STAT 495, Fall 2003 Homework Assignment #4

advertisement

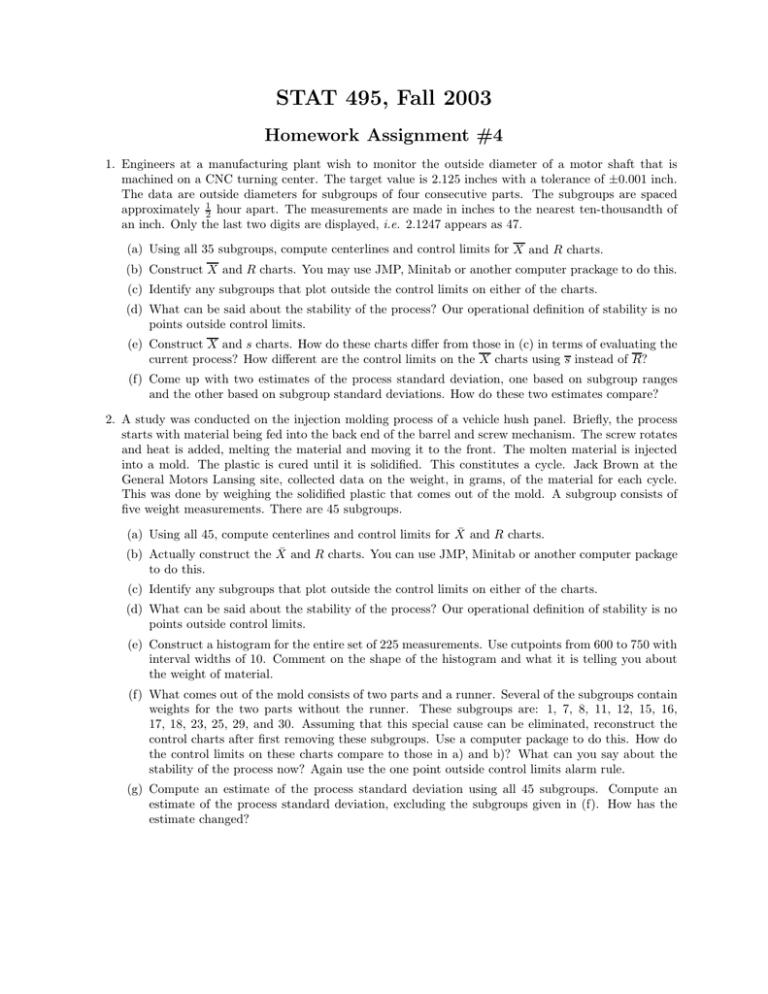

STAT 495, Fall 2003 Homework Assignment #4 1. Engineers at a manufacturing plant wish to monitor the outside diameter of a motor shaft that is machined on a CNC turning center. The target value is 2.125 inches with a tolerance of ±0.001 inch. The data are outside diameters for subgroups of four consecutive parts. The subgroups are spaced approximately 12 hour apart. The measurements are made in inches to the nearest ten-thousandth of an inch. Only the last two digits are displayed, i.e. 2.1247 appears as 47. (a) Using all 35 subgroups, compute centerlines and control limits for X and R charts. (b) Construct X and R charts. You may use JMP, Minitab or another computer prackage to do this. (c) Identify any subgroups that plot outside the control limits on either of the charts. (d) What can be said about the stability of the process? Our operational definition of stability is no points outside control limits. (e) Construct X and s charts. How do these charts differ from those in (c) in terms of evaluating the current process? How different are the control limits on the X charts using s instead of R? (f) Come up with two estimates of the process standard deviation, one based on subgroup ranges and the other based on subgroup standard deviations. How do these two estimates compare? 2. A study was conducted on the injection molding process of a vehicle hush panel. Briefly, the process starts with material being fed into the back end of the barrel and screw mechanism. The screw rotates and heat is added, melting the material and moving it to the front. The molten material is injected into a mold. The plastic is cured until it is solidified. This constitutes a cycle. Jack Brown at the General Motors Lansing site, collected data on the weight, in grams, of the material for each cycle. This was done by weighing the solidified plastic that comes out of the mold. A subgroup consists of five weight measurements. There are 45 subgroups. (a) Using all 45, compute centerlines and control limits for X̄ and R charts. (b) Actually construct the X̄ and R charts. You can use JMP, Minitab or another computer package to do this. (c) Identify any subgroups that plot outside the control limits on either of the charts. (d) What can be said about the stability of the process? Our operational definition of stability is no points outside control limits. (e) Construct a histogram for the entire set of 225 measurements. Use cutpoints from 600 to 750 with interval widths of 10. Comment on the shape of the histogram and what it is telling you about the weight of material. (f) What comes out of the mold consists of two parts and a runner. Several of the subgroups contain weights for the two parts without the runner. These subgroups are: 1, 7, 8, 11, 12, 15, 16, 17, 18, 23, 25, 29, and 30. Assuming that this special cause can be eliminated, reconstruct the control charts after first removing these subgroups. Use a computer package to do this. How do the control limits on these charts compare to those in a) and b)? What can you say about the stability of the process now? Again use the one point outside control limits alarm rule. (g) Compute an estimate of the process standard deviation using all 45 subgroups. Compute an estimate of the process standard deviation, excluding the subgroups given in (f). How has the estimate changed? Outside Diameter Motor Shafts Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 X1 48 48 50 50 51 44 51 46 54 54 57 51 42 43 41 60 48 46 52 62 58 50 47 56 39 40 48 36 51 43 43 29 36 48 45 X2 59 52 49 41 49 47 57 63 53 46 56 49 47 50 54 45 50 39 32 50 52 56 53 55 54 43 48 45 48 50 43 42 43 42 51 X3 42 51 60 48 60 54 53 63 53 55 53 67 48 44 59 52 45 43 54 47 57 44 42 44 54 59 34 43 24 40 49 43 43 43 43 X4 40 50 44 43 60 45 48 41 46 58 37 50 39 38 53 46 40 61 45 57 54 44 40 58 44 36 43 32 55 53 31 42 49 39 39 X̄ R 47.25 19 50.25 4 50.75 16 45.50 9 55.00 11 47.50 10 52.25 9 53.25 22 51.50 8 53.25 12 50.75 20 54.25 18 44.00 9 43.75 12 51.75 18 50.75 15 45.75 10 47.25 22 45.75 22 54.00 15 55.25 6 48.50 12 45.50 13 53.25 14 47.75 15 44.50 23 43.25 14 39.00 13 44.50 31 46.50 13 41.50 18 39.00 14 42.75 13 43.00 9 44.50 12 47.807 14.314 s 8.54 1.71 6.70 4.20 5.83 4.51 3.77 11.44 3.70 5.12 9.32 8.54 4.24 4.92 7.63 6.90 4.35 9.60 9.95 6.78 2.75 5.74 5.80 6.29 7.50 10.08 6.60 6.06 13.96 6.03 7.55 6.68 5.32 3.74 5.00 6.482 Injection Mold Weights Subgroup 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 X1 690 695 690 690 718 715 713 717 713 705 650 708 712 713 704 707 718 709 709 710 714 714 700 705 641 706 707 707 703 703 705 707 701 700 694 694 700 699 701 689 700 702 703 694 704 X2 690 696 690 690 719 716 712 717 714 704 711 707 710 713 645 710 719 650 708 714 713 713 699 706 701 706 705 707 702 693 703 706 700 700 695 694 699 699 698 690 699 702 703 696 703 X3 690 696 690 690 719 716 713 718 715 703 650 646 712 712 703 648 655 710 708 712 714 714 700 704 701 706 706 706 705 626 705 706 699 700 696 695 698 699 698 691 700 703 702 694 700 X4 690 694 692 689 722 717 654 658 715 704 709 704 710 712 703 709 719 647 709 708 714 712 700 703 703 706 704 705 705 619 706 705 699 699 696 695 699 698 698 694 700 705 700 697 700 X5 629 695 692 687 721 715 716 720 713 704 710 707 710 712 702 709 716 709 700 704 713 710 640 702 643 706 706 706 643 707 706 705 700 699 695 695 699 699 697 697 702 705 700 696 698 X̄ 677.8 695.2 690.8 689.2 719.8 715.8 701.6 706.0 714.0 704.0 686.0 694.4 710.8 712.4 691.4 696.6 705.4 685.0 706.8 709.6 713.6 712.6 687.8 704.0 677.8 706.0 705.6 706.2 691.6 669.6 705.0 705.8 699.8 699.6 695.2 694.6 699.0 698.8 698.4 692.2 700.2 703.4 701.6 695.4 701.0 699.5 R 61 2 2 3 4 2 62 62 2 2 61 62 2 1 59 62 64 63 9 10 1 4 60 4 62 0 3 2 62 88 3 2 2 1 2 1 2 1 4 8 3 3 3 3 6 20.56 s 27.28 0.84 1.10 1.30 1.64 0.84 26.65 26.86 1.00 0.71 32.87 27.10 1.10 0.55 25.95 27.19 28.20 33.34 3.83 3.85 0.55 1.67 26.72 1.58 32.70 0.00 1.14 0.84 27.20 43.37 1.22 0.84 0.84 0.55 0.84 0.55 0.71 0.45 1.52 3.27 1.10 1.52 1.52 1.34 2.45 9.48