = true cod; E = English sole. 28 and acidified (zero time) autolysate samples. Manganese levels decreased due to deboning processes for all samples except dogfish shark. The removal of bone minerals resulted in increased levels of iron and copper in all samples. Acidification subsequently lowered levels of these minerals by either dilution with phosphorus or through the formation of insoluble complexes which may have adversely affected sampling procedures. Storage Characteristics Microbial Outgrowth The influence of ambient temperature storage on the maintenance of acidic environmental conditions was investigated. The influence of storage time on the pH of acid-stabilized fish autolysates is shown by values listed in Table 4. Carcass waste (English and Dover sole, orange rockfish and true cod) and round dogfish shark required the addition of ca. twice the amount of phsophoric acid (85% w/v) to achieve a pH of ca. 3. 25 compared to round hake samples. The in- creased acid requirement of carcass waste was probably related to neutralization by a higher bone-fragment and shell content of the carcass waste over round hake. The higher bone content of carcass waste would increase the amount of small bone fragments that would not be removed by screening. Carcass wastes also possessed a higher amount of digestive tract contents per unit weight than round hake Table 4. Code Effect of storage on pH. % H3P04 (85% w/v) Storage time (days) 0 1 2 Storage time (mos 3 2 4 6 AH 4.5 3.22 3. 33 3.44 3.36 3. 38 3. 37 3.41 3. 31 3.44 AHV 4.5 3.24 3. 36 3. 38 3. 37 3.40 3.47 3.41 3.53 3.49 AD 8.5 3. 19 3.28 3. 30 3. 30 3. 34 3. 52 3.47 3.41 3.50 ATC 8.5 3.21 3.20 3.21 3.21 3.21 3.19 3.20 3.24 3.19 AE 8.7 3. 17 3.25 3.28 3.25 3.26 3. 34 3.21 3. 31 3.29 ARE 9.0 3. 18 3.20 3.24 3.23 3.24 3. 33 3. 37 3.40 3. 38 ADS 7.8 3.21 3. 10 3.09 3. 10 3. 11 3.07 3.09 3. 13 3.16 1 Samples A H D TC = = = = acidified hake Dover sole true cod HV E RF DS = = = = hake/tuna viscera (70/30 wt/wt) English sole orange rockfish dogfish shark 30 adding proportionately more bone and shell derived from partially digested food. The urea content of the dogfish shark sample probably increased its requirement for acid over round hake. The pH of all samples, with the exception of true cod and dogfish shark, rose slightly (5-10% of initial values amounting to 0. 120. 31 pH units) over the 8 months storage period. Increases in pH were most marked during the initial 4 days of storage, with only slight fluctuations evident during the remainder of the storage period (Table 4). No increase in the pH of true cod or dogfish shark samples was observed. Tatterson and Windsor (1974), McBride et al. (I960), and Hanson and Lovern (1951), found that pH levels for fish silages prepared with a variety of mineral acids remained constant during storage at ambient temperature for periods up to one year. Changes in pH during the initial 4 days of storage reflected the neutralization of acid by dissolution of bone salts or the delayed establishment of a pH equilibration due to the large sample size (ca. 50 gal). The sorbate content of all samples decreased during ambient temperature storage; the majority of change was apparent during the initial 2 months of storage (Table 5; Figure 1). The largest decrease (77%) was observed for the Dover sole sample, while the smallest loss (39%) was shown by the hake sample. Pooled retention values (based on % initial sorbate retained) for samples prepared from carcass Table 5. Sorbic acid levels (% wt/wt) of stored acid-stabilized autolysates. Storage time (mos) Code 0 2 4 6 8 AH 0.211(100)2 0. 128(61) 0.072(34) 0.023(11) 0.014(7) AHV 0.230(100) 0.076(33) 0.028(12) 0.023(10) 0.007(3) AD 0. 197(100) 0.045(23) 0.037(19) 0.026(13) 0.009(5) ATC 0.201(100) 0.068(34) 0.028(14) 0.017(8) 0.012(6) AE 0.211(100) 0.086(41) 0.072(34) 0.059(28) 0.030(14) ARF 0.207(100) 0.056(27) 0.033(16) 0.017(8) 0.017(8) ADS 0.214(100) 0.066(31) 0.056(26) 0.043(20) 0.019(9) 0.210(100) 0.075(36) 0.046(22) 0.029(14) 0.015(7) Group Average Sample: A = H = D = TC: = acidified hake Dover sole true cod '( ) = % of zero time level HV E RF DS = = = = hake/tuna viscera (70/30 wt/wt) English sole orange rockfish dogfish shark 100 .a 2 50- storage (mos) 0=hake |_J = Dover sole } = hake/tuna viscera B = true cod ( 70/30 wt/wt) Figure 1. /\ = English sole \/ = dogfish shark ^^ = orange rockfish Loss of sorbic acid during storage of acid-stabilized autolysates 33 waste (English and Dover sole, orange rockfish and true cod) and round fish (hake, hake/tuna viscera (70/30 wt/wt), and dogfish shark) were 28% and 45%, respectively, for the first 2 months of storage. The log of pooled sorbic acid retention values for all samples decreased in a linear manner with respect to time (r:=-. 9146, P> . 005) strongly supporting an exponential decay in stored acidstabilized autolysates (Figure 2). Statistical inspection of data for individual samples revealed the rate of decay (as indicated by the slope) was highest for the hake/tuna viscera (70/30 wt/wt) sample followed by true cod, hake, Dover sole, orange rockfish, dogfish shark, and English sole (Table 6). The correlation of the regression of the log of retention values with respect to time were all significant at at least the P> .025 level. The rate of sorbate decay in acid- stabilized autolysates did not correlate with the microbiological load (Table 7) of the samples. Heat treatments provided during the autolysis and pasteurization stages of sample preparation greatly reduced the microbial load of the raw materials. Although sorbic acid levels decreased greatly, acid-stabilized autolysates were stable toward microbial outgrowth during the storage period (Table 7). This indicates that either preser- vation was effected solely by the addition of phosphoric acid or mold inhibition was possibly due to a sorbic acid metabolite. Marth et al. (1966) studied the metabolism of sorbic acid by Penecillium species 2.0« i.sc O 6^ CO 3 0.5Equation: y = -0. 1379) x + 1. 90 Correlation • oefficient = -. 9155 -1 4 " "" Storage time (mos) Figure 2. Log of % sorbic acid retained (based on initial content) versus storage. 35 Table 6. Regression of the log % sorbic acid retained on storage time (mos). Code AH 98872 -.1527 AHV 98202 -.1782 AD 94633 -.1425 ATC 97482 -.15 36 AE 95063 -.09 37 ARF 93003 -.1310 ADS 95423 -.1141 pooled; 91562 -. 1379 Sample: A H D TC 2 P > .005 3 P > .025 m r = = = = acidified hake Dover sole true cod HV E RF DS = = = = hake/tuna viscera (70/30 wt/wt) English sole orange rockfish dogfish shark Table 7. Stability of acidified autolysates towards microbial outgrowth (organisms/gm x 10 ), Storage time (mos) 2 0 4 6 8 45 5.0 6.5 4.8 5. 1 4.6 126 TFC2 3.2 4.6 3.8 3.6 60 3.0 7.8 5.4 12. 1 15.2 35,000 30.0 26.0 34.0 17.2 21.4 AE 560 52.0 12.6 17.0 34.0 18.8 ARF 250 46.0 54.0 36.0 31.0 21. 3 ADS 81 5.5 8.8 6.7 10.6 7. 3 Raw Code AH AHV AD ATC 1 Samples A H D TC = = = = acidified hake Dover sole true cod HV E RF DS = = = = hake/tuna viscera (70/30 wt/wt) English sole orange rockfish dogfish shark 'Too few to count a- 37 of molds and proposed the theory that sorbic acid metabolites may interfere with dehydrogenases associated with (3-oxidation. The metabolism of sorbic acid by molds to an inhibitory compound which was not detectable may explain both the exponential decay rate previously noted and the stability towards mold outgrowth of the samples. It should be noted that although the acid-stabilized autolysates were stable to microbial outgrowth in the 8 month study, several samples exhibited rapid spoilage shortly after termination of the experiment. Although the exact cause of this occurrence was not determined, it presumably was due to sorbate depletion. Long term storage of acid-stabilized autolysates, therefore, would require the periodic addition of potassium sorbate to maintain microbial stability. Lipid Stability The levels of free fatty acids, as an indication of hydrolytic rancidity, remained relatively constant throughout storage (Table 8). Since the autolysates were found to be stable toward microbial growth, this tends to indicate that endogenous lipases were inactivated by processing and non-enzymatic base-catalyzed hydrolysis was inhibited by maintenance of acidic environmental conditions. A wide range of zero time individual sample levels from 3. 4% for dogfish shark to 22. 30% for hake/tuna viscera (70/30 wt/wt), was observed. Initial free fatty acid levels may have been influenced by Table 8. Free fatty acid levels (% wt/wt in total lipid expressed as oleic acid) in stored acid-stabilized autolysates. Storage time (mos) 1 0 2 4 7. 65 ± 0. 34 5. 85 ±. 0.71 6.28 ± 0. 53 7.91 ± 1.01 6.41 ± 0.42 AHV 22. 30 ± 1.46 19-82 ± 0.90 24. 91 ± 0. 73 23. 36 ± 1. 86 21.47 ± 1. 24 AD 11. 80 ± 0.83 11.93 ± 0.77 11.23 ± 0.66 8.48 ± 0.45 10.47 ± 0.67 ATC 19. 37 ± 1.27 23. 66 ± 1. 31 23.53 ± 0.74 20. 14 ± 0.96 22.76 ± 0.88 AE 7. 10 ± 0. 18 8.90 ± 0. 31 6.86 ± 0. 87 9. 34 ± 0.24 7.44 ± 0. 33 ARF 6.23 ± 1. 17 8.47 ± 0. 69 7.73 ± 1. 11 8. 31 ± 0. 73 8. 08 ± 0. 64 ADS 3. 14 ± 0. 62 2.09 ± 0. 56 6. 19 ± 0.69 4.42 ± 0.84 6. 11 ± 0.93 Code AH 1 Samples A H D TC = = = = acidified hake Dover sole true cod HV E RF DS = = = = 8 hake/tuna viscera (70/30 wt/wt) English sole orange rockfish dogfish shark 'n = 2 u> oo 39 several factors including the handling of samples prior to acquisition, the composition of samples with regards to endogenous lipase content, and non-enzymatic base-catalyzed hydrolysis prior to and during processing. Carcass and visceral wastes from the fish processing industry are frequently allowed to remain at ambient temperatures prior to disposal. During this time the action of endogenous lipases and microorganisms may proceed unchecked. hydrolysis may occur. In addition, simple non-enzymatic The high microbial load of the true cod sample (Table 7) indicates the existence of such a situation and may explain the high initial free fatty acid level of this sample. The lipases of fish are largely confined to organ tissue (Brody, 1965). Carcass waste samples and hake with added tuna viscera, therefore, possessed higher levels of endogenous lipases than round fish samples. This would presumably result in the production of higher initial levels of free fatty acids during processing. A compari- son of the zero time free fatty acid levels for the hake and hake/tuna viscera (70/30 wt/wt) samples, 7. 65 and 22. 30% respectively, illustrates this point. Oxidative rancidity, as measured by 2-thiobarbituric acid numbers, developed in all samples during storage (Table 9). Values for all samples except hake and dogfish shark rose rather rapidly during the. first 2 months of storage (Figure 3). The largest increase Table 9- Malonaldehyde levels (mg/kg) in stored acid-stabilized autoly sates. 1 1 Storage time ( mos) 4 Code 0 2 AH 2. 31 ± 0. 342 2.96 ± 0.41 AHV 6.96 ± 0.51 AD 6 8 4.81 ± 0. 36 3.86 ± 0.27 5.46 ± 0.73 10.41 ± 1. 11 16.72 ± 1.03 12.42 ± 0.84 11.87 ± 1.99 4.92 ± 0. 67 12. 13 ± 1.46 11.73 ± 0. 38 14.89 ± 1.48 16. 16 ± 1.57 ATC 5.54 ± 0.81 9.43 ± 0.78 12.46 ± 1. 16 8. 19 ± 0.84 6.42 ± 1.89 AE 5.21 ± 0. 36 8.97 ± 0.63 14. 69 ± 1.42 13. 32 ± 1.19 13.92 ± 1.86 ARF 6.85 ± 0.99 20.77 ± 1.61 16.40 ± 1.93 17. 16 ± 1.84 15.98 ± 1.27 ADS 3.54 ± 0.23 3.48 ± 0.40 8.29 ± 1. 10 7. 64 ± 0.66 10.43 ± 0.73 Sample; A H D TC = = = = acidified hake Dover sole true cod HV E RF DS = = = = hake/tuna viscera (70/30 wt/wt) English sole orange rockfish dogfish shark 'n = 3 o 41 storage time (mos) O = hake /\ = English sole ^ J^ = orange rockfish = hake/tuna viscera/ 70/'30 wt/wt) ll = Dover sole ^f = dogfish shark H = true cod Figure 3. Malonaldehyde levels (mg/kg) in stored acid-stabilized autolysates. 42 was shown for the orange rockfish sample; its 2-thiobarbituric acid (TBA) number tripled in 2 months. Tatterson and Windsor (1974) reported that although the acid-stabilized silage they prepared was stable to hydrolytic rancidity, oxidative rancidity, as measured by iodine value, proceeded unchecked throughout ambient temperature storage. Statistical evaluation of data for hydrolytic and oxidative rancidity revealed that free fatty acid levels at zero time correlated in a linear manner with 0 and 4 month TBA values (r = . 9548, P > . 005; r=.9187, P>.005, respectively). Conditions which lead to the ap- pearance of free fatty acids in the zero time samples may have been conducive to the oxidation of lipids, e. g. , the poor handling of raw materials with regards to conditions of time and temperature prior to sample procurement. A second possible explanation may be that the free fatty acids present at zero time may have been more susceptible to oxidation than intact triglycerides. Zero time TBA values correlated (r=. 9346, P > . 005) in a linear manner with 4 month values. Since lipid oxidation proceeds through hydroperoxide formation and free radical propagation, the presence of oxidized lipid at zero time would explain the continued increase to 4 month values. The TBA numbers for samples of orange rockfish, hake/tuna viscera (70/30 wt/wt), and true cod rose and subsequently decreased 43 during storage (Figure 3). Variations may have been due to sampling techniques or a portion of the malonaldehyde originally released through oxidation may have reacted with protein present in the sample to form a linkage which inhibited detection. Protein stability The protein fraction of the acid-stabilized autolyzed fish samples was stable toward acid catalyzed proteolysis during storage. The levels of free amino groups (as measured by ninhydrin) did not appreciably vary with time (Table 10). The stability of the samples towards mierobial outgrowth and the inactivation of endogenous proteases during pasteurization (180 F/83. 7 C for 5 min) are most likely responsible for this observation. Sullivan (1976) reported the complete inactivation of proteases isolated from the pyloric cacea of albacore tuna fish (Thunnus alalunga) by heating to 70 C for 10 min. Work by Katsuma et al. (1974) supported these findings. The levels of free amino groups indicate that the degree of proteolysis that occurred during processing was the greatest for the hake/tuna viscera (70/30 wt/wt) sample, followed by hake, the carcass wastes (English and Dover sole, orange rockfish and true cod), and dogfish shark. The apparently higher degree of proteolysis for whole hake, as compared to the carcass wastes whose content of viscera was higher, is interesting. The feeding rate of fish greatly Table 10. Proteolysis (mg glycine equivalents/16 gm total N) in stored acid-stabilized autolysates. Storage time (mos) Code 2 4 6 8 8.94 ± 1.04 9. 36 ± 1. 36 9.69 ± 0.89 9.42 ± 1. 11 11. 67 ± 1.46 12.21 ± 1.06 11.99 ± 1.40 11.44 ± 0.78 11.81 ± 1. 17 AD 6.45 ± 0.89 6.74 ± 0.96 6. 32 ± 0.74 7. 01 ± 1.03 6.49 ± 0.94 ATC 7.02 ± 0.70 8. 13 ± 1.24 7.97 ± 1. 13 7.46 ± 1.45 7.55 ± 1.20 AE 6. 31 ± 0.86 6. 30 ± 0.97 6.02 ± 0.73 6.41 ± 1. 14 6.68 ± 1.23 ARF 7.26 ± 0.71 6.59 ± 0.90 7.03 ± 1. 33 6.78 ± 1.26 6.92 ± 1. 34 ADS 3.69 ± 0.81 3.41 ± 0.96 3.05 ± 1. 18 3. 17 ± 0.64 3. 36 ± 0.59 AH AHV 1 Sample; 0 9.51 ± 1.212 A H D TC = = = = acidified hake Dover sole true cod HV E RF DS = = = = hake/tuna viscera (70/30 wt/wt) English sole orange rockfish dogfish shark n = 2 4^ 45 affects the proteolytic activity of the gastrointestinal tract (Kaiwai and Ikeda, 197 3). Although the carcass wastes from groundfish con- tained a higher proportion of viscera, it cannot be directly assumed that the total proteolytic activity per unit weight of material was greater than for round fish due to possible differences in feeding states prior to harvest. McBride ^t al. (I960) showed that liquifica- tion rates for silages prepared from whole versus gutted herring were essentially equal. Members of the elasmobranchii, namely sharks, rays, and skates, are known to contain rather high levels of urea in their tissues. Between 42 and 55% of the osmotically active blood solutes, amounting to approximately 2-2. 5% (wet weight) of total tissues, are in the form of urea (Smith, 19 36). The nitrogen content of urea would be determined in the Kjeldahl protein determination, but the ninhydrin assay would fail to detect its presence. Since the value for free amino groups was based on total Kjeldahl nitrogen, the presence of urea would theoretically result in low values for dogfish shark. The levels of available e-amino lysine in acid-stabilized hydrolysates were not affected by storage (Table 11). The available lysine content of carcass waste samples was lower than that of whole hake. The addition of 30% tuna viscera to the sample of whole hake reduced its lysine content. The absolute levels of available e-amino lysine in the acid-stabilized autolysates of carcass waste samples are Table I]. Available e-amino lysine content (gm/16 gm total N) of stored acid-stabilized autolysates. 1 Code 6 8 AH 6.42 ± 0.312 6.89 ± 0.46 6.91 ± 0. 15 6. 64 ± 0.61 6. 51 ± 0. 34 AHV 5.89 ± 0. 35 6.02 ± 0. 58 6. 36 ± 0.23 5.74 ± 0. 13 6. 17 ± 0.40 AD 5. 31 ± 0-61 5. 12 ± 0.22 5.69 ± 0. 37 5. 34 ± 0.46 5. 41 ± 0.71 ATC 5.56 ± 0. 14 5. 36 ± 0.66 5.89 ± 0.43 5.26 ± 0.77 5. 40 ± 0.58 AE 6.08 ± 0. 34 5.74 ± 0.49 6.70 ± 0.21 5.93 ± 0. 39 5. 59 ± 0.61 ARE 5.77 ± 0. 54 5.46 ± 0. 39 5.62 ± 0.46 5.99 ± 0.20 5. 36 ± 0.58 ADS 4.63 ± 0.28 4.81 ± 0.83 4.47 ± 0. 35 4. 55 ± 0.40 4. 42 ± 0.81 Sample: n 0 Storage time (mos;! 4 2 A H D TC = = = = acidified hake Dover sole true cod HV E RF DS = = = = hake/tuna viscera (70/30 wt/wt) English sole orange rockfish dogfish shark 47 somewhat lower than those reported by Crawford (1976) for pooled raw samples of carcass wastes of the same species. Autolysis may have converted some free e-amino lysine to lysine with both a and e groups free reducing the amount of monoderivative available for determination by the procedure used. It is also possible that some lysine destruction or interaction with oxidized lipid breakdown products occurred during processing. The values for dogfish shark are lower because of the nitrogen contribution of urea to total sample nitrogen. Tryptophan is an acid labile, essential amino acid. Possible destruction during prolonged storage in an acid environment would decrease protein quality. Tryptophan levels were stable in acid- stabilized autolysates stored up to 8 months at ambient temperature (Table 12). Carcass waste samples (English and Dover sole, orange rockfish and true cod) had higher overall levels of tryptophan than hake, hake/tuna viscera (70/30 wt/wt) and dogfish shark. The tryptophan levels for acid-stabilized carcass waste samples were approximately 30% higher than those for raw carcass wastes of the same species as reported by Crawford (1976). The method of analysis used in this investigation (Spies, 1950) has been criticized previously for yielding high values (Spies, 1967). However, for this investiga- tion the detection of overall changes in levels, rather than absolute content, was the objective. Table 12. Code Tryptophan content (gm/16 gm total N) of stored acid-stabilized autolysates. 1 2 Storage time (mos) 4 AH 1.78 ± 0.212 2.04 ± 0. 37 1.69 ± 0.09 1.90 ± 0.46 2. 17 ± 0. 18 AHV 2.21 ± 0. 36 2.46 ± 0.42 2. 05 ± 0. 17 2. 19 ± 0.20 2. 31 ± 0. 36 AD 2.89 ± 0. 11 3.07 ± 0.23 2.64 ± 0.47 3. 11 ± 0. 38 2. 69 ± 0.21 ATC 2. 63 ± 0.09 3. 18 ± 0.22 3.02 ± 0. 31 2.70 ± 0. 17 3. 37 ± 0.44 AE 3. 14 ± 0. 33 3.46 ± 0.26 2.99 ± 0. 16 3.27 ± 0.25 3. 35 ± 0. 32 ARF 3.06 ± 0. 13 2.88 ± 0.41 2.96 ± 0. 37 3.41 ± 0.40 3. 29 ± 0. 19 ADS 0.94 ± 0. 16 1.22 ± 0. 34 0.76 ± 0. 16 0.85 ± 0. 11 1. 04 ± 0.24 Sample: A H D TC = = = = acidified hak e Dover sole true cod HV E RF DS = = = = hake/tuna viscera (70/30 wt/wt) English sole or■ange rockfiLSh dogfish shark 'n = 2 oo 49 Protein Quality Stability The protein efficiency ratio of samples of acidified hake, English sole, orange rockfish, and dogfish shark autolysates stored for 0, 4, and 8 months at ambient temperatures was determined. Isonitrogenous diets, including a ANRC casein control, were utilized. Factorial analysis of data, excluding that for casein, showed that sample source and length of storage both significantly affected protein efficiency ratios (PERs) (Table 13). Weight gain was simi- larly affected, while feed consumption was affected significantly only by sample source. The interaction of sample source and storage time was significant for PER values, feed consumption, and weight gains (P > . 01; P > . 05; P > . 005, respectively). Acidified autolysates of hake and dogfish shark yielded feed consumptions and weight gains superior to orange rockfish and English sole. fish shark. The PER value for hake was superior to that for dog- Acidified orange rockfish and English sole autolysates yielded PER values which were inferior to dogfish shark and hake. Storage of samples resulted in significantly (P > .05) inferior weight gains and PER values. Protein quality reduction occurred during the first 4 months of storage. equal at 4 and 8 months of storage. affected by storage time. PER and weight gain were Feed consumptibn was not Table 13. Protein efficiency ratio (PER) of stored acid-stabilized autolysates. of variance; factorial design. Summary of analysis F-- value Sample Storage 3 12.472 38. 933 Feed (gm) 9.221 6. 691 4 4.09 Gain (gm) 72. 373 10. 582 PER 36. 13 Sample x Storage 6.71 Factor Mean Ranking' Sample Storage PER AH > ADS > ARF > AE 0 > 8 > _4 Feed (gm) ADS > AH > ARF > AE 0 > 4 > 8 Gain (gm) AH > ADS > ARF > AE 0 > 4 > 8 Significant at P > .05 2 Significant at P > .01 3 Significant at P > . 005 4 NS at P > .05 Mean values with same underline did not vary significantly (P=. 05) from each other Sample: A = acidified H = hake E = English sole DS = dogfish shark RF = orange rockfish o 51 Analysis of variance including data for the casein control showed that feed consumption, weight gain, and PER values varied significantly at levels of P > . 05, P > . 025, and P > . 005, respectively (Table 14). Although factorial analysis showed PER values affected by storage time, inspection of individual sample means (Table 14) indicated that ratios for 0, 4, and 8 month samples of acidified hake, English sole, and orange rockfish did not vary significantly ( P = . 05). The dogfish shark sample showed a significant PER decrease during the first 4 months of storage, but yielded a value at 8 months equal to the zero time sample. Weight gains for samples of hake and English sole autolysates did not vary significantly with respect to storage time. Storage of orange rockfish and dogfish shark autolysates yielded significant decreases in weight gains at 4 months. A further reduction (though not significant with the number of replicates involved) in weight gain was observed at 8 months for orange rockfish, but the weight gain for dogfish shark was equal to that for the zero time sample. Though not revealed by factorial analysis, consumption of acidified orange rockfish was significantly (P = . 05) reduced by storage. Feed consumption for other samples did not vary with storage time. The relatively high degree of oxidative rancidity that developed in the orange rockfish sample during storage, which was Table 14. Protein efficiency ratio (PER) of stored acid-stabilized autoly sates. Summary of analysis of variance. Randomized block design; ranking of individual treatment means. Code Storage time (mos) Feed consumption AH 0 363. 0 AH 4 363. 1 AH 8 349. 6 AE 0 317.4 AE AE ARF 0 4 ARF 8 ADS 0 ADS 4 Casein Sample; 8 ARF ADS 2 4 8 _ ab ab abc cd 298. 8C 284.7C 385. i' bed 325. 1 cd 310.7 369.2C ab 364.4 ab 358. 2 372. 62 Weight gain3 PER % of ANRC casein 100. 9 .ab 95. 8' abc 93. 2 ef 67.4 3.05 103.7 f 60. 6 60. 3f de 77. 6 ef 71.5 63. 5i ab 99. 1 cd 83. 6 be 88. 8 103. 8' ab 2. 91" 2.93 ab def 2. 39* 2.23 2. 34 2. 54 2.41 f def cde def .ab 2.97' 2. 72 2.94 99.8 81. 3 75. 9 79- 6 86.4 81.9 77.6 2.28 2. 56 98.9 cde be ab 101.0 87. 1 92.4 100.0 A = acidified; H = hake; E = English sole; RF = orange rockfish; DS = dogfish shark; 3 4 P > . 05; P > . 025; P > . 005; Mean values with same exponent letter did not vary significantly (P= . 05) from each other. 53 reflected by a three-fold increase in the 2-thiobarbituric acid number after 2 months of storage (Figure 3), appeared to have played a role in mediating feed consumption. The regression of feed consumption for all samples on TBA values decreased in a linear manner (r=-.7999; P > .005). Feed consumption for samples of acidified hake and dogfish shark autolysates and the zero time sample of orange rockfish was not significantly (P=. 05) different than that for casein. The lower feed consumption of acidified English sole and the 4 and 8 month samples of orange rockfish may have been responsible for their decidedly lower weight gains. Protein efficiency ratios for all samples of acidified hake and the 0 and 8 month samples of stabilized dogfish shark did not vary significantly (P=.05) from the ANRC casein control (Table 14). PER determinations for round dogfish shark were complicated by the presence of urea, resulting in lower PER values than what would be obtained if based solely upon protein nitrogen. The protein quality of acid stabilized English sole and orange rockfish was inferior to casein and round fish samples. Crawford (1976) evaluated the protein quality of several carcass wastes as compared to round turbot. Carcass wastes yielded PER values that were 80.9 to 95.7% of round turbot ratios. Olley et al. (1968) found the quality of visceral proteins of herring and whitefish, as 54 determined by net protein utilization studies, to be 72. 5 and 76. 9%, respectively, of whole herring. Low levels of histidine and possibly lysine and production of toxic factors, including histamine, prior to processing were theorized to be responsible. The higher content of nutritionally inferior visceral protein in the carcass waste samples was most probably involved in their reduced PER values. The more rapid rate and overall higher levels of oxidative rancidity in the carcass wastes (Table 9) may also have played a role in reducing their protein quality. The regression of PER values on TBA numbers decreased in a linear manner (r=-.8424; P >.005). Autooxidation of lipids yields a variety of products, including free radicals, hydroperoxides, and carbonyls, which may react with proteins to form indigestible crosslinks or block essential amino acids, resulting in a decrease in protein quality (Fennema, 1976). Roubal (1970), working with solid state model systems utilizing isolated rockfish myofibrillar protein, showed that the amino acids most sensitive to free radical attack were* in decreasing order, cystine, tyrosine, methionine, alanine, and lysine. Shin et al. (1971) found the pH optimum for crosslinking of ribonuclease with malonaldehyde to be between pH 4 and 5. Although the lysine levels of acid-stabilized carcass waste samples appeared to remain constant, it may have been possible that lipid oxidation products reacted with 55 proteins, reducing their nutritional quality, in a manner that was not detected. 56 SUMMARY The effects of ambient temperature storage on the chemical and nutritional characteristics of phosphoric and sorbic acid stabilized autolysates, prepared from fishery processing wastes and undesirable species, were investigated. The study yielded the following resultsi (1) The deboning stage of processing reduced sample ash contents, with the exception of dogfish shark; this was reflected by decreased levels of bone minerals, particularly calcium and phosphorus. Acidification with phosphoric acid increased sample ash and phosphorus contents to levels decidedly higher than for starting raw materials. (2) Acidified autolysates were stable to microbial outgrowth during 8 months of ambient temperature storage despite slight increases in pH levels and an apparently logarithmic loss of sorbic acid with respect to time (r=. 91458, P >. 005). (3) Hydrolytic rancidity, as monitored by free fatty acid levels, did not progress during storage. Inactjvation of endogenous lipases during pasteurization, maintenance of acidic environmental conditions inhibiting base catalyzed hydrolysis, and stability toward microbial outgrowth contributed to fat stability. (4) Oxidative rancidity proceeded in all samples during storage. 57 Initial free fatty acid contents correlated with 0 and 4 month levels of malonaldehyde, as determined by 2-thiobarbituric acid (TBA) numbers (r=:. 9548, P >. 005; r= . 9187, P> .005, respectively). The regression of 4 month TBA values on zero time values increased in a positive manner (r^. 9346, P > . 005). (5) Proteolysis, as monitored by the appearance of free amino groups, did not occur during storage of acid-stabilized autolysates; inactivation of endogenous proteases during pasteurization and the stability of samples toward microbial outgrowth were responsible. Levels of available e-amino lysine and tryptophan remained constant in stored acid-stabilized autolysates. (6) Protein quality, as measured by protein efficiency ratios (PER), was not affected by storage in samples of acidified hake, English sole, and orange rockfish. Ratios for all samples of hake and the 0 and 8 month samples of dogfish shark did not vary significantly (P=. 05) from the casein control. English sole and orange rockfish samples yielded PER values which were inferior to casein and roundfish samples (P=. 05). The regression of feed consumption and PER values on TBA numbers decreased in a linear manner (r=-. 7999, P >• 005; r=-.8424, P >. 005, respectively). Higher contents of nutritionally inferior visceral pro- tein and increased levels of oxidative rancidity in the carcass 58 waste samples were probably responsible for their reduced protein qualities. 59 BIBLIOGRAPHY AOAC. 1970. "Official Methods of Analysis, " 11th ed. Association of Official Agricultural Chemists, Washington, D. C. Brody, J. 1965. In "Fishery By Products Technology, " p. 100-156. AVI Publishing Company, Inc. , Westport, Connecticut. Bucove, G. O. and Pigott, G. M. 1976. Pilot plant production of a functional protein from fish waste by enzymatic digestion. Proceedings 7th National Symposium on Food Processing Wastes. U.S. Environmental Protection Agency, Cincinnati, Ohio. Burkholder, L. , Burkholder, P. R. , Chu, A. , Kostyk, N. and Roels, O. A. 1968. Fish fermentation. Food Technology 22; 1278-1284. Carpenter, K. J. i960. The estimation of the available lysine in animal-protein foods. Biochemical Journal 77;604-6l0. Connel, J. J. 1969. The fish protein concentrate story. 8. On the use of detergents in FPC production. Food Technology 2 3; 206. Crawford, D. L. , Law, D. K. , and Babbitt, J. K. 1972. Nutritional characteristics of marine food fish carcass waste and machineseparated flesh. Agricultural and Food Chemistry 20; 10481051. Crawford, D. L. 1976. Utilization of seafoods wastes. July 197 3June 1976, Astoria, 1976. 108 p. Oregon State University Seafoods Laboratory, Department of Food Science and Technology, Completion Report. Fennema, O. P. 1976. In "Principles of Food Science, " Part 1 "Food Chemistry," p. 383. Marcell Dekker, Inc. New York. Finch, R. 1970. Fish protein for human food. views in Food Technology Is519-580. CRC Critical Re- Folch, J. , Lees, M. , and Stanley, G. H. 1957. A simple method for the isolation and purification of total lipides from animal tissues. Journal of Biological Chemistry 226;497-509. 60 FAO, 1965. Protein requirements. FAO Nutrition Meetings Report Series No. 37. Food and Agriculture Organization of the United Nations, Rome, Italy. Freeman, H. C. and Hoogland, P..L. 1956. Processing of cod and haddock viscera. 1. Laboratory experiments. Journal of the Fisheries Research Board of Canada 13;869-877. Hanson, S. W. and Lovern, J. A. 1951. The use of formic acid in fish silage preparation. Fishery News 11; 1988. Jeffreys, G. A. and Krill, A. J. 1965. U.S. Patent 3, 170, 794. Jones, W. G. I960. Fishery resources as animal foods. Leaflet 501. U.S. Fish and Wildlife Service. Fishery Kaiwai, S. and Ikeda, S. 1973. Studies of the digestive enzymes of fishes. II. Effect of dietary change on the activities of digestive enzymes in carp intestine. Bulletin of the Japanese Society of Scientific Fisheries 38s265. 0 Karrick, N. L. 1963. Fish meal quality. In "Industrial Fishery Technology," p. 116. Reinhold Publishing Corp., New York. Katsuma, T. , Kuniyagawa, M. , and Togaswa, Y. ; 1974. Proteinases of the pyloric caeca. VI. Several properties of the crystalline proteinases of the pyloric caeca of tunny and bonito. Iwate Daigaku Nogakubu Hokoku (Faculty of Agriculture, Iwate University, Morioko, Japan) 12(1); 13-19. Koury, B. , Spinelli, J. and Weig, D. 1971. Protein autolysis rates at various pH1 s and temperatures in hake, Merluccius productus, and Pacific herring, Clupea barengus pallaai, and their effect on yield in the preparation of fish protein concentrate. Fishery Bulletin 69s241-246. Kreag, R. and Smith, F. J. 1973. Seafood solid waste in Oregon; Disposal or recovery? Sept. 1973. Corvallis. 21 p. (Oregon State University Extension Marine Advisory Program. Special Report 395 Department of Commerce, National Oceanic and Atmospheric Administration Sea Grant Program. ) Mackie, I. M. 1974. Proteolytic enzymes in recovery of proteins from fish waste. Process Biochemistry 9s22-25. 61 Marth, E. H. , Capp, M. , and Jackson, H. W. 1966. Degradation of potassium sorbate by Penicillium species. Journal of DairyScience 49:1197. McBride, J. R. , Idler, D. R. , and Macleod, R. A. I960. The liquefaction of British Columbia herring by ensilage, proteolytic enzymes, and acid hydrolysis. Journal of the Fisheries Research Board of Canada 18:93-112. Miller, D. S. 1956. The nutritive value of fish proteins. of the Science of Food and Agriculture 7:337. Journal Moore, S. and Stein, W. H. 1954. A modified ninhydrin reagent for the photometric determination of amino acids and related compounds. Journal of Biological Chemistry 211:907-917. Nilson, H. W. 1950. Feeding value of fish meals. Wildlife Service. Sep. No. 269- U.S. Fish and Olley, J., Ford, J. E. , and Williams, A. P. 1968. Nutritional value of fish visceral meals. Journal of the Science of Food and Agriculture 19:282-285. Pigott, G. M. and Chu, C. 1969- A new method of processing fish waste. I. The evolution of a new process. Proceedings of the 36th Annual Meeting of Pacific Northwest Pollution Control Association, Seattle, Washington. Power, H. E. 1964. Characteristics and nutritional value of various fish protein concentrates. Journal of the Fisheries Research Board of Canada 21:1489. Roubal, W. T. 1970. Free radicals, malonaldehyde, and protein damage in lipid-protein systems. Lipids 6:62-64. Shin, B. C. , Huggins, J. W. and Carraway, K. L. 1971. Effects of pH, concentration and aging on the malonaldehyde reaction with proteins. Lipids 7:229-233. Sidwell, V. C, Stillings, B. P. and Knobl, G. M. 1970. The fish protein concentrate story. 10. U.S. Bureau of Commercial Fisheries FPC's: Nutritional quality and use in foods. Food Technology 24:40. 62 Sinnhuber, R. O. and Yu, T. C. 1977. The 2-thiobarbituric acid reaction, an objective measure of the oxidative deterioration occurring in fats and oils. Journal of the Japanese Society of Oil Chemists 26(5):259-267. Smith, H. W. 1936. The retension and physiological role of urea in the elasmobranchii. Biological Reviews 11:49-82. Smith, P., Ambrose, M. E. and Knobl, G. N. 1957. An improved method for determining total lipids in fish meal. Commercial Fisheries Review 26(7): 1-5. Soderquist, M. Law, D. seafoods ence and R. , Williamson, K. J. , Blanton, G. , Phillips, D. C. , K. , and Crawford, D. L. 1970. Current practices in processing waste treatment. Department of Food SciTechnology, Oregon State University, Corvallis, Oregon. Spies, J. R. 1950. Determination of tryptophan with p-dimethylaminobenzaldehyde. Analytical Chemistry 22:1447. Spies, J. R. 1967. Determination of tryptophan in proteins. lytical Chemistry 39:1412-1416. Ana- Stillings, B. R. , Hammerle, O. A., and Snyder, D. G. 1969. Sequence of limiting amino acids in fish protein concentrate produced by isopropyl alcohol extraction of red hake (Urophycis chuss). Journal of Nutrition 97:70. Sullivan, D. P. 1975. Some visceral proteases of albacore tuna fish (Thunnus alalunga). Master's thesis, Oregon State University. Tannenbaum, S. R. , Ahern, M. , and Bates, R. P. 1970. Solubilization of fish protein concentrate. I. An alkaline process. Food Technology 24:96. Tannenbaum, S. R. 1974. In "The Economics, Marketing, and Technology of Fish Protein Concentrates. " p. 283. The Massachusetts Institute of Technology Press, Cambridge, Massachusetts and London, England. Tarkey, W. , Agarwala, O. P., and Pigott, G. A. 1973. Protein hydrolysate from fish waste. Journal of Food Science 38:917-918. Tatterson, I. N. and Windsor, M. L. 1974. Fish silage. of the Science of Food and Agriculture 25:369-379. Journal 63 Timmerman, C. D. 1977. Heat and acid induced autolytic digestion of Pacific hake (Merluccius productus). Master's thesis, Oregon State University. U.S. Fish and Wildlife Service. 197 3. Fishery Statistics of the U.S. 197 3 Final Report. Statistical Digest No. 67. U.S. Department of the Interior, Washington, D. C. Wilamowski, G. 1974. Collaborative study of a spectroscopic method for the determination of sorbic acid in fresh dairy products. Journal of the Association of Official Agricultural Chemists 57s 675-677. Windsor, M. L. and Thoma, T. 1974. Chemical preservation of industrial fish; New preservative mixtures. Journal of the Science of Food and Agriculture 25s993-1005. Yanez, E. , Ballester, D. , and Monckeberg, F. 1967. Enzymatic fish protein 'hydrolysate: Chemical composition, nutritive value and use as a supplement to cereal protein. Journal of Food Science 41s 1289-1292.